Reversed type horizontal magnetic field vertical ring high-gradient magnetic separator

A high-gradient magnetic separator, a horizontal technology, applied in the field of mineral processing machinery and equipment, to achieve large processing capacity, improve the separation effect, and solve the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

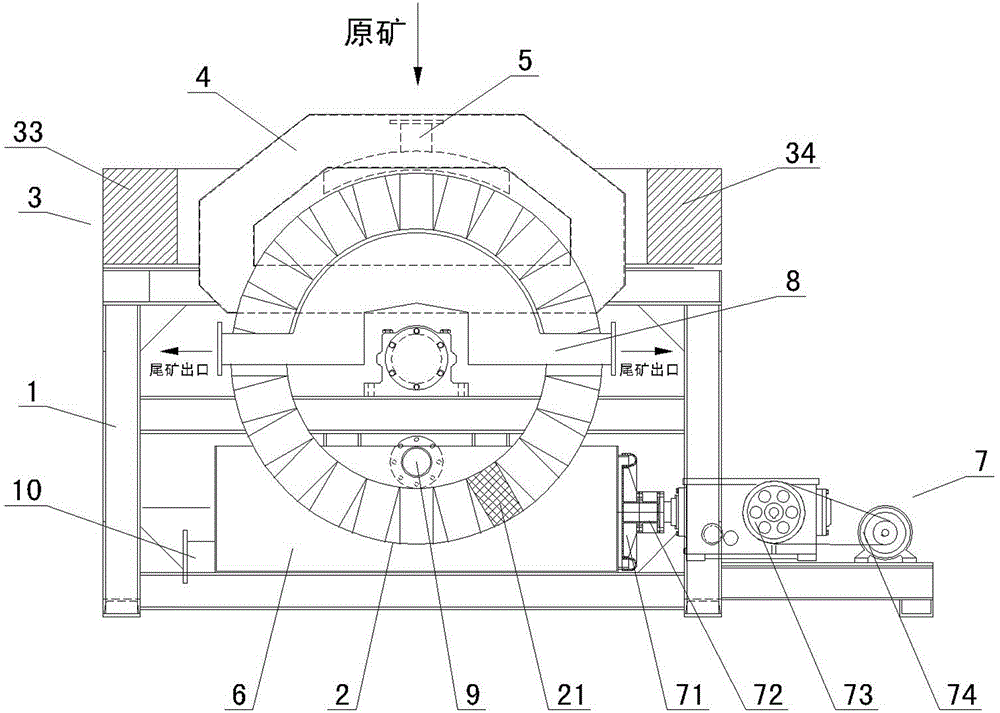

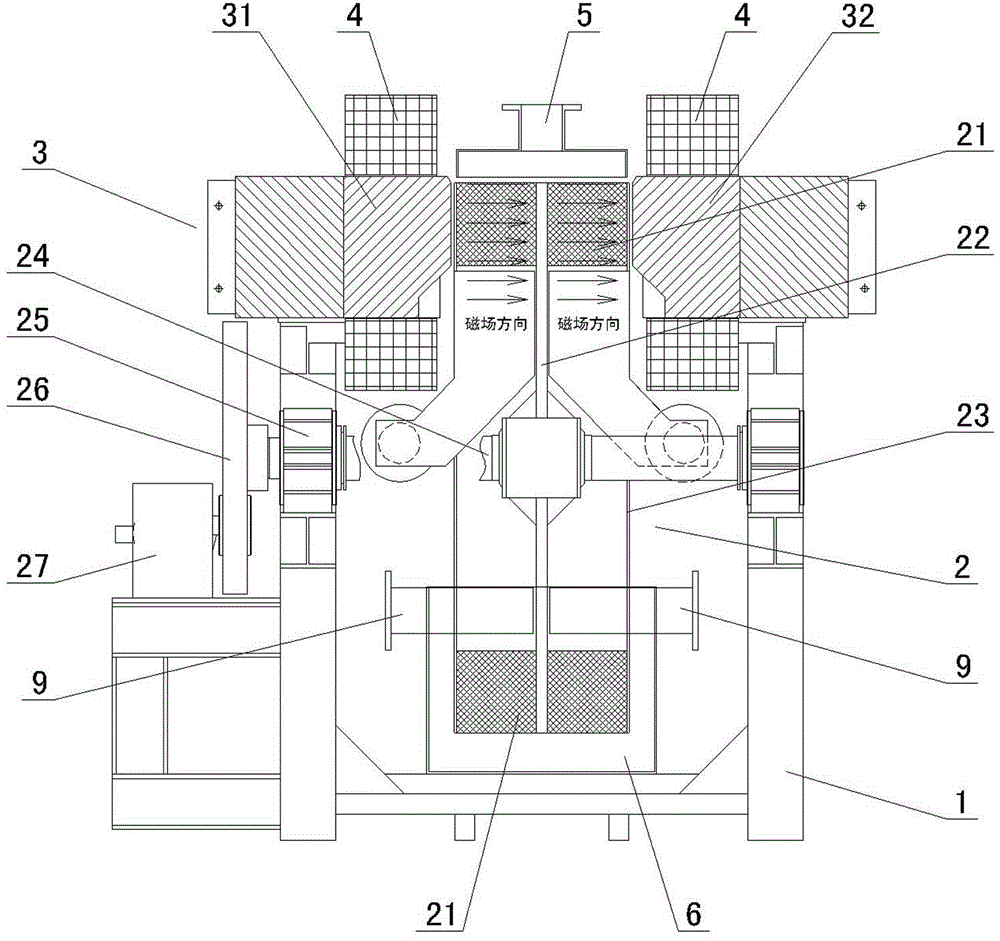

[0023] Such as Figure 1-Figure 2 As shown, the trans-type horizontal magnetic field vertical ring high gradient magnetic separator of the present invention mainly includes a frame 1, a swivel 2 containing a magnetic medium 21 rotatably connected to the frame 1, and a ring 2 arranged on the frame 1. The upper magnetic system device 3 with two magnetic pole heads, the coil 4 arranged on the magnetic system device 3, the ore hopper 5 arranged above the swivel 2, the bottom of the frame 1 and can accommodate the lower part of the swivel 2 The concentrate collecting bucket 6, the water flow disturbing device 7 arranged on the frame 1 and connected with the concentrate collecting bucket 6, and the tailings collecting bucket 8 arranged on the frame 1, wherein the magnet at the bottom of the swivel 2 The medium 21 can be soaked under the water surface in the concentrate collecting bucket 6, and the upper part of the concentrate collecting bucket 6 is provided with a discharge water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com