Sprayer motion control system based on FPGA and motion control method thereof

A technology of motion control system and motion controller, which is applied in the motion control system of spraying machine and the field of motion control of spraying machine based on FPGA, can solve the problems of slow speed, poor real-time performance, and insufficient processing precision, and achieve fast response and real-time performance Good, high-precision processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

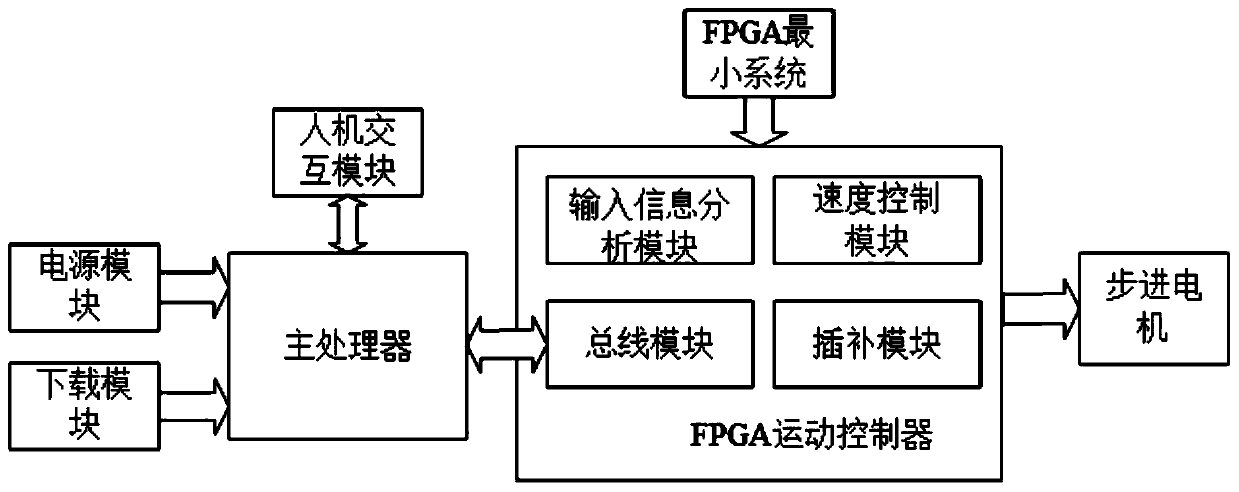

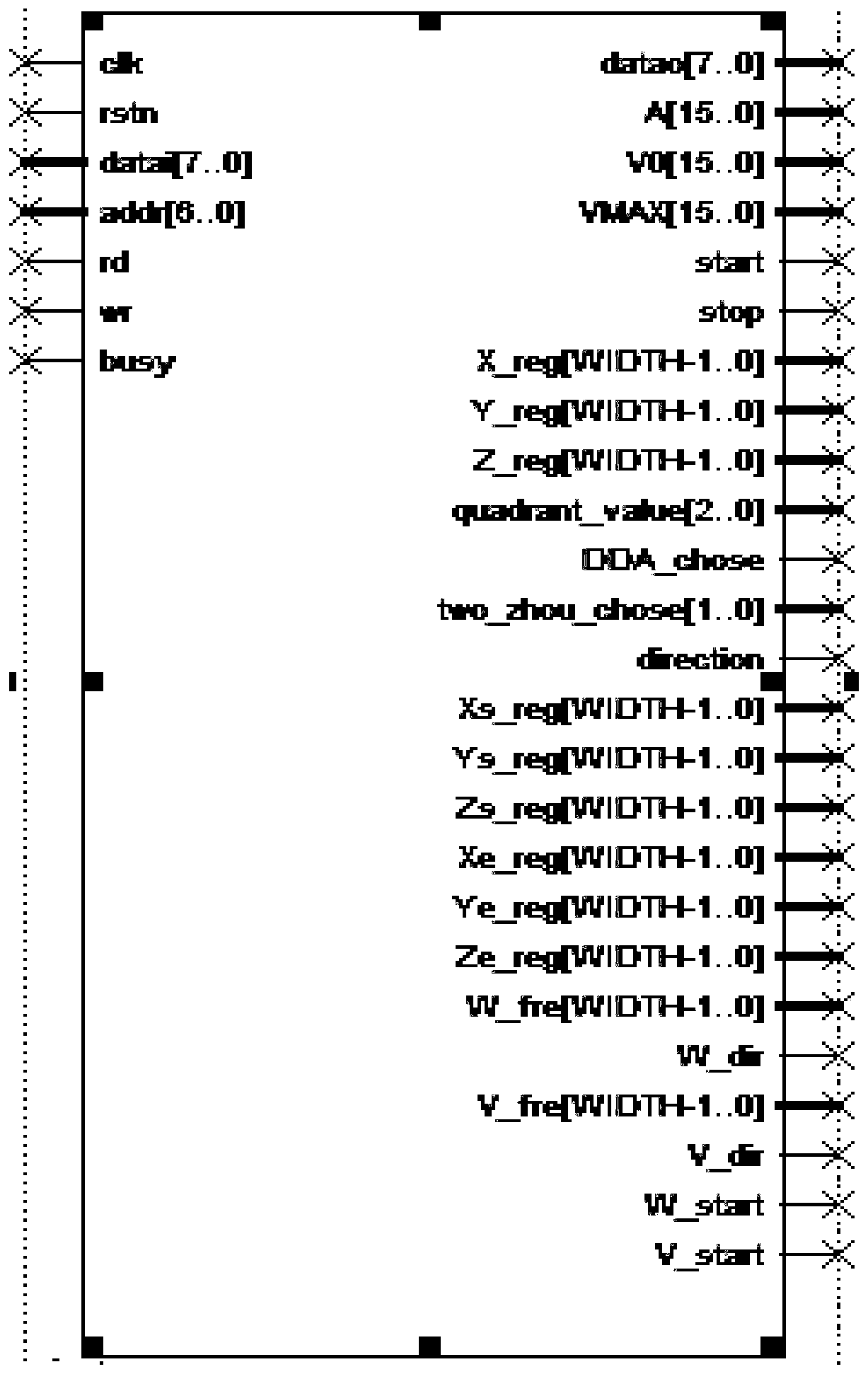

[0077] see figure 1 , the present embodiment provides a sprayer motion control system based on FPGA, which is used to control the five-axis automatic sprayer, and can realize speed control and trajectory interpolation. Among them, the five-axis automatic spraying machine includes a control fixture, a spray gun, three linear axis stepping motors and two rotary axis stepping motors, and the three linear axis stepping motors respectively drive the spray gun to move linearly in three-dimensional directions. The stepper motor drives and controls the rotation of the fixture and the spray gun respectively. The FPGA-based spraying machine motion control system includes a main processor, a motion controller, and peripheral circuits. The motion controller receives the motion information sent by the main processor and controls the five-axis automatic spraying machine according to the motion information. The motion controller includes an input information analysis module, a speed control...

Embodiment 2

[0163] The present embodiment provides a kind of spraying machine motion control method based on FPGA, and this method is applied in the spraying machine motion control system based on FPGA in embodiment 1, and it comprises the following steps:

[0164] Decode the motion information, and obtain the initial speed, given feed speed, fixed value acceleration and feed distance of the spray gun in the three-dimensional direction, and also obtain the initial coordinate value and end point of the spray gun in the three-dimensional direction Coordinate value and displacement, and control the rotation direction and rotation frequency of fixture and spray gun; Wherein, this step can adopt the input information analysis module of embodiment 1 to realize;

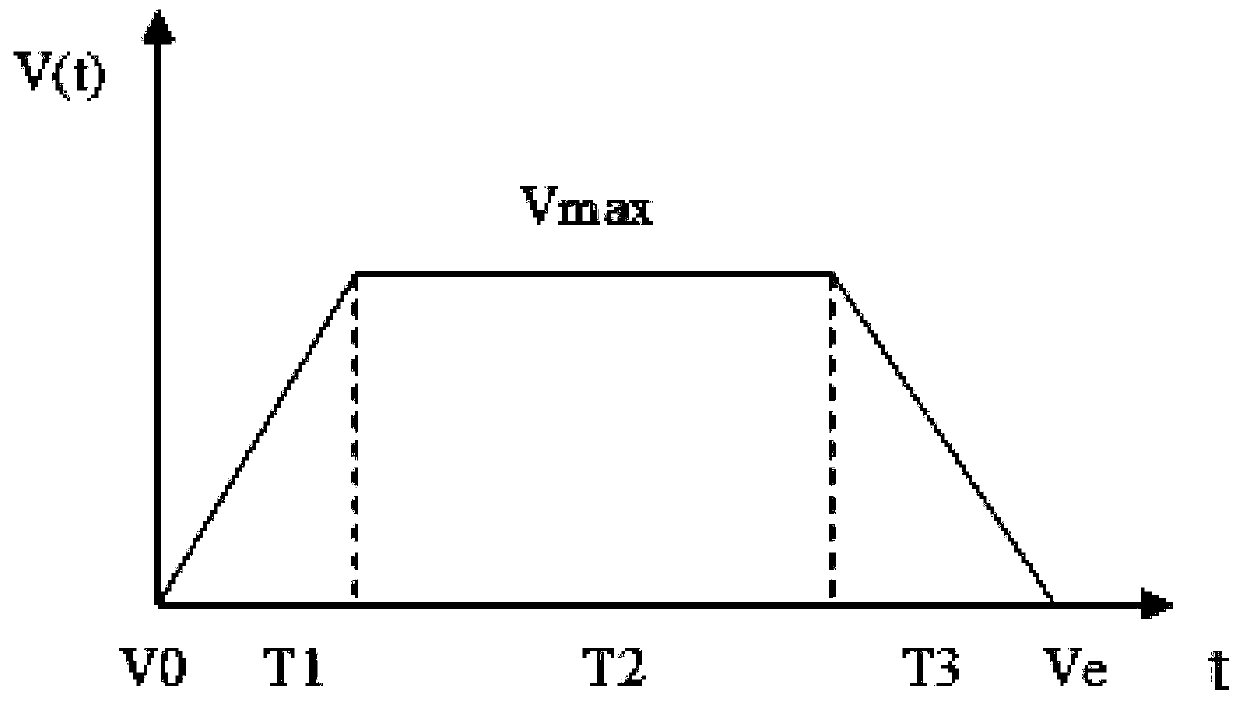

[0165] According to the initial speed, given feed speed, fixed value acceleration and feed distance, calculate the travel distance and travel time of each axis of the spray gun in the acceleration phase, constant speed phase and deceler...

Embodiment 3

[0168] This embodiment provides a spraying system based on FPGA, which includes a five-axis automatic spraying machine and a motion control system. Among them, the motion control system is used to control the five-axis automatic spraying machine, and the five-axis automatic spraying machine includes control fixtures, spray guns, three linear axis stepping motors and two rotary axis stepping motors, and the three linear axis stepping motors are respectively The spray gun is driven to move linearly along the three-dimensional direction, and the two rotary axis stepper motors drive and control the rotation of the fixture and the spray gun respectively. The motion control system adopts the FPGA-based spraying machine motion control system in Embodiment 1, and the use effect of the FPGA-based spraying system of this embodiment is the same as that of the motion control system in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com