An Improved Deviation Coupling Control Method for Multi-motor Systems

A technology of deviation coupling and control method, applied in the direction of speed adjustment of multiple motors, can solve the problems of inability to adjust the synchronization performance and tracking performance separately, large synchronization error, differentiation, etc., to reduce the portability of the algorithm, improve the degree of freedom, The effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

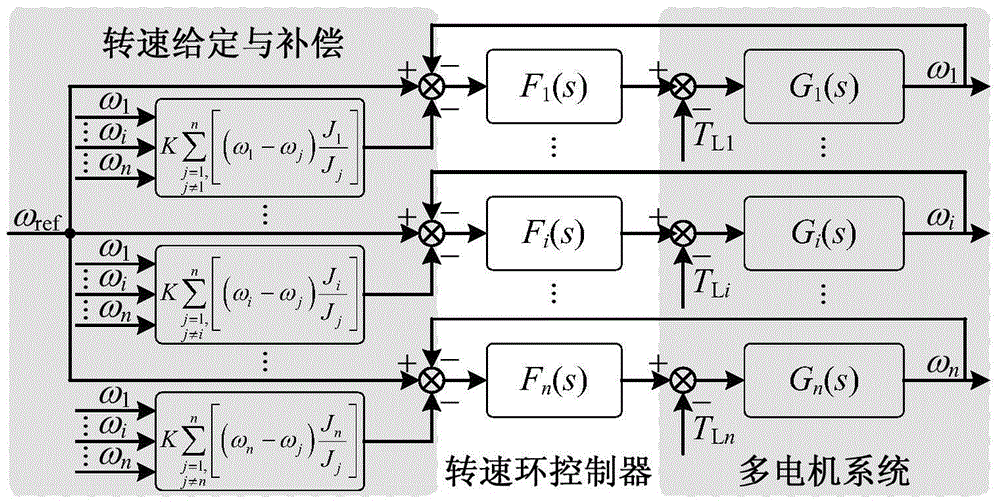

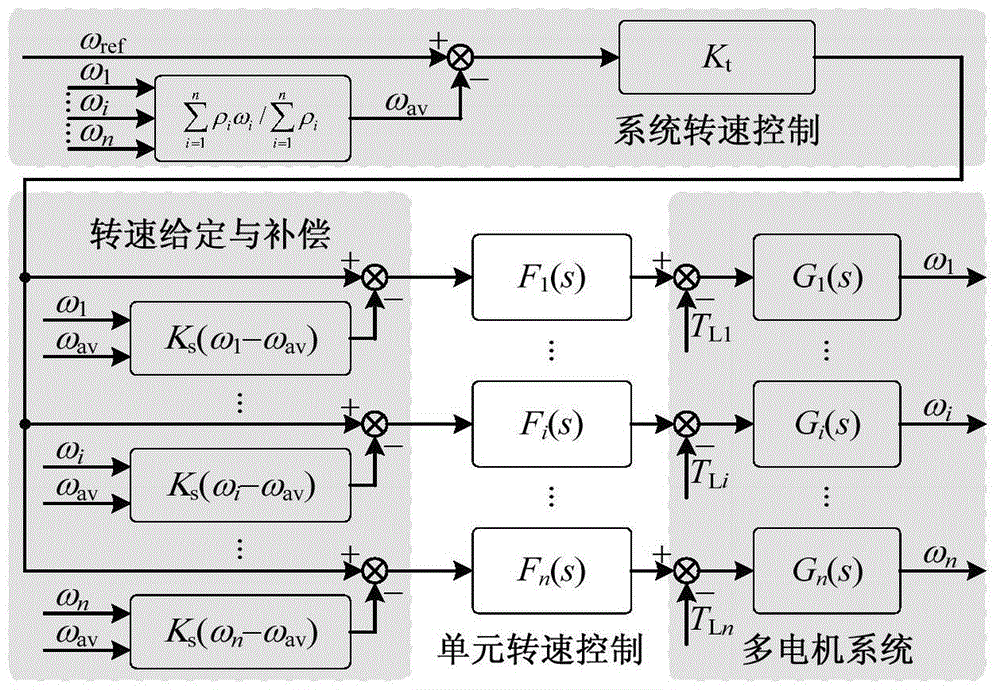

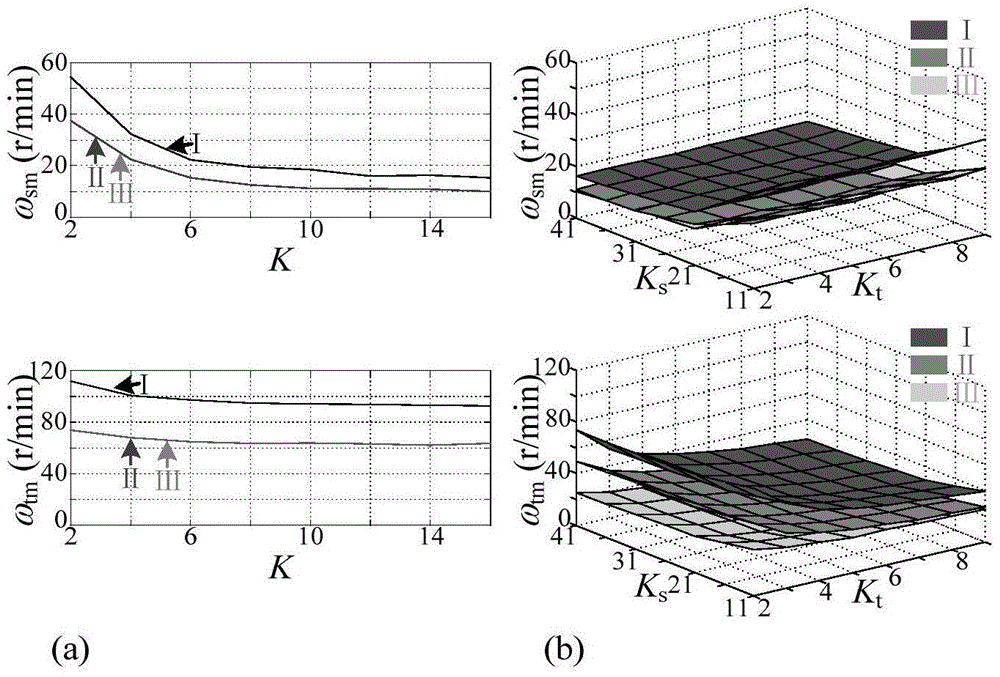

[0032]The purpose of the present invention is to solve the problems existing in the traditional deviation coupling control structure that the importance of each motor speed in the system is not considered and the synchronous performance and tracking performance of the system cannot be decoupled and adjusted, and an improved deviation coupling control structure is proposed. The structure reflects the importance of the speed of each motor in the system through the speed weight coefficient, and can decouple the synchronization performance and tracking performance of the system by adjusting the synchronization coefficient and tracking coefficient in the structure. At the same time, the structure can effectively improve the synchronization performance and tracking performance of the system under the premise of applying a proportional-integral control strategy (PI control strategy), that is, without greatly increasing the calculation amount of the processor.

[0033] In order to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com