A frame hollow core tube structural system of a high-rise building

A technology for high-rise buildings and core tubes, applied in building components, building structures, buildings, etc., can solve the problems of core tubes with many shear walls, heavy weight, and poor economic efficiency, so as to increase building flexibility and reduce weight , the effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

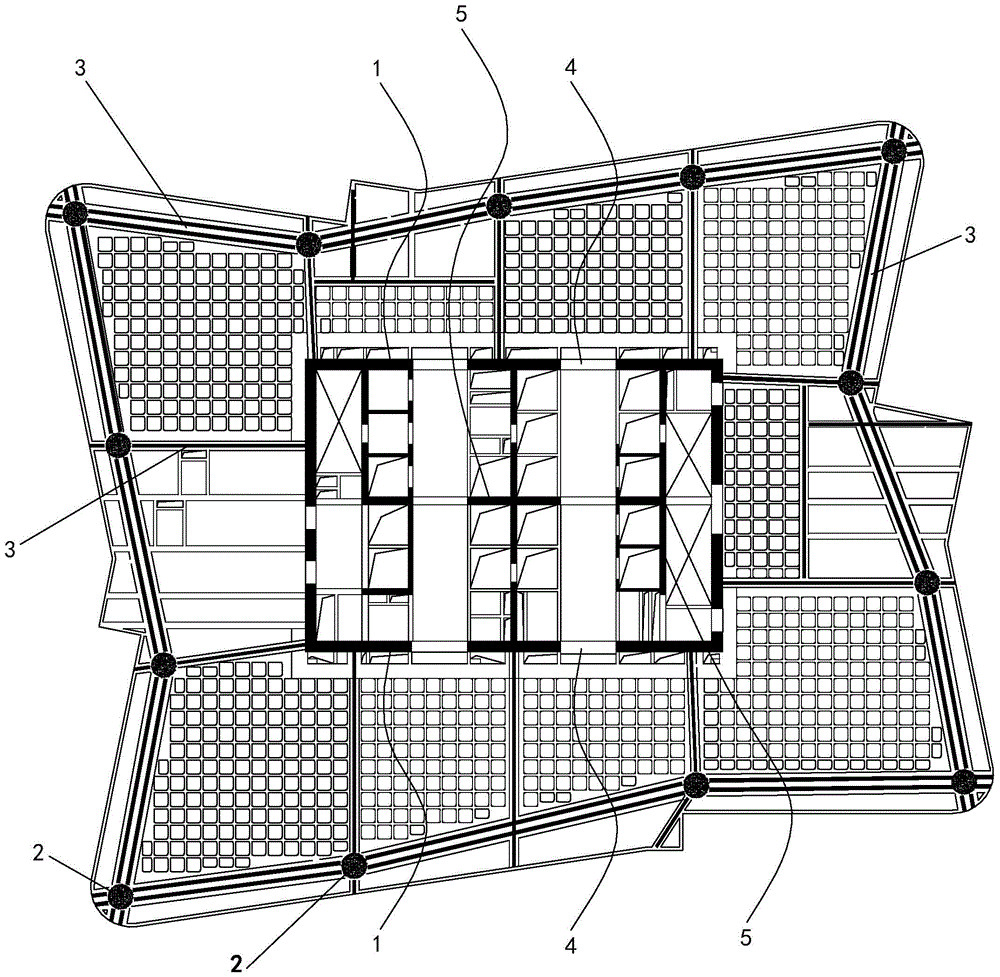

[0044] An embodiment of the frame hollow core tube structural system of a high-rise building of the present invention is as follows Figure 2 to Figure 5 As shown, the number of floors of a high-rise building is 50. The structural system includes shear walls 1, connecting beams 4, peripheral columns 2, frame beams 3 and floor slabs. The shear walls 1 are vertically arranged and located at the center of the high-rise building , the shear wall 1 is a plurality of pieces vertically arranged, and the connecting beam 4 is erected between the adjacent shear walls 1, and the shear wall 1 and the connecting beam 4 are surrounded to form a rectangular hollow core tube, and the peripheral columns 2 are located at At the periphery of the hollow core tube, the peripheral columns 2 are multiple vertically arranged steel pipe concrete columns, and the frame beams 3 are also multiple. Some frame beams 3 are erected between the peripheral columns 2 and the shear walls 1, and the remaining fram...

Embodiment 2

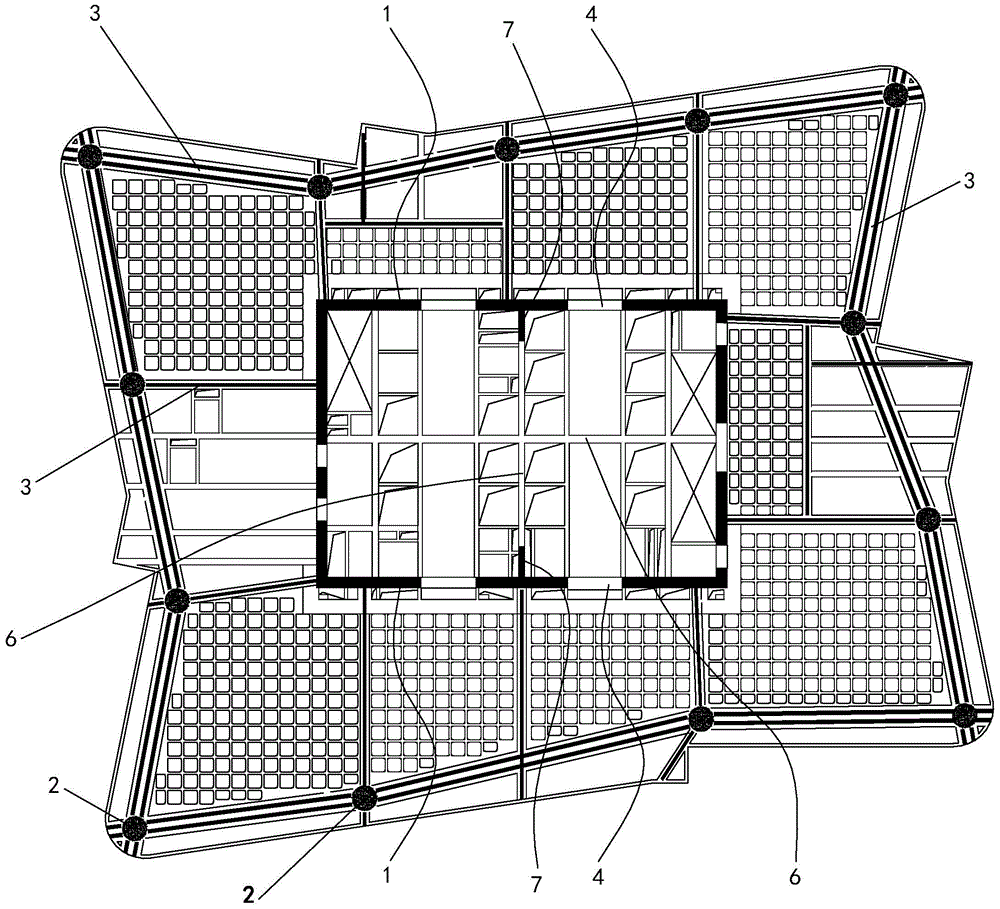

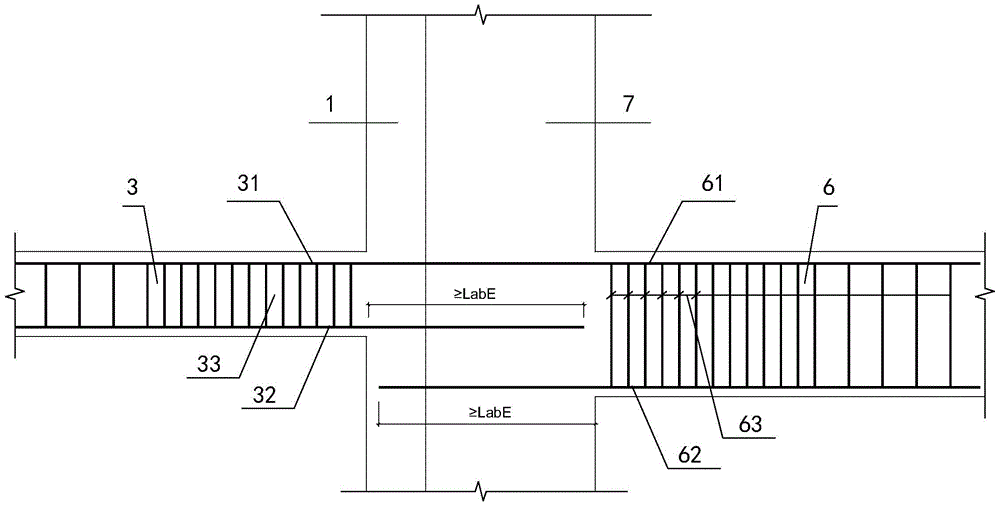

[0060] A second embodiment of the frame hollow core tube structural system of a high-rise building of the present invention is as follows Figure 6 to Figure 8As shown, the difference from Embodiment 1 is that there are four wall limbs 7 in this embodiment, which are respectively located on the four sides of the inner surface of the hollow core tube, and are symmetrically distributed around the center line of the hollow core tube. , the frame beams 3 on both sides of the wall 7, the inner beam 6 and the wall 7 are all located on the same straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com