Method for improving density of fast bed and reactor

A bed reactor, high-density technology, applied in the fields of olefin production, aromatics production equipment, petrochemical industry, fluidization, can solve the problems of low catalyst density, small catalyst storage capacity, etc., to increase catalyst density, increase storage capacity, Improve conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

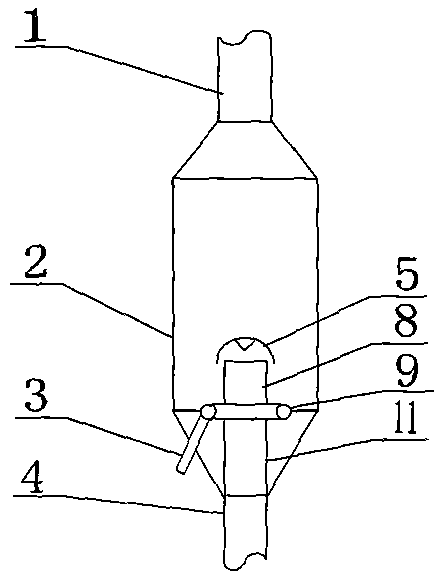

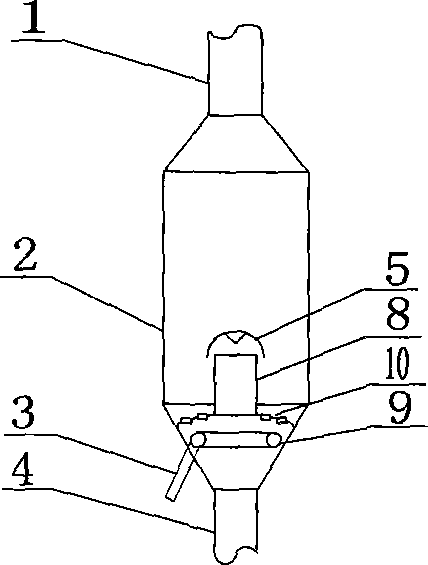

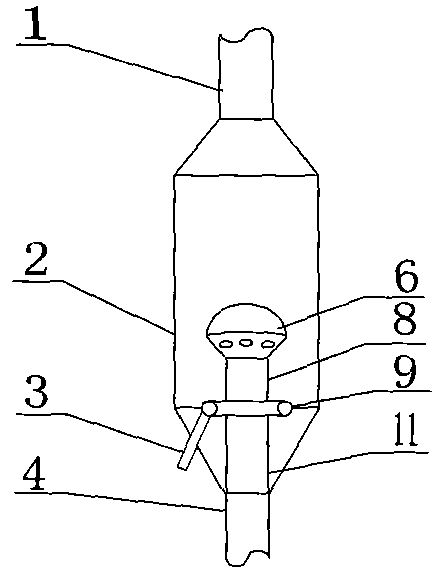

[0025] See Figure 1A ~ Figure 3B , the upper end of the fast bed reactor shell 2 is connected with the outlet pipe 1, and the lower end is connected with the process medium inlet pipe 4. Figure 1A , Figure 1B is an umbrella cap type reverse distributor 5, Figure 2A , Figure 2B is a mushroom type reverse distributor 6, Figure 3A It is a multi-tube (several straight tubes) reverse distributor 7A, Figure 3B Multi-tube type (several flat tube openings) reverse distributor 7B. Figure 1A , Figure 2A , Figure 3A The reverse distributors 5, 6, 7A are connected to the process medium inlet pipe 4 and the bottom of the fast bed reactor shell 2 through the feed pipe 8, and the gas feed distributor 9 is arranged at the lower part of the fast bed reactor shell 2 and connected with the gas Feed pipe 3 is connected. Figure 1B , Figure 2B , Figure 3B The reverse distributors 5, 6, 7B are connected to the distribution plate 10 through the feed pipe 8, the distribution plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com