Method and device for absorbing, recovering and purifying organic from exhaust gas

A technology for adsorption and recovery of organic matter, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of affecting the quality of recycled materials, it is difficult to achieve desorption effect, and there are not many desorption applications, so as to facilitate condensation Separation, easy refining and recovery, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

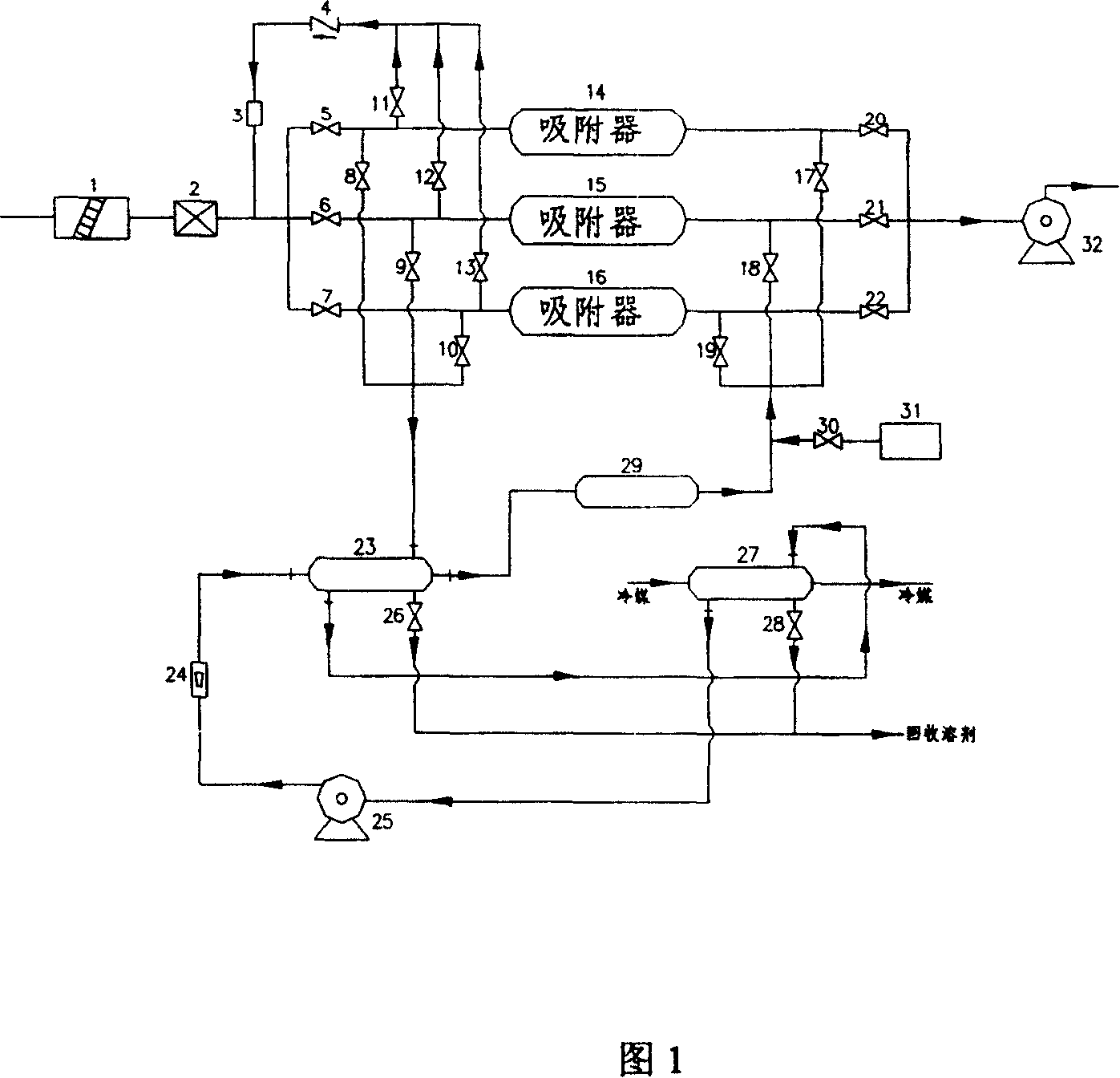

[0025] Embodiment 1, the following components are connected in the manner shown in Figure 1, and those skilled in the art can implement it smoothly. The device of the present invention consists of a gas filter adopting AF10-N type, a flame arrester adopting mesh type HGS07, three adsorbers filled with adsorbent adopting CAU10-G type, a main fan adopting BF9-26NO8D type, and a thermal The exchanger adopts AAE-10-B type, one circulation air heater adopts GL-10 type, one gas condenser adopts TLS-50-400-480 type, one circulation fan adopts BF9-26 type, and supplements the gas source Nitrogen is used, the oxygen content measurement probe adopts TB2A zirconia oxygen probe, the automatic control system adopts PRC program controller, and the model of the program-controlled valve is KVD pneumatic disc valve.

[0026] When the system is running, the exhaust gas containing DMAC is removed from the particulate matter by the filter 1, and then enters the subsequent recovery and regeneratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com