Liquid exhaust pipe purifier

A technology for exhaust pipes and purifiers, applied in the field of purifiers, which can solve the problems of shortening the service life of exhaust pipes, aggravating the aging of catalysts, and reducing catalytic efficiency, etc., and achieve the effects of prolonging service life, exquisite structure, and reducing high-temperature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

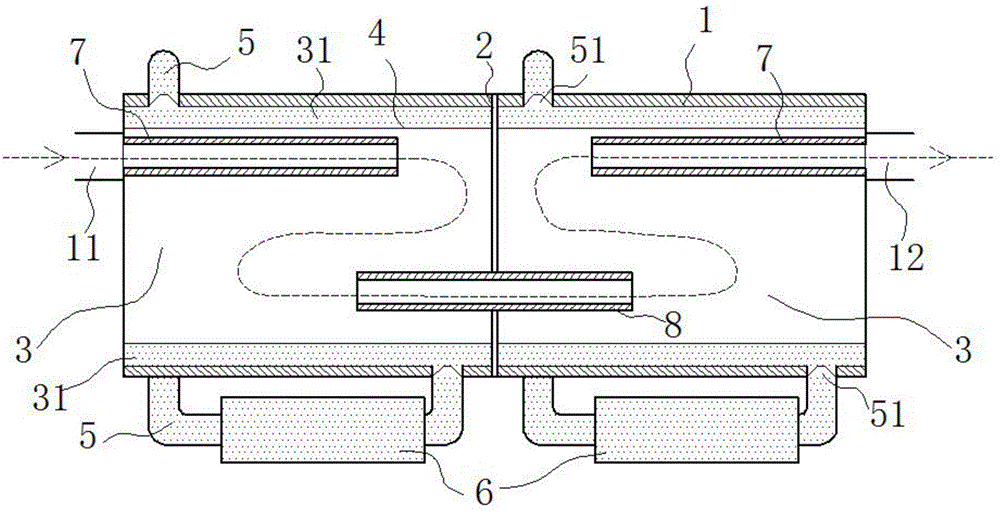

[0013] exist figure 1 In the shown embodiment, the liquid exhaust pipe purifier includes an air inlet 11, an air outlet 12 and a cylindrical shell 1, the outer wall of the shell 1 is coated with an insulating layer; the shell The body 1 is divided into two closed expansion chambers 3 by an insulating partition 2 perpendicular to the axis of the housing 1; Elastic net tube 4, the mesh aperture of the net tube 4 reaches the level of liquid seal; in the airtight purification ring tube surrounded by the shell 1, the partition plate 2 and each of the net tubes 4 31 is filled with purification liquid; each of the purification ring cylinders 31 is connected to the elastic cooling box 6 made of transparent material through two liquid guide tubes 5 locked by a one-way valve 51, each of the purification ring cylinders 31 and each The elastic cooling box 6 forms a sealed circuit through the guide pipe 5; metal guides parallel to the axis of the housing 1 and extending toward the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com