Heavy metal dangerous waste in-situ storage and underground water pollution prevention method

A technology for groundwater pollution and heavy metals, which is applied in the fields of reduced water/sewage treatment, polluted groundwater/leachate treatment, solid waste removal, etc., can solve the problems of secondary development of heavy metals, surface water and groundwater pollution, etc., and achieve Good protection function, low cost of prevention and control, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

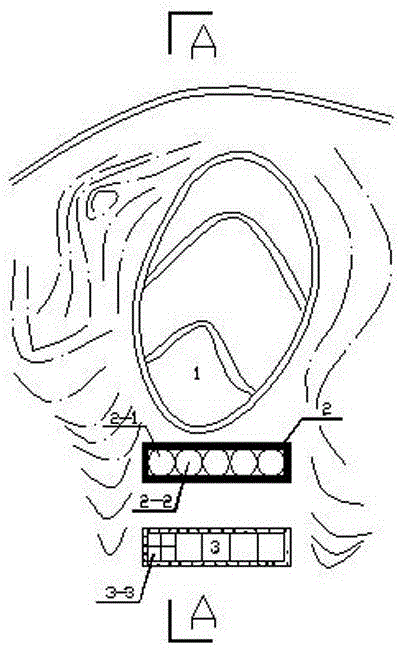

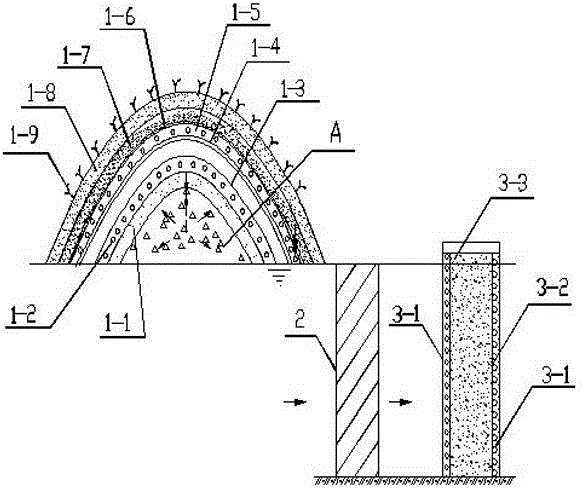

[0036] Such as figure 1 , figure 2 As shown, a method for in-situ storage of heavy metal hazardous waste and prevention and control of groundwater pollution according to the present invention firstly seals and covers the original heavy metal hazardous waste pile in the valley to form a closure and covering system 1; The vertical anti-seepage curtain 2 is used to initially block the polluted groundwater after the site is closed; finally, according to the direction of water flow, a permeable reaction wall 3 is set below the vertical anti-seepage curtain to repair groundwater pollution;

[0037] The site closure and covering system 1 is respectively set up from the original heavy metal hazardous waste pile A from bottom to top:

[0038] The clay barrier layer 1-1 is compacted clay with a thickness of 500mm. The main function is to prevent precipitation from penetrating into the original heavy metal hazardous waste pile and to control the migration and diffusion of gases.

[0...

Embodiment 2

[0055] Heavy metal hazardous waste left over from history in a certain city is piled up in a valley. The hazardous waste has not grown grass for many years. The average annual precipitation in the area is between 1200-1700mm, and the altitude is close to 1280m. Within a radius of 50km, there are steep mountainous areas with a large vertical drop between the top of the mountain and the bottom of the mountain. The maximum vertical distance is close to 200m, and the mountain road is rugged. According to the results of field investigation, the surface length, width and depth of the hazardous heavy metal waste left over from history are about 280×130×12m, and the content is preliminarily estimated to be at least one million tons.

[0056] According to the on-the-spot survey, the main source of hazardous waste is waste residues such as indigenous gold smelting, indigenous zinc smelting, and indigenous steelmaking since the 1960s. The detected lead concentration is 4.10mg / L, zinc conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com