SOP element positioning and defect detecting method based on vision

A defect detection and component technology, applied in image data processing, instruments, calculations, etc., can solve problems such as insufficient precision and sensitivity to changes in the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

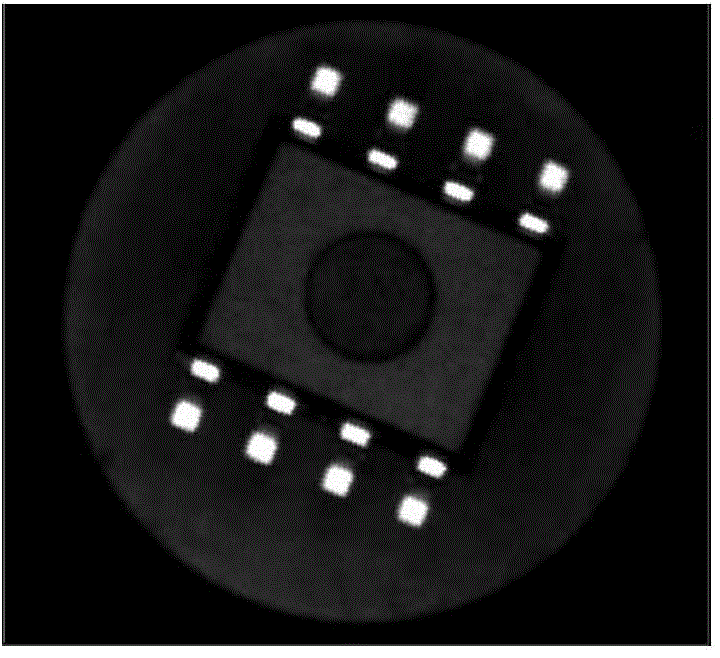

[0052] Specific embodiment one: a kind of vision-based SOP component location and defect detection method of the present embodiment, it realizes according to the following steps:

[0053] 1. Check whether the image in the selected area meets the brightness requirements;

[0054] (1) Scan all the image pixels in the selected area, and record the total number of image pixels as s 1 , the number of pixels whose gray value is greater than 150 is recorded as s 2 ;

[0055] (2) Take the ratio r 1 =0.03, r 2 =0.90, if s 1 / s 2 1 image area is too dark, if s 1 / s 2 >r 2 If the image area is too bright, stop and return the corresponding error code; otherwise, continue to the next step;

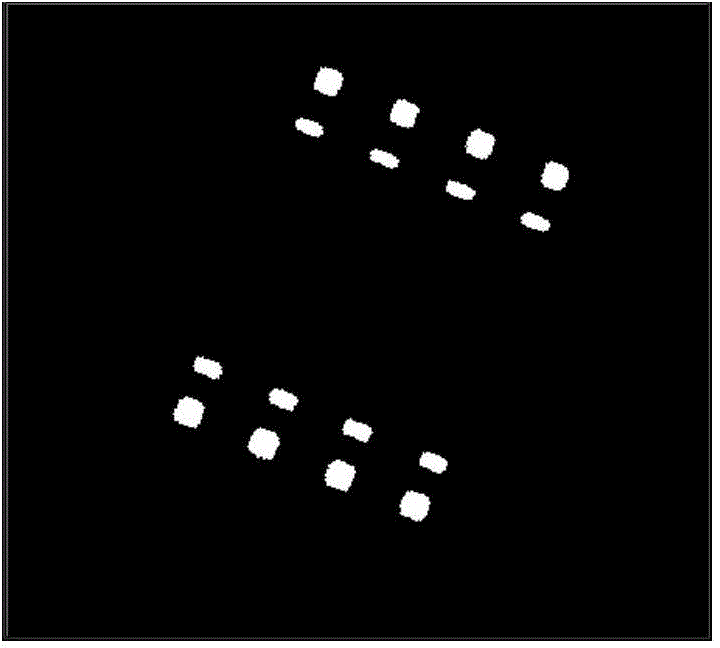

[0056] 2. Binarize the image of the selected area to obtain a binarized image;

[0057] The second step is specifically:

[0058] (1) The first method is to manually input a fixed threshold value binarization method, that is, the input threshold value is T, when the pixel value t of the i-th...

specific Embodiment approach 2

[0082] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: the step four is specifically:

[0083] The main purpose is to deal with the following two types of outer boundary point sets: one is due to the redundant outer boundary point sets generated when the threshold selection of the second step binarization process is too low, it is necessary to remove such outer boundary point sets; the other is due to There are internal and nested relationships between some boundaries, and the relationship between such outer boundary point sets needs to be clarified;

[0084] 1) Take the outer boundary point set of a certain binarized image obtained in the third step, and require that the number of points contained in it must be greater than 10, otherwise directly remove the outer boundary point set;

[0085] 2) Check whether each outer boundary point set of the binarized image has an inner or nested outer boundary point ...

specific Embodiment approach 3

[0090] Specific implementation mode three: the difference between this implementation mode and specific implementation modes one or two is that the step five is specifically:

[0091] Use the bubble sorting method to sort each boundary point set in the fourth step according to the size of the area surrounded by the boundary from small to large;

[0092] 1) Calculate the average value of the area of the three boundary point sets in the middle and denote it as a;

[0093] 2) In turn, the area a surrounded by each boundary point set i Compare with a, keep a i i >0.6*a boundary point set i; where, the a i is the area of the i-th boundary point set.

[0094] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com