Outer sleeve seal head

A technology of sealing head and outer casing, which is applied in the direction of pipe/pipe joint/fitting, pipe protection, pipe protection through heat insulation, etc., can solve the problem of wasting protective pipe, etc., and achieve the effect of high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

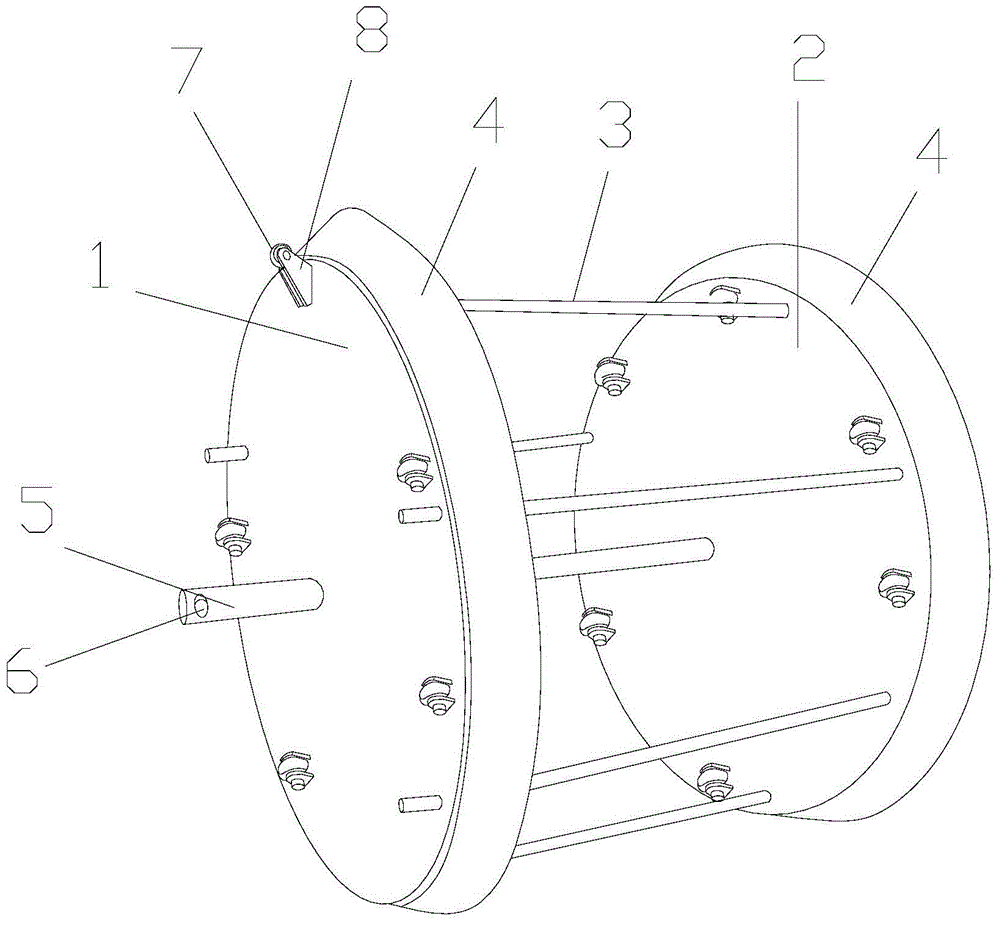

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a sealing head of an outer sleeve includes an upper baffle 1 and a lower baffle 2, the upper and lower baffles are connected by a connecting rod 3, and the rear sides of the upper and lower baffles are respectively affixed with hard A hard foam layer 4, the diameter of the hard foam layer is larger than the diameter of the upper and lower baffles, and the hard foam layer can be tightly attached to the inner wall of the outer casing, thereby achieving the purpose of blocking. In order to facilitate pulling and sealing, a pull rod 5 is provided in the middle of the upper and lower baffles, and a rope fixing hole 6 is provided at the front end of the pull rod. Pull the whole air seal through the rope through the rope fixing hole, so that the air seal can move in the outer casing. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap