Ultra-supercritical coal-fired boiler unit start adjusting method and system

A coal-fired boiler, ultra-supercritical technology, applied in the field of combustion boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

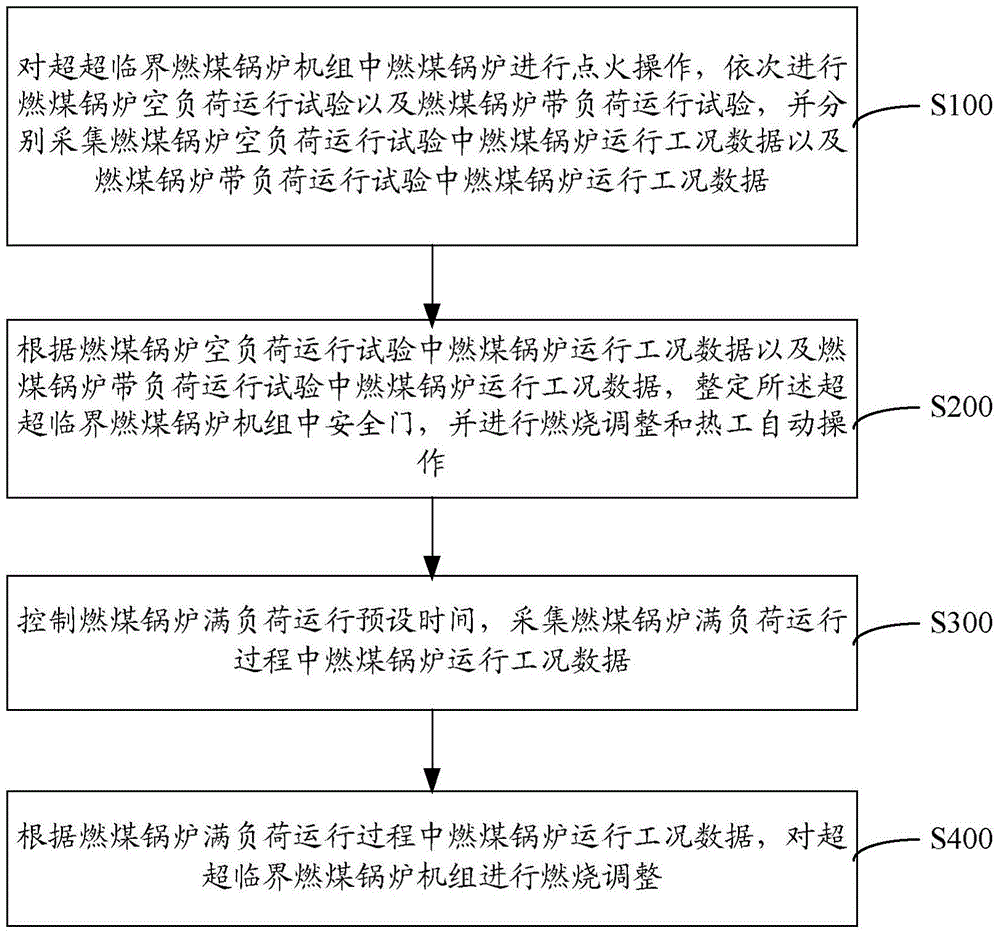

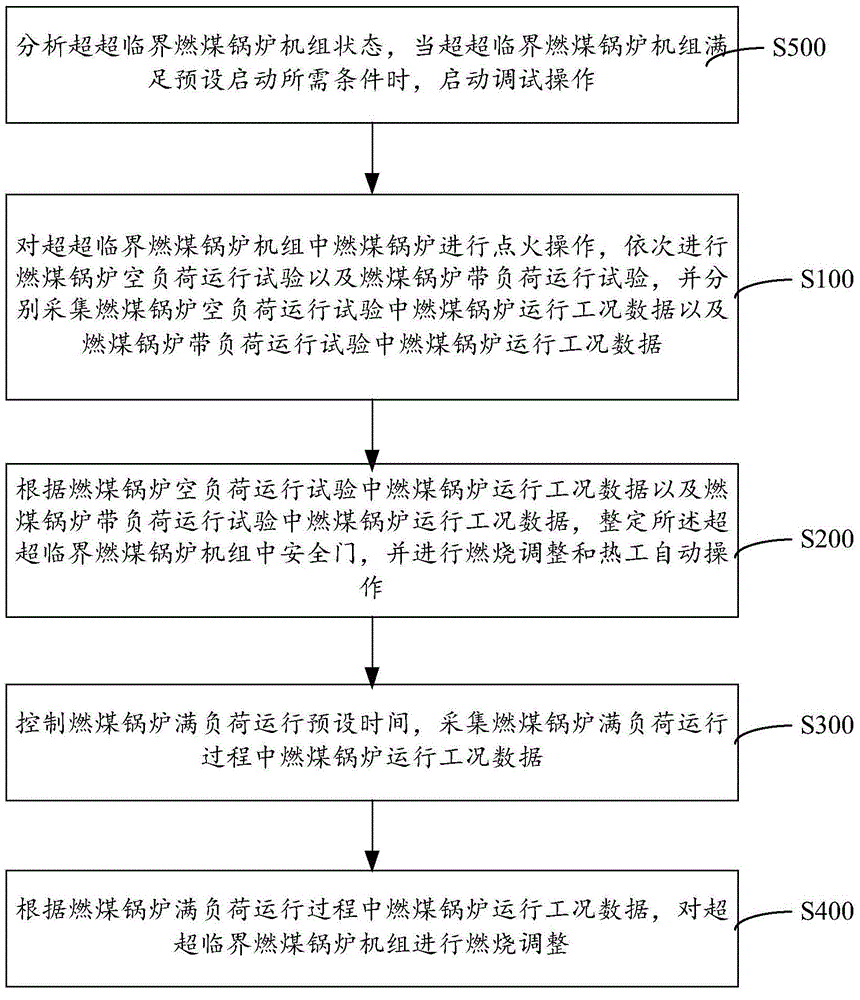

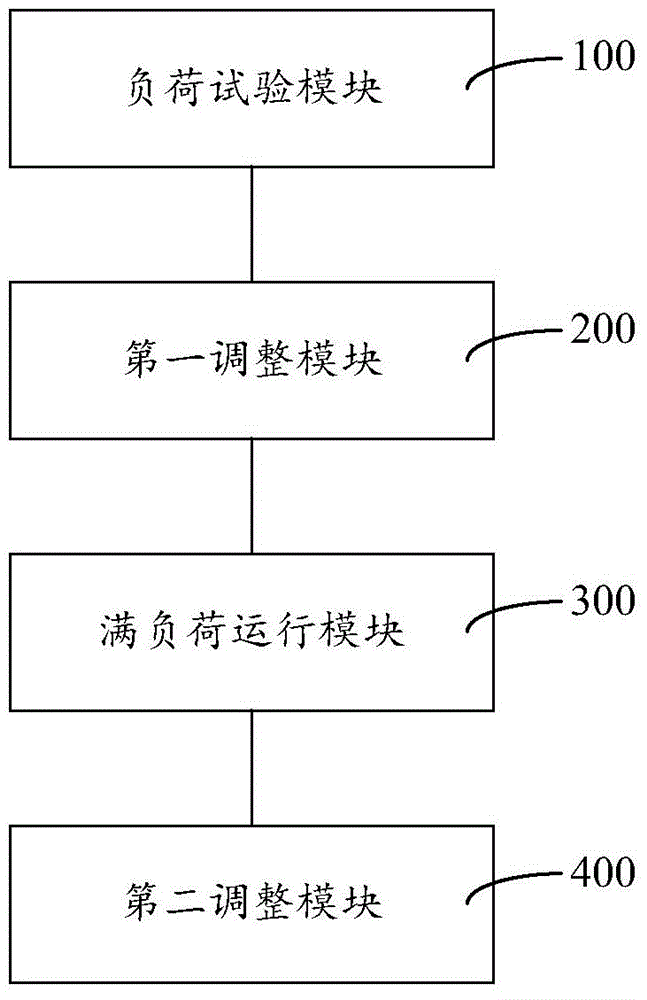

[0021] In order to explain in detail the technical scheme of the start-up and debugging method of the ultra-supercritical coal-fired boiler unit of the present invention and the effects thereof, in the following explanations, an existing ultra-supercritical coal-fired boiler unit will be mainly used as the research object to describe. In this ultra-supercritical coal-fired boiler unit, the coal-fired boiler is a 2×1050MW unit of China Resources Power (Haifeng) Co., Ltd. The boiler model is HG-3100 / 28.25-YM4. The boiler is an ultra-supercritical once-through boiler with variable pressure operation. Type layout, single furnace, intermediate reheating, low NOX main burner and high-level burn-off air staged combustion technology, reverse double tangential combustion mode, the furnace is a vertically rising membrane water-cooled wall with internal threaded tubes, and the atmosphere expansion start-up system ; In addition to the coal / water ratio, the temperature adjustment method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com