Measuring method and fixture used for measuring blade internal structure

A measuring method and technology of measuring part, applied in the field of compound optical coordinate machine measurement, can solve the problem of inability to accurately measure the contour and size of turbine blade spoiler column and rib structure, achieve good repeatability and accuracy, reduce projection effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. (Note optional and preferred mixed use)

[0025] Unless otherwise specified, the technical means used in the embodiments are conventional means well known to those skilled in the art.

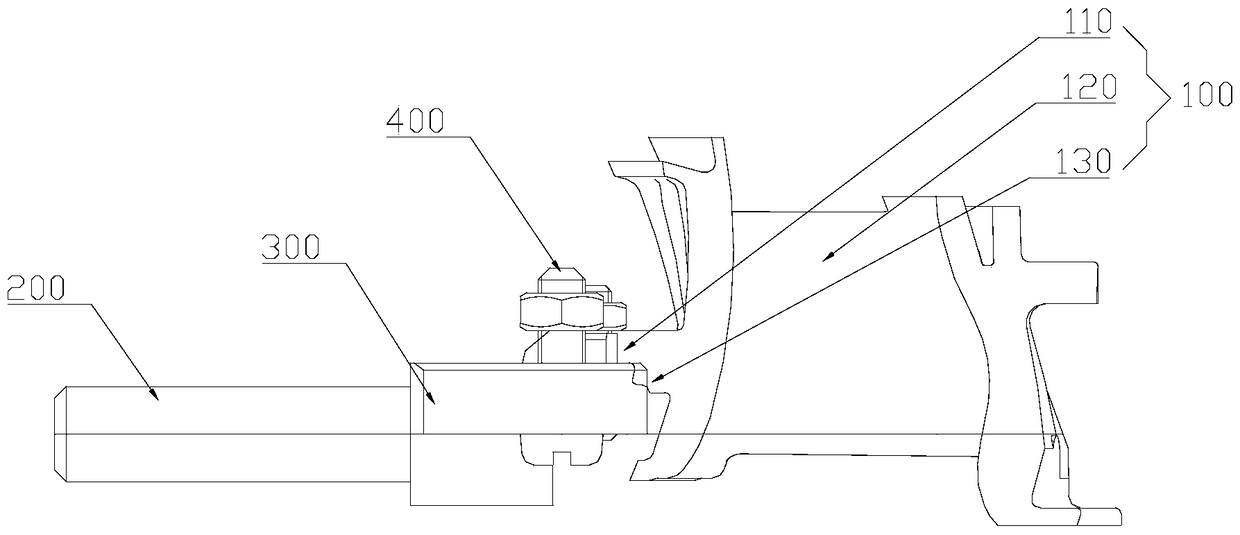

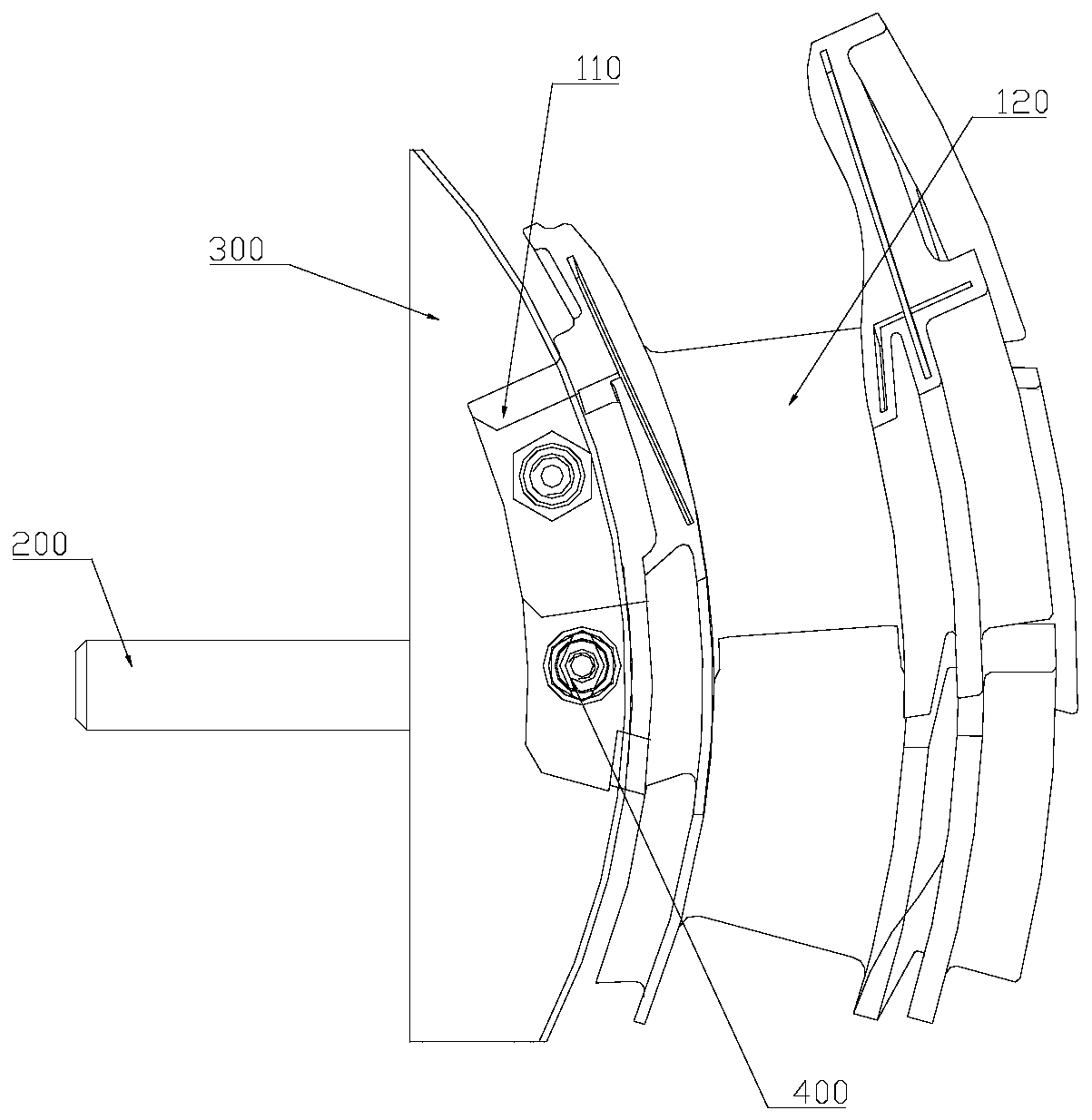

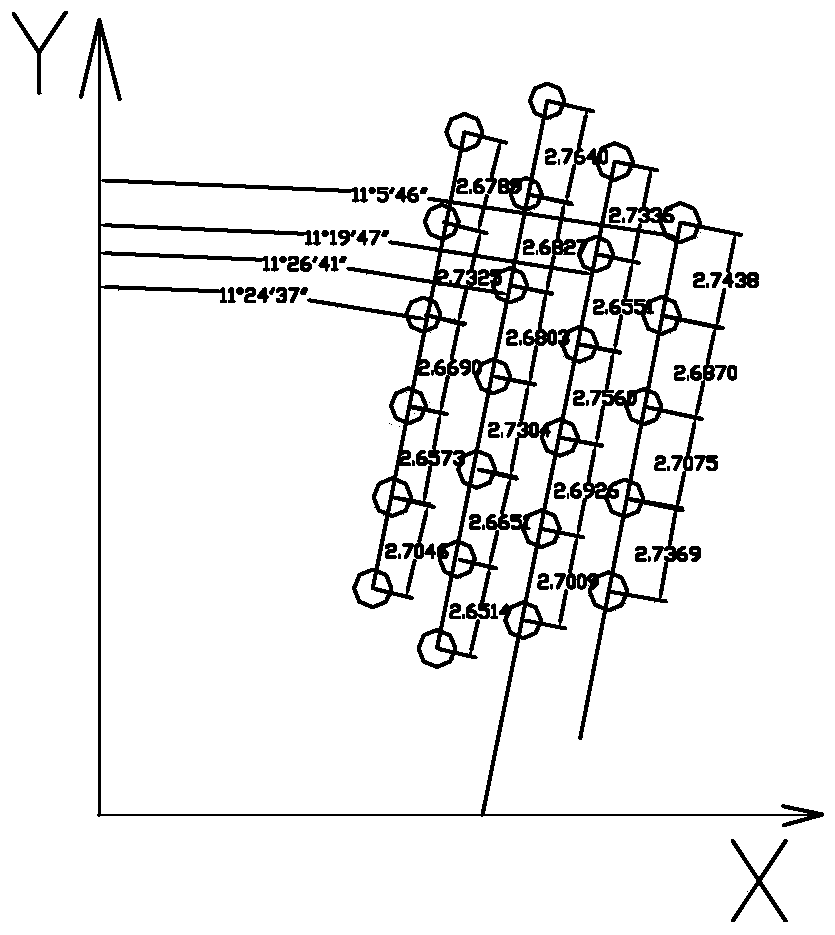

[0026] In order to find the stacking axis of the gas turbine blade and establish the blade detection coordinate system, the present invention also provides an auxiliary fixture for the composite optical coordinate machine measurement method of the first-stage guide blade of the gas turbine, such as figure 1 As shown, the clamp includes a handle 200 and a support plate 300 fixedly connected to one end of the handle 200 . Mounting holes are provided on the support plate 300, and the number of the mounting holes can be adjusted according to the number of blades to be mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com