Rapid responding miniature capacitance type humidity-sensitive element with porous upper electrode and parallel board electrode

A technology of parallel plate capacitance and fast response, which is applied in the direction of material capacitance, etc., can solve the problems of long diffusion path of water vapor molecules, and the effect of response time of humidity sensor is not obvious, and achieve the effect of improving response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to specific embodiments.

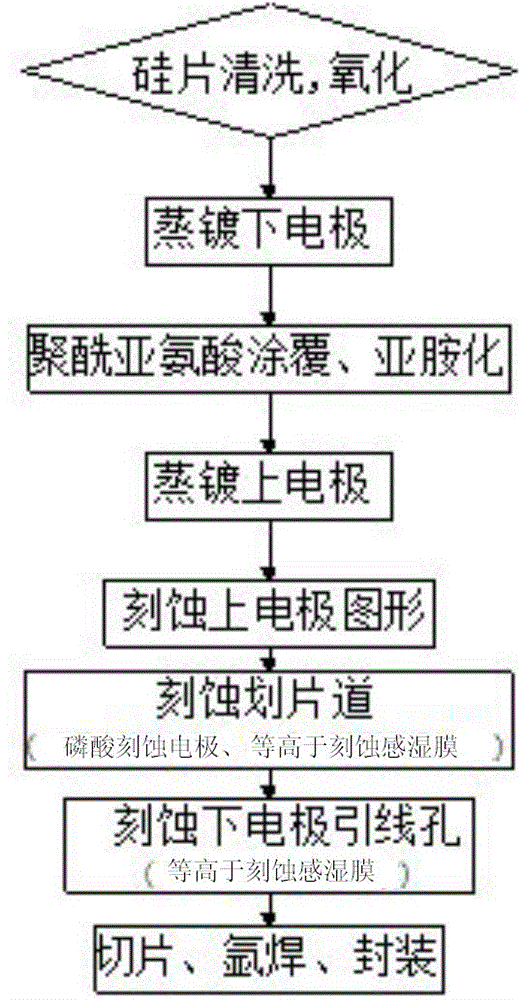

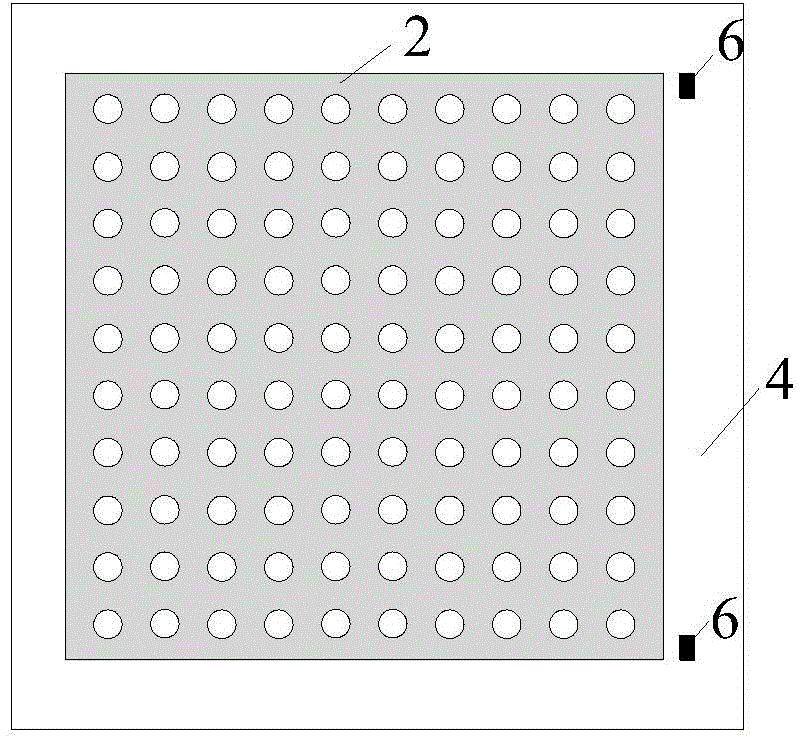

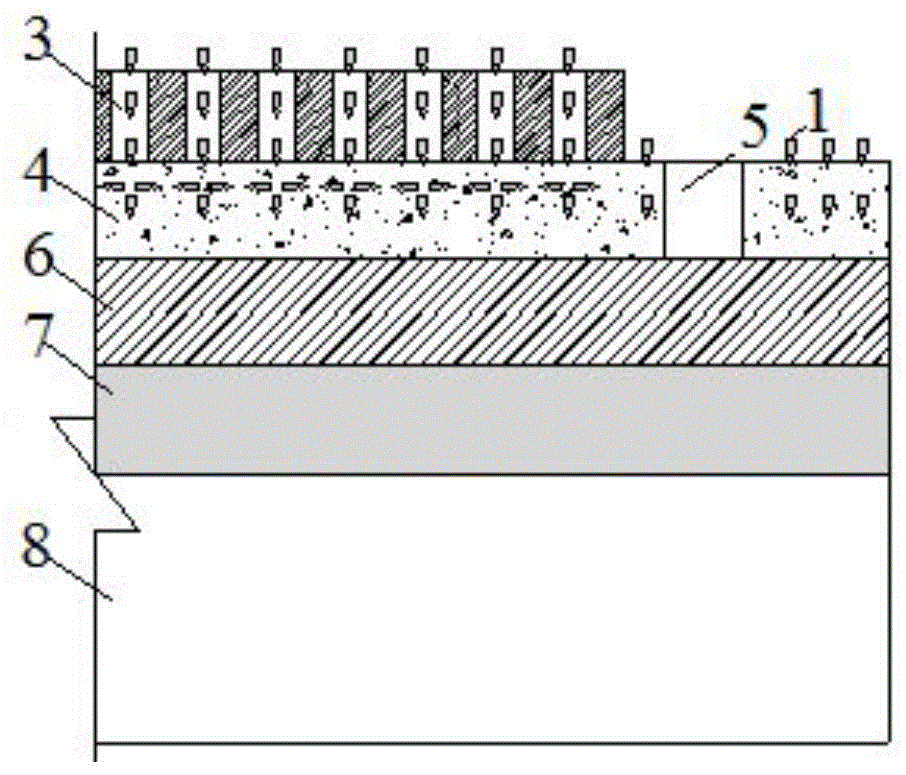

[0018] The porous upper electrode parallel plate capacitive humidity sensor of the present invention is as follows: figure 1 and figure 2 As shown, from top to bottom are the hole-shaped upper electrode 2, the PI moisture-sensing film 4, the flat lower electrode 6, the SiO 2 The insulating layer 7 and the Si substrate 8, the Si substrate 8 can be selected from silicon wafers, the upper electrode 2 and the lower electrode 6 are Mo-Al electrodes, wherein the hole-shaped upper electrode 2 is provided with a number of neatly arranged upper electrode holes 3, and the upper electrode holes The aperture of 3 is preferably 2 μm, and the minimum distance between the centers of the upper electrode holes 3 is preferably 4 μm. The lower electrode lead hole 5 formed by etching the PI moisture-sensitive film 4 is used for argon welding of the lower electrode lead. In the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com