Freezing and thawing integrated cabinet and method for freezing and thawing using the integrated cabinet

An integrated, freezer technology, applied in the direction of freezing/cooling preservation of meat/fish, cooling fluid circulation device, application, etc., can solve the problem of poor freezing and thawing effects, not located in the same place, and increase contamination of food materials To reduce the time of transfer to the thawing room, improve efficiency and speed, and ensure that nutrients are not lost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

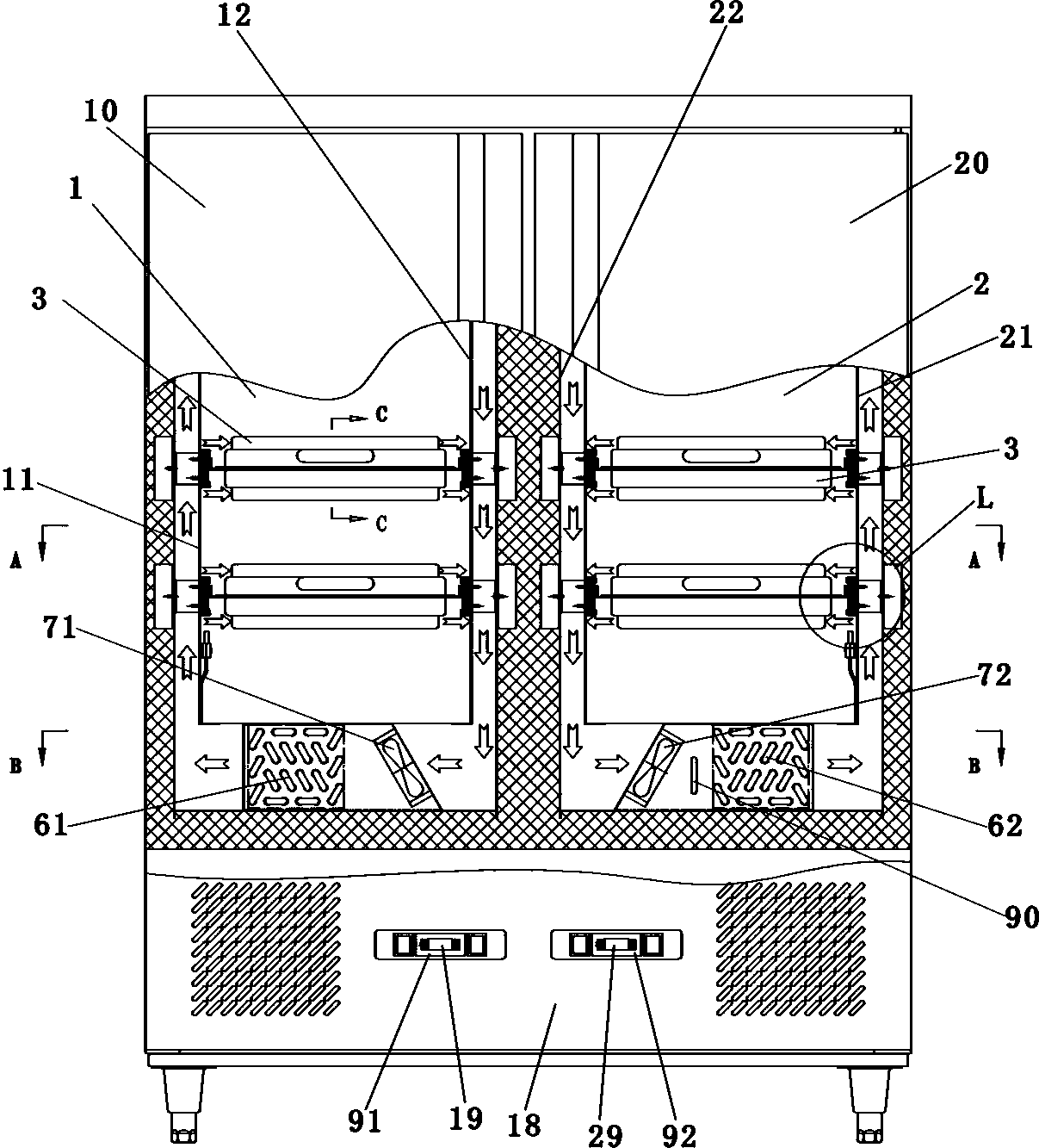

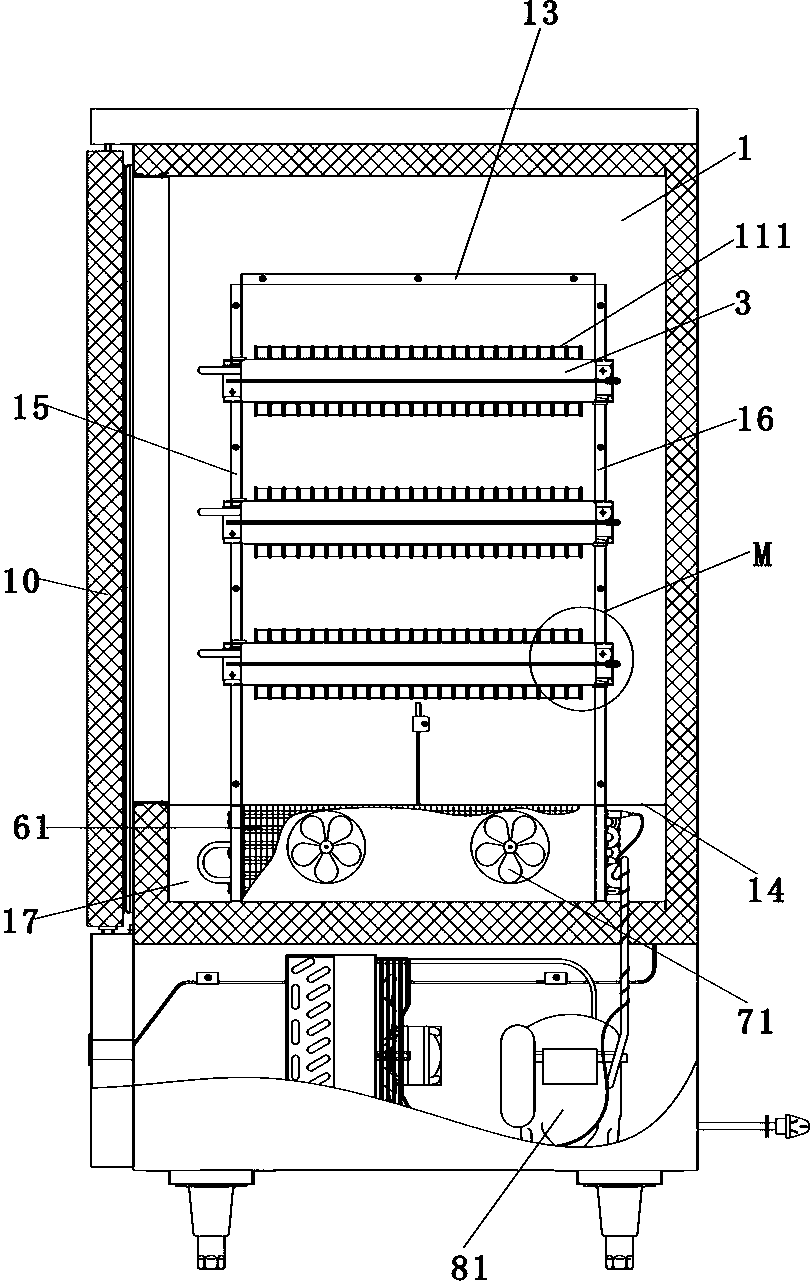

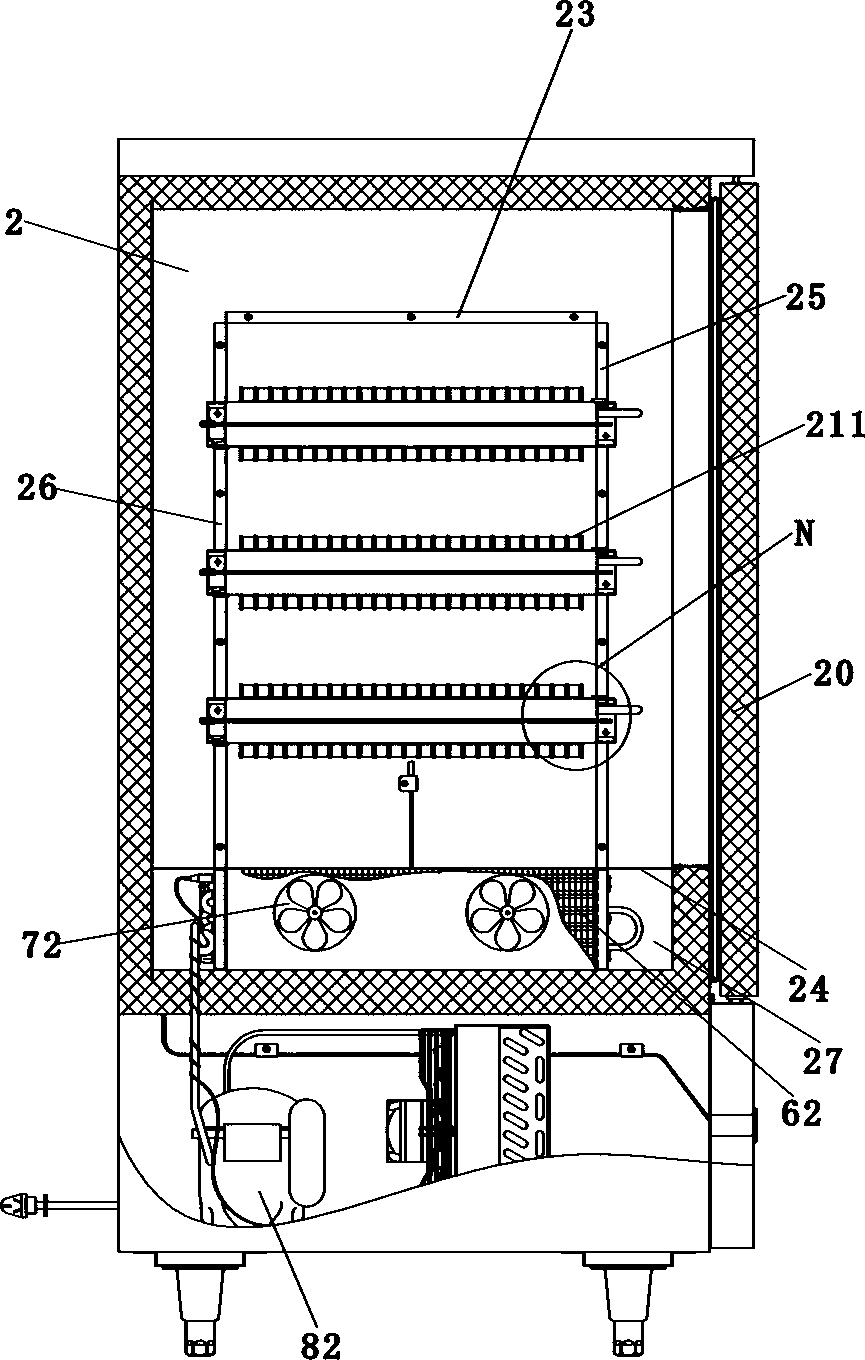

[0039] Such as figure 1 , 2 , 3, and 4, the freezing and thawing integrated cabinet of the present invention includes an insulated box body, and the insulated box body is divided into left and right two independent spaces, wherein one independent space is the freezing chamber 1, and the other independent space is the thawing chamber 2 , the freezing chamber and the thawing chamber are respectively provided with insulation doors 10 and 20 for sealing, and both the freezing chamber and the thawing chamber are fixed with box-shaped frames;

[0040] The left and right sides of the freezer frame are fixed with an air outlet channel plate 11 and an air return channel plate 12, the upper and lower sides and the front and rear sides are fixed with sealing plates 13, 14, 15, 16, and the air outlet channel plate is provided with an air outlet hole 111. The air duct plate is provided with return air holes corresponding to the position of the air outlet holes (not marked in the figure). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com