Method for rapidly drying fresh whole angelica roots

A technology of rapid drying and drying method, which can be used in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., and can solve the problems of low drying efficiency, long drying time, and unsuitable for industrial large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

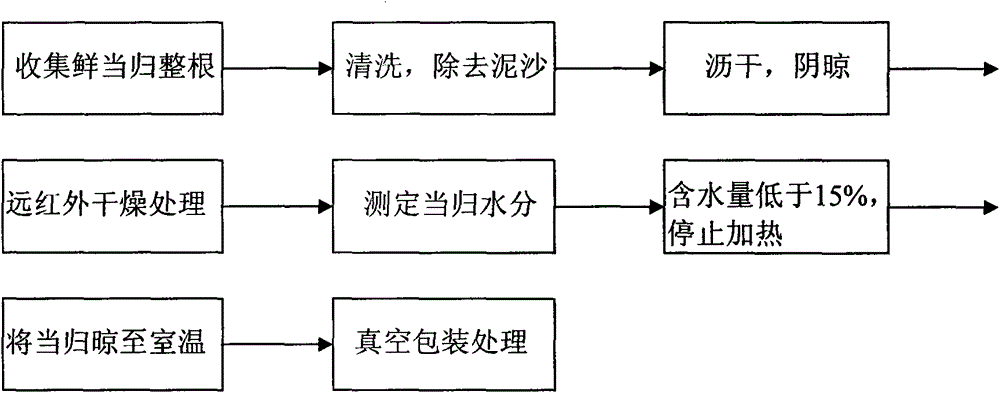

Method used

Image

Examples

example 1

[0024] Example 1: Collect fresh whole root of Angelica sinensis, randomly select a total of 5kg in different sizes, gently remove the silt on the surface of Angelica sinensis with a brush, avoid damaging the skin of Angelica sinensis, drain the water, place Angelica sinensis in a far-infrared drying equipment, power After heating at 1000W for 3 hours, the whole root of Angelica sinensis was left to cool at room temperature and vacuum packed.

example 2

[0025] Example 2: Collect fresh whole Angelica sinensis, randomly select a total of 5kg in size, use a brush to gently remove the silt on the surface of Angelica sinensis, avoid damaging the skin of Angelica sinensis, drain the water, place Angelica sinensis in a far-infrared drying equipment, power After heating at 2000W for 2 hours, the whole root of Angelica sinensis was left to cool at room temperature and vacuum packed.

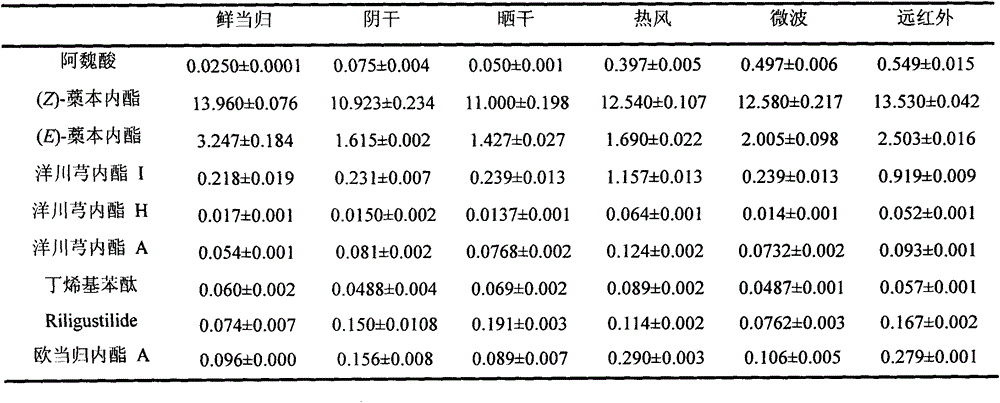

[0026] The results showed that the drying time of this method was significantly shortened, the efficiency was high, and the preservation requirements of Angelica sinensis could be met, and the content of active ingredients remained high.

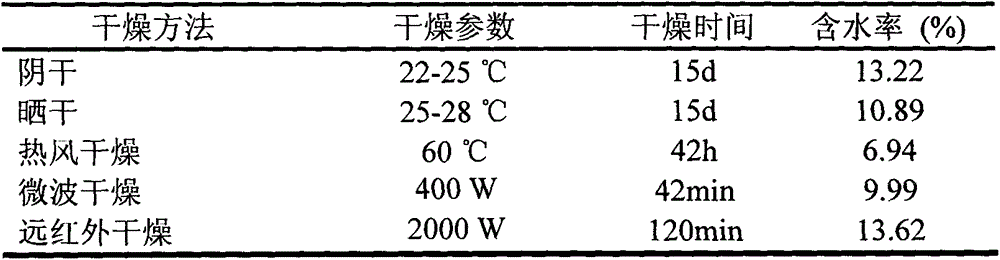

[0027] Table 3 Content and Moisture Determination Results (mg / g)

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com