Cooling exhaust pipe

A technology for exhaust pipes and coolers, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., which can solve the problems of blocked components, difficult installation and maintenance, and increased costs, and achieve the goals of preventing damage, simple structure, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

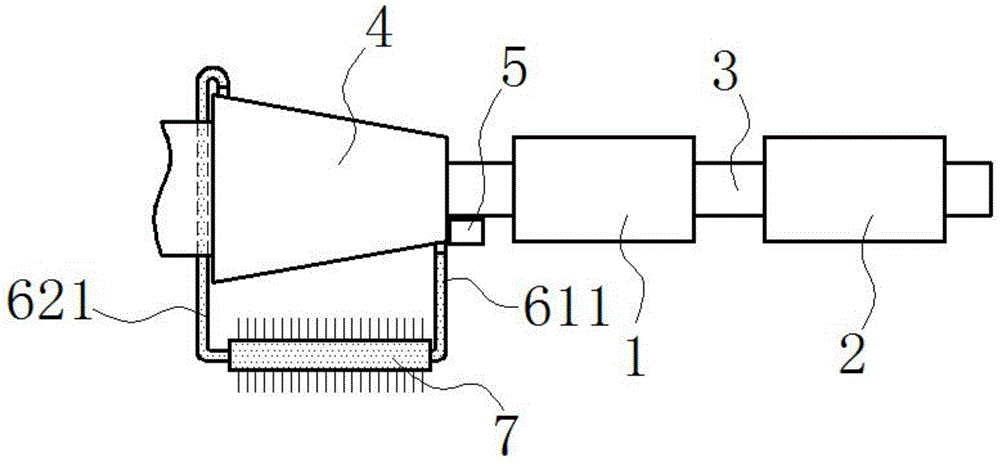

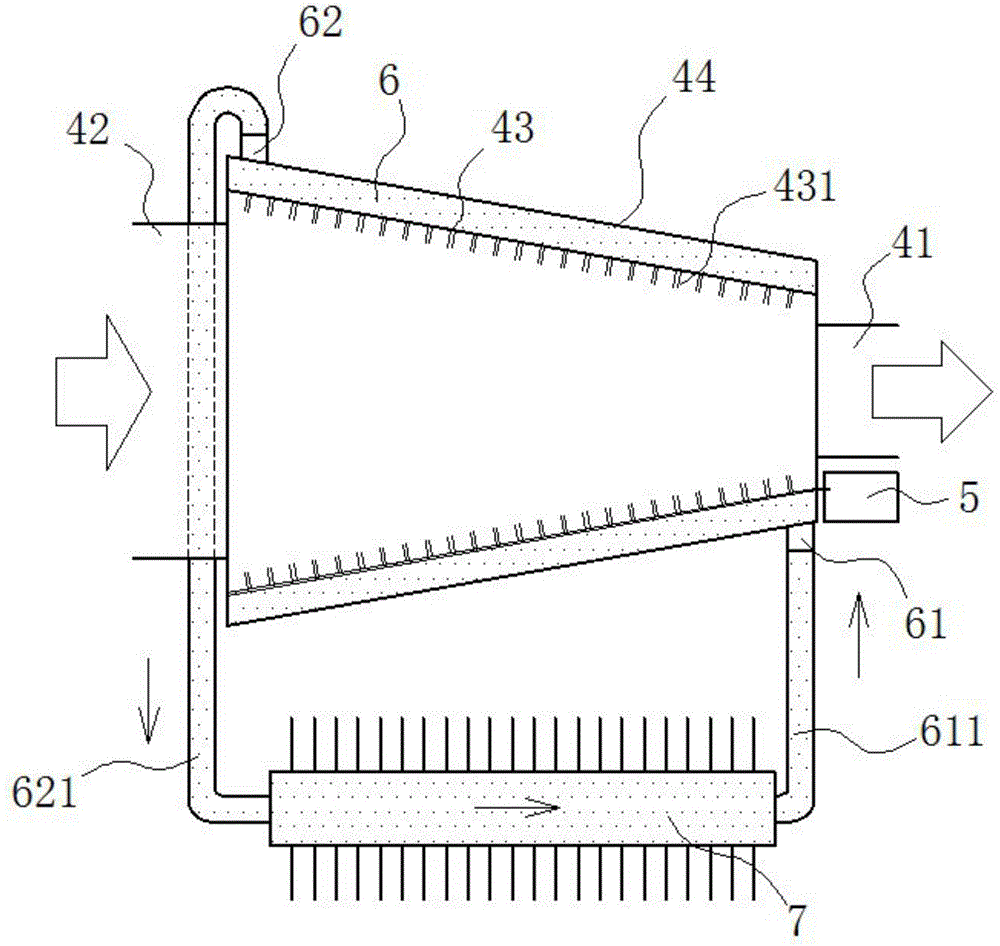

[0013] exist figure 1 , figure 2 In the shown embodiment, the cooling exhaust pipe includes a purifier 1, a muffler 2 and an air guide pipe 3; the purifier 1 and the muffler 2 are sequentially connected in series on the exhaust port of the engine by the air guide pipe 3 A cooler 4 is also connected in series between the exhaust port of the engine and the purifier 1; the cooler 4 is a tapered double-layer hollow tubular structure, and the aperture of the outlet end 41 of the cooler 4 is smaller than the inlet The aperture of the air end 42; the inner tube 43 of the cooler 4 is made of an elastic material, and the outer tube 44 is made of a hard material; on the inner wall of the inner tube 43, water-absorbing plush is also adhered Layer 431, the water-absorbing plush layer 431 stretches out of the outer tube 44 of the cooler 4 and stretches into a negative pressure liquid collection tank 5, and the water-absorbing plush layer 431 and the outer tube 44 reach an airtight state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com