Liquid distributor

A liquid separator and straight pipe technology, applied in the field of compressor equipment, can solve problems such as inability to fix straight pipes, fatigue failure of connecting parts, etc., and achieve the effects of small working vibration amplitude, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

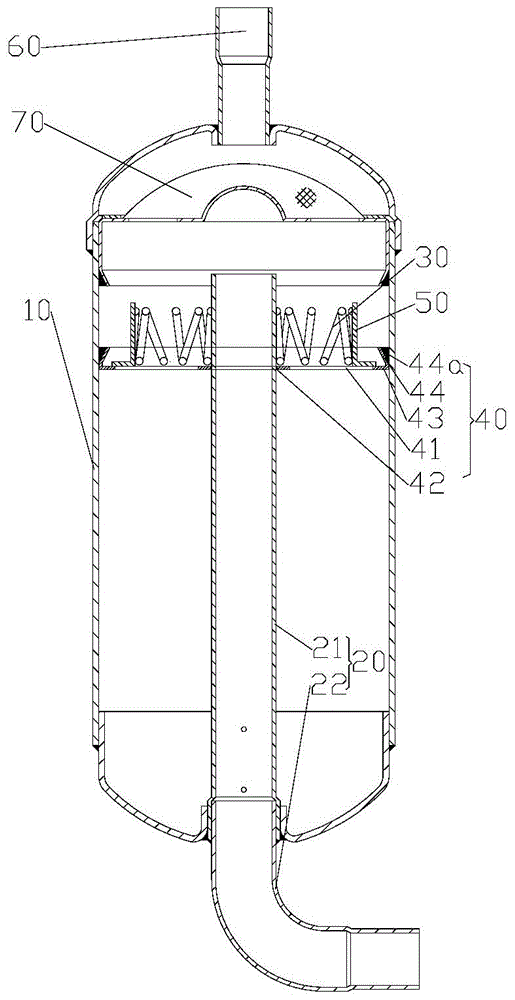

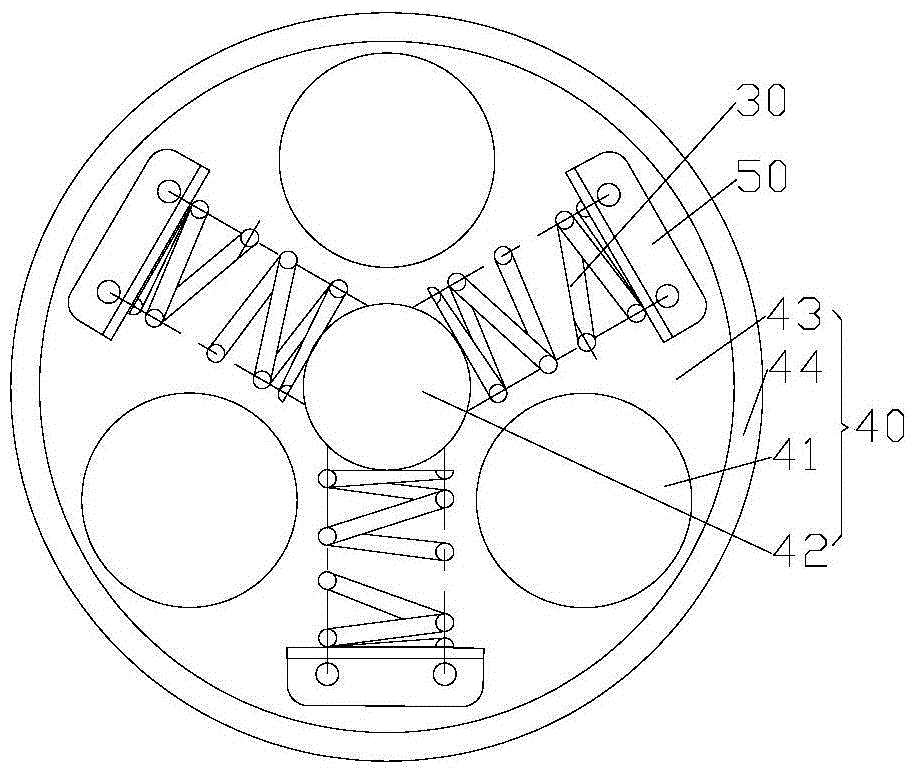

[0021] The invention provides a liquid separator. like figure 1 and figure 2 As shown, the liquid separator includes a housing 10, an exhaust pipe 20 and a flexible support 30. The exhaust pipe 20 includes a straight pipe 21 arranged in the housing 10, and the flexible support 30 is arranged between the housing 10 and the straight pipe 21. The vibration of the straight pipe 21 is buffered between them. Since the housing 10 is connected to the straight pipe 21 through the flexible support 30, the limiting effect of the flexible support 30 on the straight pipe 21 is effectively ensured, and the vibration of the straight pipe 21 due to the suction pulsation is effectively absorbed by the flexible support 30 , so as to ensure that the straight pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com