Kettle type reactor

A tank reactor and reactor technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, feeding devices, etc., can solve the problem of low reaction efficiency and unstable product quality in tank reactors , long production time and other issues, to achieve the effect of good product quality stability, convenient implementation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

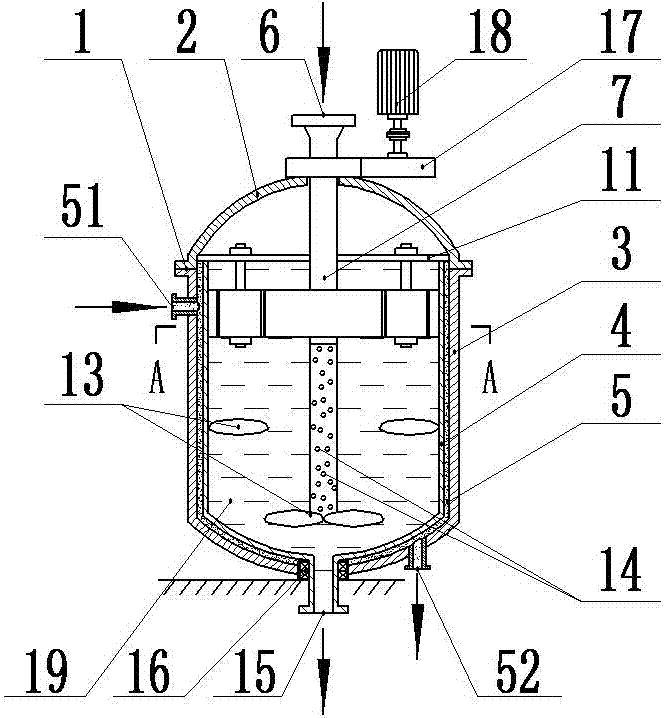

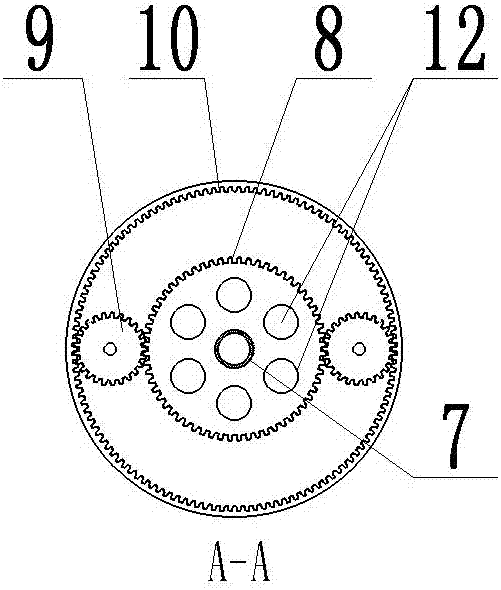

[0036] Such as figure 1 Shown, a kind of tank reactor, it comprises reactor body 1, temperature regulation mechanism and drive mechanism; Temperature regulation mechanism is arranged on the periphery of reactor body 1, and reactor body 1 is connected with drive mechanism; A material inlet 6 and a material outlet 15 are provided; the reactor body 1 includes an upper casing 2 and a lower casing 3; the upper casing 2 is sealed with the lower casing 3; There is an inner casing 4, and there is a certain gap between the lower casing 3 and the inner casing 4; the inner casing 4 is also provided with a stirring mechanism. The temperature regulating device includes a temperature regulating gap 5, a gas-liquid inlet 51 and a gas-liquid outlet 52; the temperature regulating gap 5 is located between the lower casing 3 and the inner casing 4; the gas-liquid inlet 51 and the gas-liquid outlet 52 are both Through the lower casing 3 to the temperature adjustment gap 5; the gas-liquid inlet 5...

Embodiment 2

[0041] Based on the tank reactor of embodiment 1, a kind of preparation method of corrosion-resistant coating is:

[0042] a, 12 parts of titanium dioxide, 6 parts of boron carbide, 14 parts of novolak epoxy resin, 18 parts of epoxy resin and 50 parts of rare earth yttrium sol are stirred in the mixer for 15-20min in proportion, and the stirring speed is 1000r / min;

[0043] b. Repeatedly spray the coating obtained in step a on the corresponding position of the parts that need the corrosion-resistant coating to form a uniform coating;

[0044] c. Send the parts coated with paint in step b into a drying oven for heating and drying, the temperature is 300 ° C, and the drying time is 1-2 hours;

[0045] d. Heat the dried parts in a resistance furnace, control the temperature at 400°C-600°C, and keep the heat for 3-5 hours;

[0046] e. After the furnace cools down, just take it out of the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com