Fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell recycling, etc., can solve the problems of cost-intensive, perfluorinated membrane consumption, etc., to achieve increased structural volume, rapid cooling Effects on start performance or cold start performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

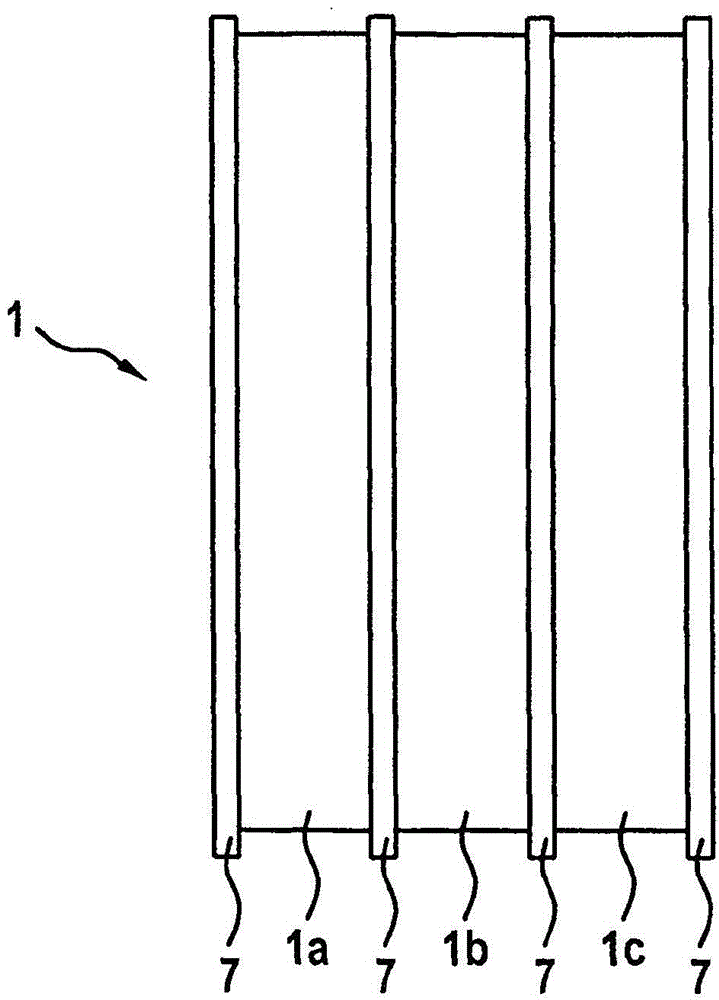

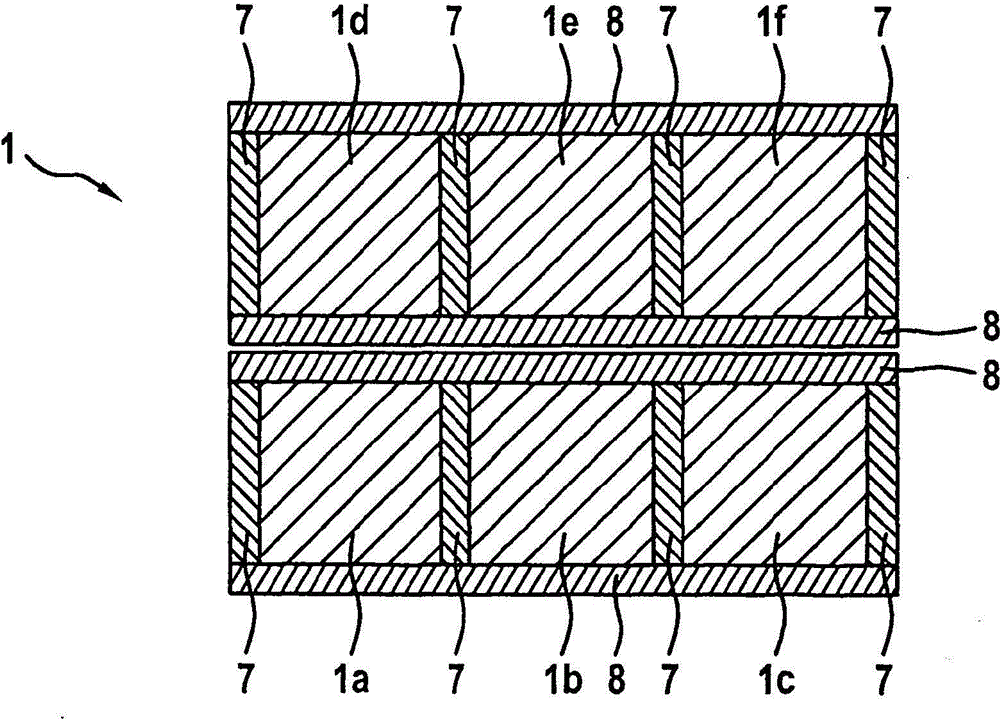

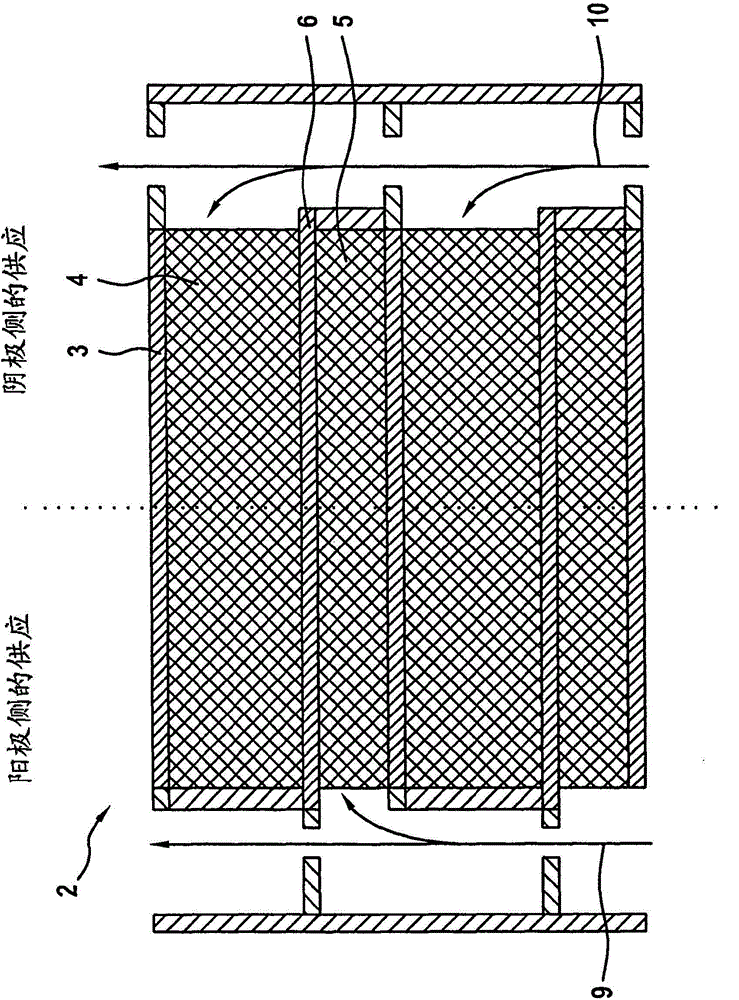

[0024] Only the components of the fuel cell system that are relevant here are shown in the figures, all other elements have been omitted for the sake of clarity.

[0025] Figures 1 to 3 A fuel cell system 1 according to the invention is shown which has a plurality of substantially rectangular or square individual fuel cells 2 each organized into a stack 1a-1f. The individual fuel cells 2 each comprise an essentially planar membrane electrode unit 3, two gas diffusion layers 4, 5 in the form of fibers adjoining the opposite larger surfaces of the membrane electrode unit 3, and a bipolar plate 6. The bipolar plate establishes an electrical connection with the adjacent single fuel cell 2 located above or below it, including the active area surrounded by the edge area.

[0026] The bipolar plate 6 is completely planar in the active region, so that only the gas-conducting region is formed by the gas diffusion layers 4 , 5 , which accounts for at least 60% of the height of the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com