Low-temperature high-humidity unfreezing machine

A low-temperature, high-humidity, insulation layer technology, applied in the direction of freezing/cooling preservation of meat/fish, etc., can solve the problems of large water consumption, high water loss rate, and bacterial growth, and achieve uniform thawing and shortened thawing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

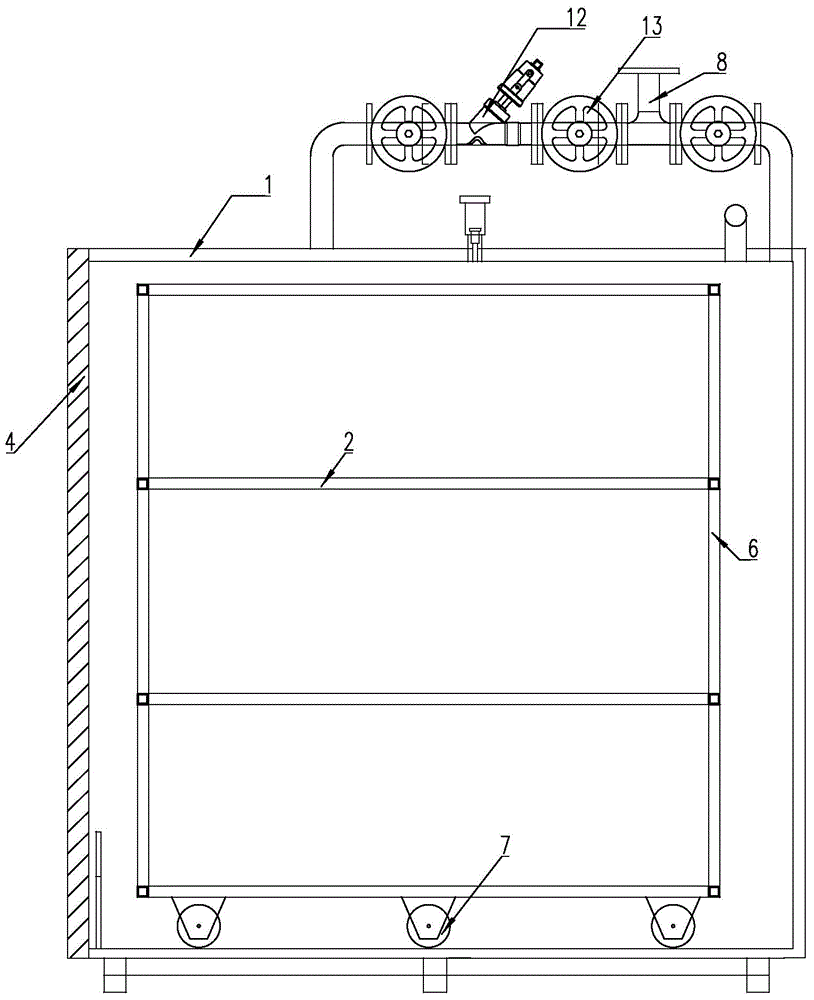

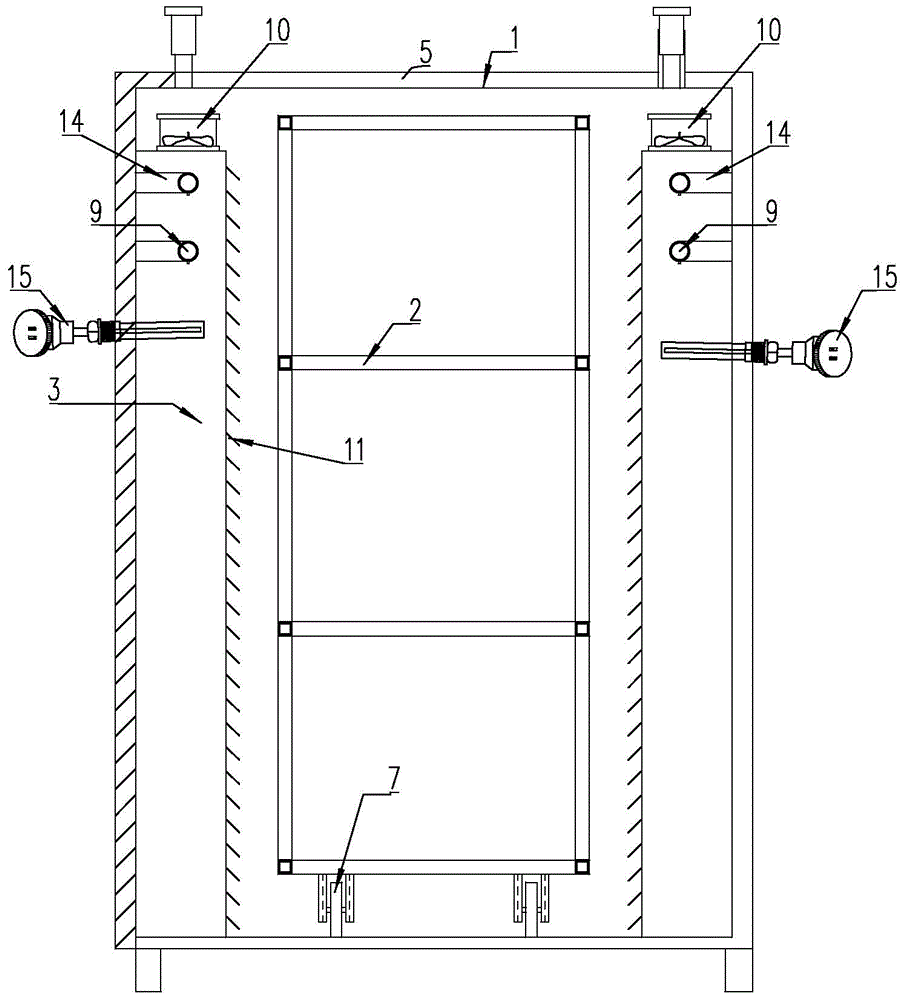

[0012] Such as figure 1 , 2 As shown, the low-temperature and high-humidity thawing machine includes a box body 1, a shelf 2 arranged in the box body 1, and a circulating humidification system 3 on both sides of the box body 1, and a sealed door with an insulating layer is arranged on the opening on one side of the box body 1. 4. The interior of the cabinet 1 is provided with an insulation layer 5, and the bottom of the frame body 6 on both sides of the shelf 2 is respectively provided with casters 7. The circulation humidification system 3 is composed of a steam system 8, a spray water pipe 9, a circulation fan 10 and an air volume adjustment shutter 11. Steam The system 8 is composed of a steam solenoid valve 12, a manual valve 13 and a steam exhaust pipe 14. The steam exhaust pipe 14 is respectively connected with the circulating humidification system 3 on both sides. The circulation fan 10 is located above the steam exhaust pipe 14 and below the steam exhaust pipe 14. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com