Non-contact composite material frequency domain dielectric spectroscopy measurement method

A technology of frequency-domain dielectric spectrum and composite materials, which is applied in the field of non-contact measurement of frequency-domain dielectric spectrum of composite materials, can solve the problems of affecting the dielectric properties of materials, high gold cost, and easily intrusive materials, and achieve accurate planning characteristics , avoid material deformation, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

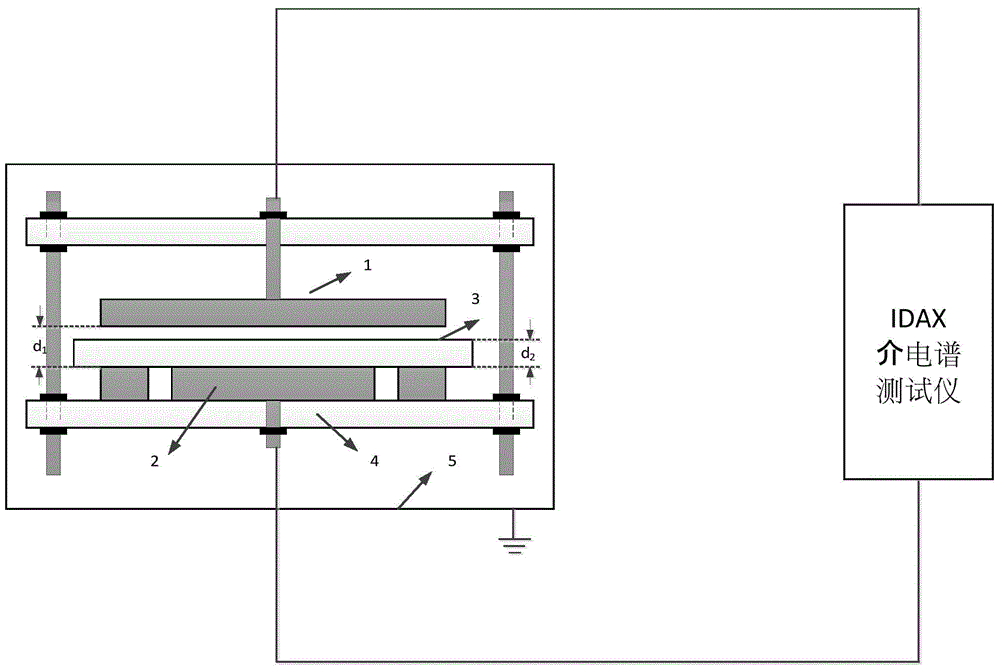

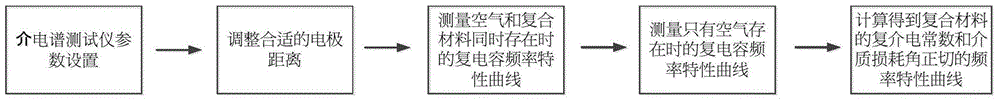

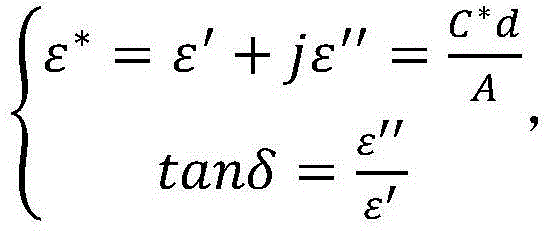

[0033] Such as figure 1 As shown, the present invention proposes a non-contact method for measuring the frequency-domain dielectric spectrum of composite materials, using air dielectric spectrum as a reference calibration, and combining the series model of air and composite materials to measure the frequency dielectric spectrum of composite materials. Such as figure 2 Shown, what the present invention adopted is IDAX-300 dielectric spectrum test system, and described test process comprises the steps:

[0034] 1. Input the test voltage, frequency range, frequency interval and other parameters on the dielectric spectrum tester through the preset software as required.

[0035] 2. Fix the lower electrode 2 on the bracket 4 .

[0036] 3. The composite material 3 (the thickness of the composite material is d 2 , the area of the composite material is a 1 ) placed between the test electrodes. The required area of the test piece a 2 Greater than the electrode area a 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com