Crude benzene distilling and washing oil regenerating heating system and method

A crude benzene distillation and heating system technology, used in flash evaporation, petroleum industry, removal of gas pollutants, etc. The effect of reducing operating costs, saving energy and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

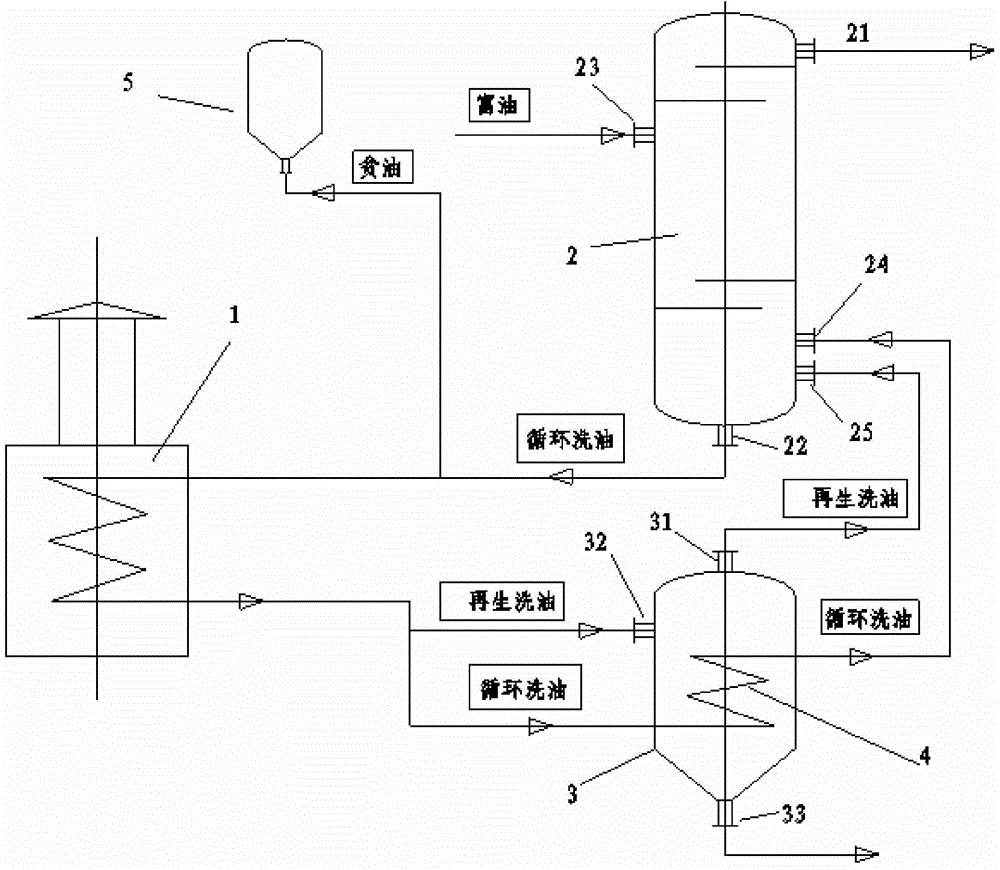

[0025] A crude benzene distillation and washing oil regeneration heating system, see figure 1 , including a heating furnace 1, a debenzene tower 2, a regenerator 3, and a heater 4, the top of the debenzene tower 2 is provided with an oil vapor outlet 21, the bottom is provided with an oil outlet 22, and the upper part is provided with a washing oil (oil-rich) inlet 23. The oil outlet at the bottom is connected to the oil inlet of heating furnace 1 through pipelines, the oil outlet of heating furnace 1 is connected to the inlet of heater 4 through pipelines, and the outlet of heater 4 is connected to the oil inlet 24 at the bottom of debenzene tower 2 through pipelines connected; the top of the regenerator 3 is provided with a regenerated washing oil inlet 32, the top is provided with a regenerated oil vapor outlet 31, and the bottom is provided with a residual oil outlet 33, and the regenerated washing oil inlet 32 is connected with the oil outlet of the heating furnace 1 thr...

Embodiment 2

[0036] use figure 1 The flow process of a kind of crude benzene distillation and washing oil regeneration heating process:

[0037] Coking plant gas purification system gas 40000m 3 / h, washing benzene washing oil 72m 3 / h, the specific implementation is as follows:

[0038] 1. 72m from the benzene washing system 3 / h washing oil (rich oil) enters the middle part of the debenzene tower 2, and the oil vapor of the debenzene tower 2 goes out from the top;

[0039] 2. Circulating oil washing with a flow rate of 147m 3 / h, temperature 210°C flows out from the bottom of debenzene tower 2, part of which is 72m 3 The flow rate of / h is used as washing oil (lean oil) to send to the washing system, and the other part is sent to the benzene washing system with a flow rate of 75m 3 / h is sent to the heating furnace 1 as a circulating washing oil for heating to obtain the heat required for the regeneration of the washing oil and the removal of benzene;

[0040] 3. The high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com