Horizontal strip hopper with elongated strip support carriage and passive center hook system

A strip and carriage technology, applied in the field of horizontal strip material storage, can solve the problem of completely passive system without the use of the center of the carriage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

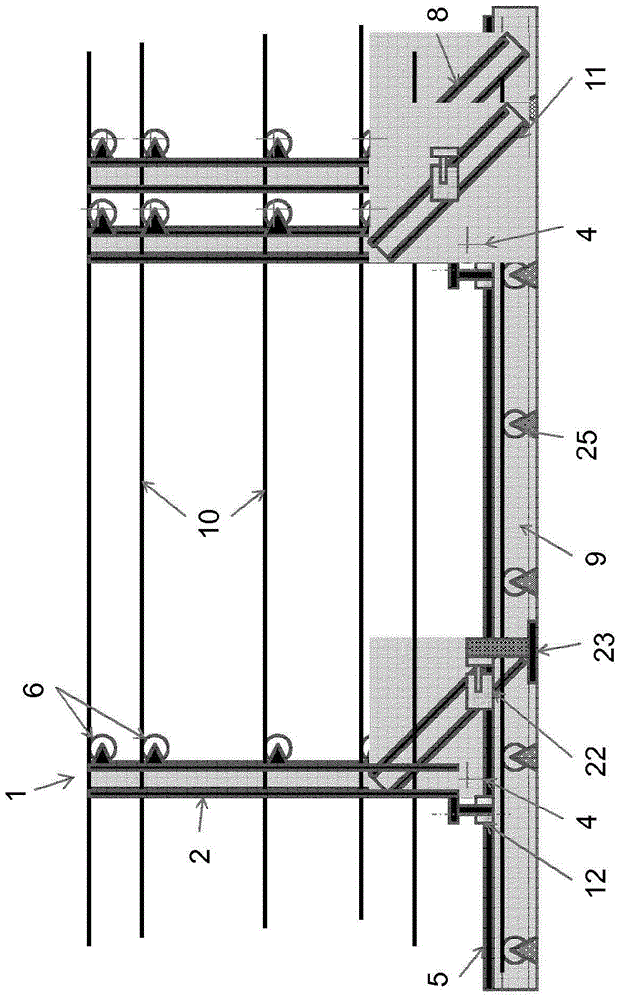

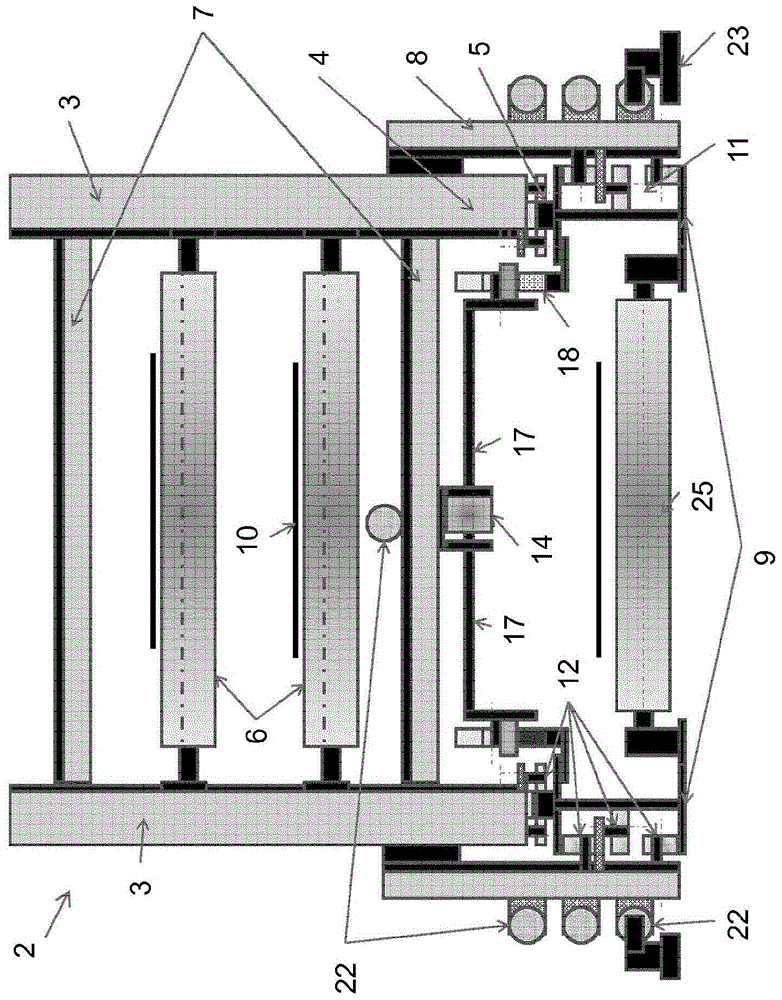

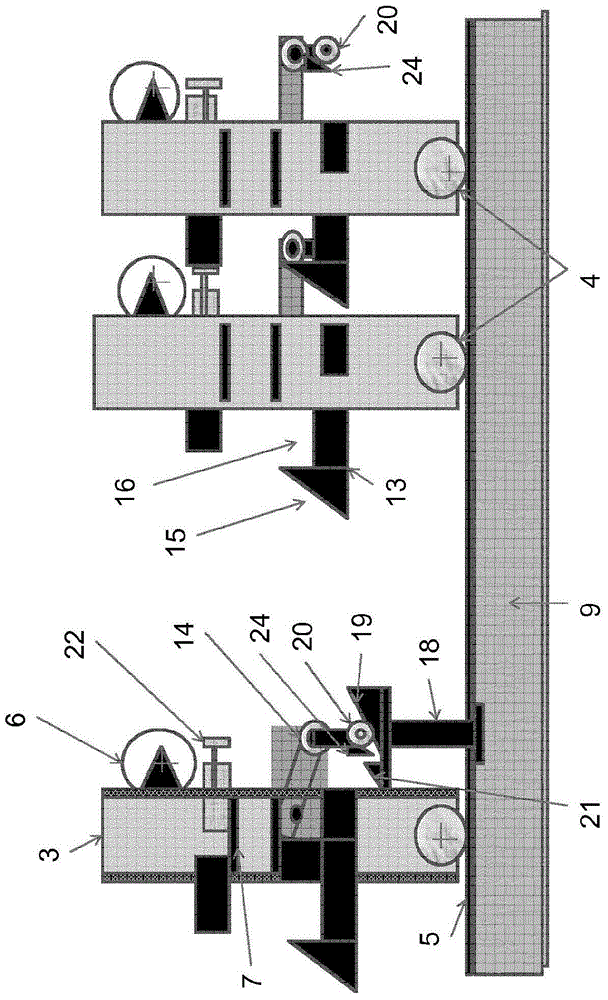

[0050] According to the preferred embodiment of the present invention ( figure 1 with 2 ), the horizontal stocker 1 comprises a strip support carriage 2 which in particular comprises a vertical frame 3 resting on two wheels 4 traveling on rails 5, so The track is identical to that of the stocker looper carriage (not shown). These vertical frames 3 are equipped with the necessary strip support rollers 6 . The lower carriage beam 7 of the vertical frame 3 is positioned so that it does not interfere with the strip looper 10 .

[0051] The forward movement of the loop carriage corresponding to the enlarged strip loop defines the sides of the carriage. The front side of the carriage corresponds to the side turning in the direction of moving forward or increasing the loop. The rear side of the carriage corresponds to the side that turns in the direction of moving backward or reducing the looper.

[0052] Brackets 8 are fixed on either side of the vertical frame 3 and at a given...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com