Preparation method for ball bursting beverage

A manufacturing method and beverage technology, applied in the field of beverage manufacturing, can solve the problem of low density of the outer wall of beads and achieve the effect of increasing fun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare the first beverage: by calcium lactate 3wt%, syrup 7wt%, concentrated fruit juice 10wt%, xanthan gum 0.3wt%, carboxymethyl cellulose 0.3wt%, konjac powder 0.02wt%, malic acid 0.15wt%, citric acid 0.5wt%, and the balance is water to make a solution.

[0017] Preparation of sodium alginate solution: 1.5wt% sodium alginate, 0.03wt% gelatin, and water as the balance.

[0018] Drop the first beverage into the sodium alginate solution drop by drop from the dropper to form beads. When the concentration of sodium alginate is less than 1wt%, add sodium alginate to maintain the concentration of 1-3wt%. Similarly, when the concentration of gelatin When it is less than 0.01-0.3 wt%, add gelatin to maintain the concentration of 0.01-0.3 wt%. The generated beads were filtered out, immersed in an aqueous solution containing 0.5wt% polyacrylic acid and 0.12wt% chitosan to react for 0.5 hours, and then washed with water. Mix the beads into a second drink to create a bead pop d...

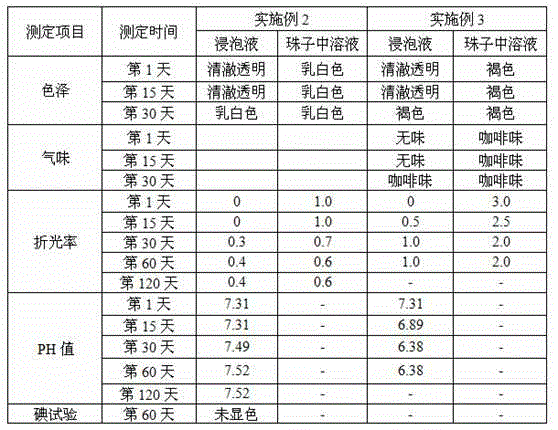

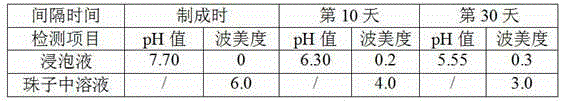

Embodiment 2

[0024] Prepare the first beverage: 1% tapioca starch, 5wt% calcium lactate, 0.3wt% xanthan gum, 0.1wt% carboxymethyl cellulose, and the balance is water to form a solution.

[0025] Preparation of sodium alginate solution: 2.2wt% sodium alginate, 0.3wt% gelatin, and water as the balance.

[0026] Gradually drop the first beverage into the sodium alginate solution from the dropper to form beads, add sodium alginate to maintain the concentration of 1-3wt% when the concentration of sodium alginate is less than 1wt%, similarly, when the concentration of gelatin is less than 0.01-0.3wt% %, add gelatin to maintain a concentration of 0.01—0.3 wt%. The generated beads were filtered out, immersed in an aqueous solution of 0.3wt% polyacrylic acid and 0.1wt% chitosan to react for 0.5 hours, and then washed with water. Mix the beads into a second drink to create a bead pop drink.

Embodiment 3

[0028] Prepare the first beverage: 5wt% coffee powder, 2wt% calcium lactate, 0.3wt% xanthan gum, 0.1wt% carboxymethyl cellulose, and the balance is water to form a solution.

[0029] Preparation of sodium alginate solution: 2.2wt% sodium alginate, 0.3wt% gelatin, and water as the balance.

[0030] Gradually drop the first beverage into the sodium alginate solution from the dropper to form beads, add sodium alginate to maintain the concentration of 1-3wt% when the concentration of sodium alginate is less than 1wt%, similarly, when the concentration of gelatin is less than 0.01-0.3wt% %, add gelatin to maintain a concentration of 0.01—0.3 wt%. The generated beads were filtered out, immersed in an aqueous solution of 0.8wt% polyacrylic acid and 0.1wt% chitosan to react for 0.5 hours, and then washed with water. Mix the beads into a second drink to create a bead pop drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com