Automatic sand screening device

A sand screener, automatic technology, applied in the direction of filtration, chemical instruments and methods, solid separation, etc., can solve the problems of bulky sand screener, cumbersome working process, affecting efficiency, etc., to save manpower, fully stir, replace low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

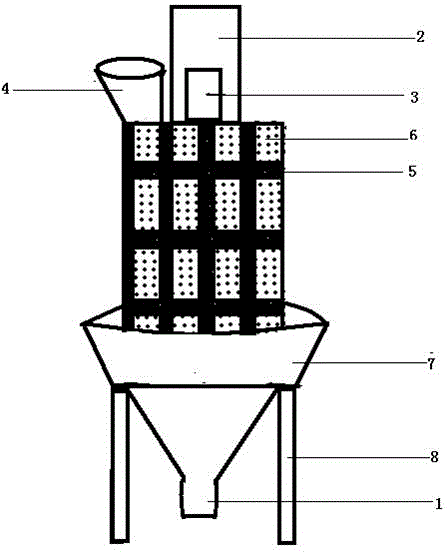

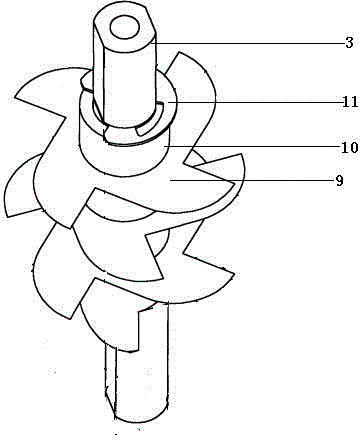

[0018] like figure 1 , figure 2 The technical scheme of the present invention shown is as follows: a kind of automatic sand screener is made up of support 1, motor 2, rotating turbine 3, feeding port 4, machine barrel 5, screen cloth 6, collection chamber 7, discharge port 8. The motor is connected to the rotating turbine 3, and the rotating turbine 3 is located inside the barrel 5. The barrel 5 is a hollow cylinder, and the outside is fixedly connected to the screen 6. One end of the barrel 5 is connected to the feeding port 8, and the collection chamber 7 is connected to the bracket 1. The end Set the outlet 8. In the described automatic sand screener, the rotating turbine 3 is a multi-stage turbine, which is composed of a shaft, a shaft sleeve 10, a fixing part 11 and a blade 9. In the described automatic sand screener, the collection chamber 7 is made of el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com