Formed floor slab which can be assembled into ceiling

A technology for ceilings and floors, which is applied to floors, building components, and earthquake resistance, and can solve the problems of long construction period, heavy construction workload, troubles, etc., and achieve the effect of saving resources and wealth and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

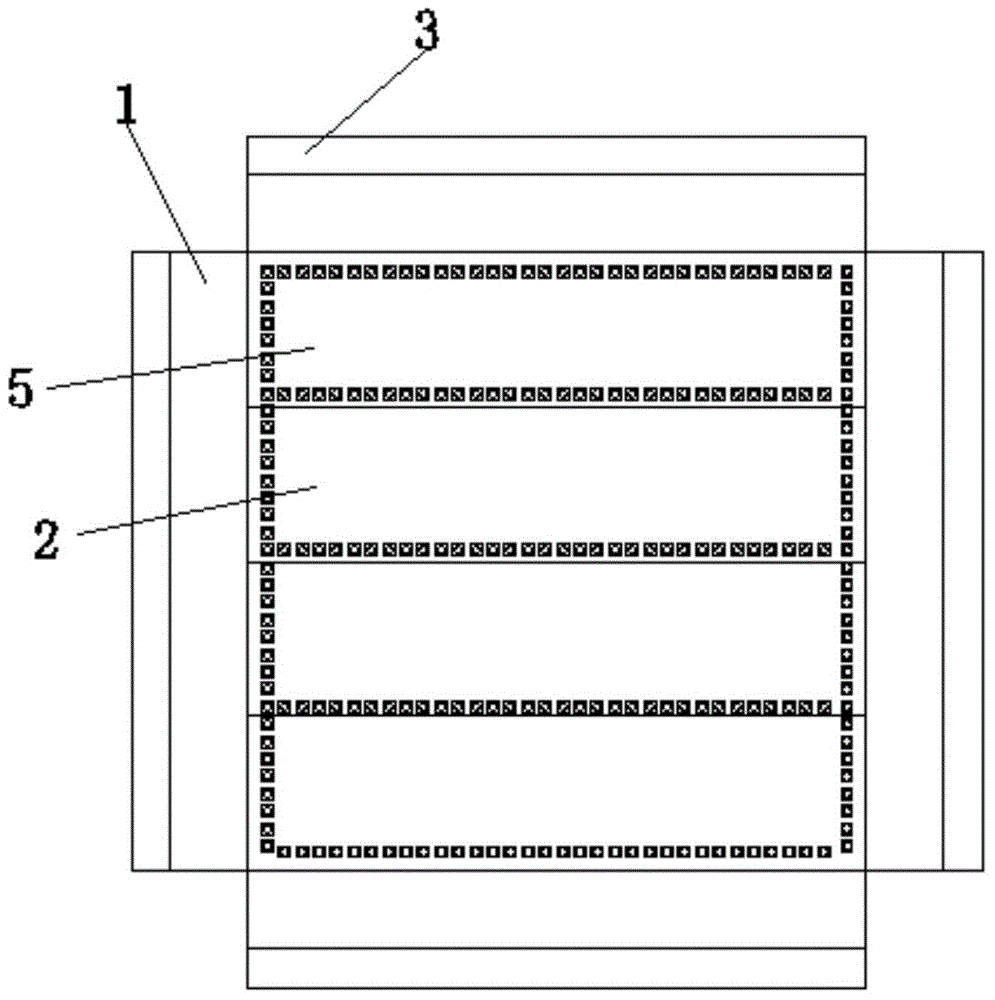

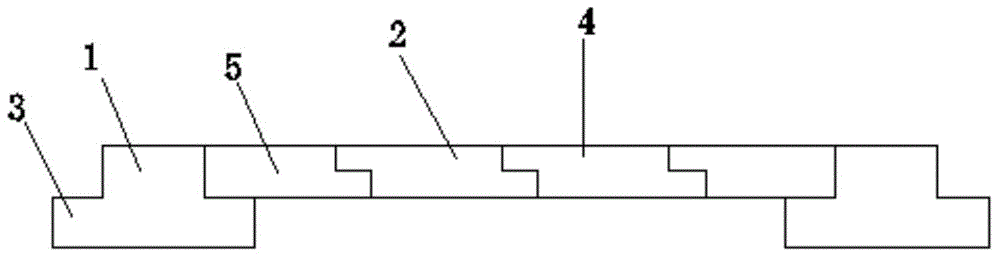

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

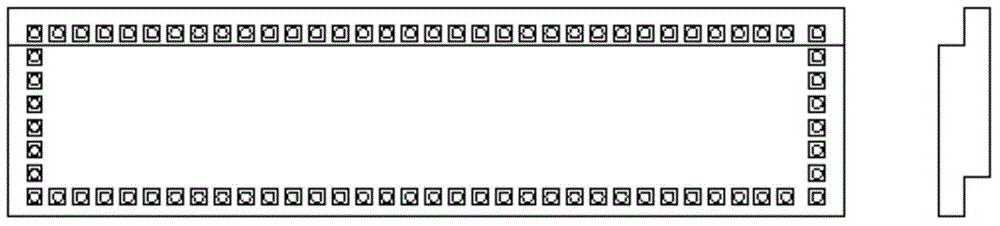

[0021] A floor slab that can be assembled into a ceiling shape, including a beam 1 and a floor 2, is characterized in that: the two sides of the beam 1 are provided with raised strips 3, and the raised strip 3 is provided with a through hole 4, and the floor slab 2 There are through holes 4 all around.

[0022] The floor slab 2 and the beam 1 are connected by bolts.

[0023] The floor 2 is divided into a standard floor 5 and a special floor 6.

[0024] Both ends of the standard floor 5 are provided with interfaces, and one end of the special floor 6 is provided with interfaces.

[0025] The bolts are countersunk head bolts with a square head and a diameter of more than 1 cm.

[0026] The upper and lower surfaces of the floor slab are inlaid with ceramic tiles, and the back of the tiles has several mushroom-shaped protrusions, which can be poured into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com