Full-automatic hot-pressing equipment for wood floor

A hot-pressing equipment and fully automatic technology, applied in veneer presses, plywood presses, wood processing appliances, etc., can solve the problems of slow efficiency, manual removal, waste of manpower, etc., to save human resources, move smoothly, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

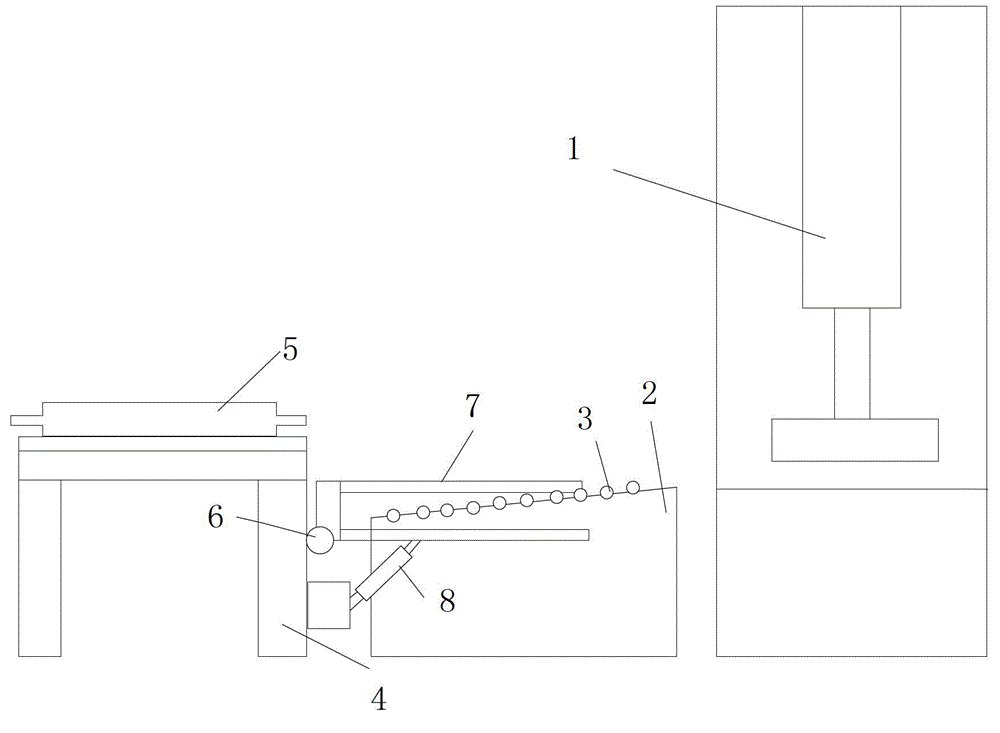

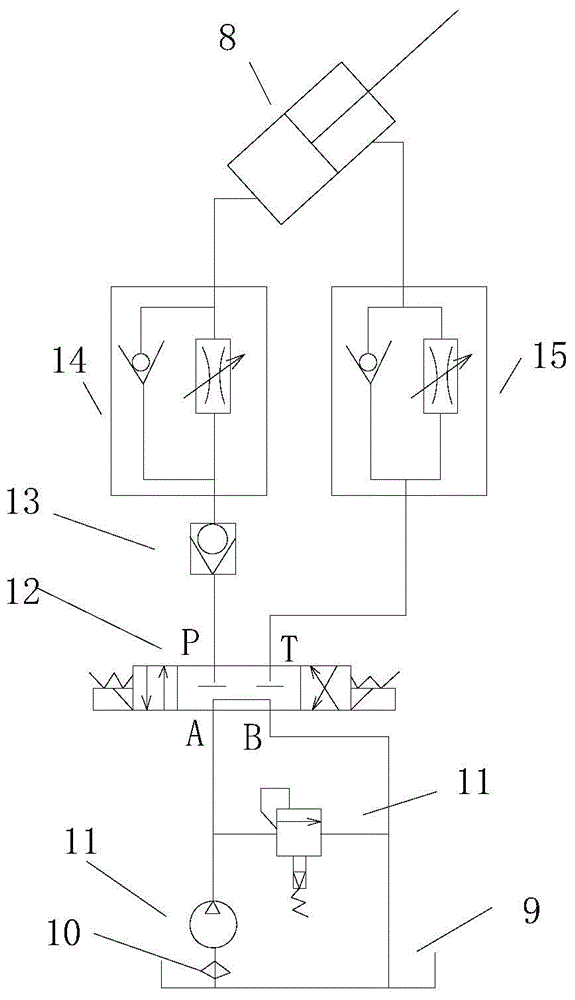

[0011] A fully automatic hot pressing equipment for wooden floor, as attached figure 1 And attached figure 2 As shown, it includes a mechanical mechanism and a hydraulic mechanism. The mechanical mechanism includes a press machine 1. A slide table 2 is provided on the front side of the press machine 1, and a slide roller 3 is provided on the table of the slide table 2; Transport platform 4 is arranged, and transportation platform 4 is provided with transport roller 5, and transportation platform 4 is provided with rotating shaft 6, and rotating shaft 6 is provided with floor clamp 7, and the bottom of floor clamp 7 is provided with throwing off cylinder 8, and throwing off cylinder The bottom of 8 is fixed on the transport platform 4; the hydraulic mechanism includes a fuel tank 9, the fuel tank 9 is connected with a filter 10, the filter 10 is connected with a quantitative pump 11, and the quantitative pump 11 is connected with a three-position four-way reversing valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com