Calibration device and method of ultra-high frequency partial discharge sensor

A partial discharge and calibration device technology, which is applied to measurement devices, instruments, measuring electrical variables, etc., can solve the problems of cumbersome process, aliasing of different spectrums, and difficult evaluation of calibration results, achieve accurate bandwidth and sensitivity, and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

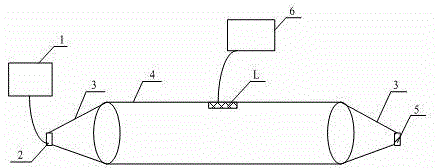

[0028] Such as figure 1 As shown, in the embodiment of the present invention, a calibration device for an ultra-high frequency partial discharge sensor is proposed, which cooperates with the ultra-high frequency partial discharge sensor L to be calibrated, and the device includes a signal generator for providing an ultra-high frequency signal 1. Signal receiver for receiving UHF signals 2. Impedance transition section for eliminating refraction and reflection of UHF signals 3. Coaxial transmission line for generating TEM waves during UHF signal transmission 4. Matching Impedance 5 and an oscilloscope 6 for displaying TEM wave frequency and amplitude; wherein,

[0029] There are two impedance transition sections 3, and the two impedance transition sections 3 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com