Small concrete mixing plant and concrete mixing method

A mixing method and concrete technology, which are applied in mixing plants, cement mixing devices, chemical instruments and methods, etc., can solve the problems of uneven mixing of concrete, difficulty in continuous and uninterrupted production, and large water discharge time, so as to reduce concrete condensation and reduce Risk and waste, the effect of increasing the level of agitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, the present invention is further described:

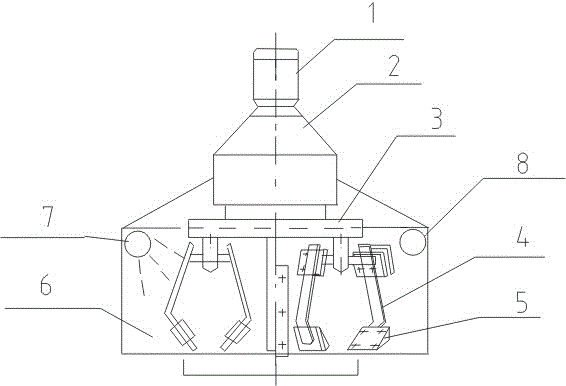

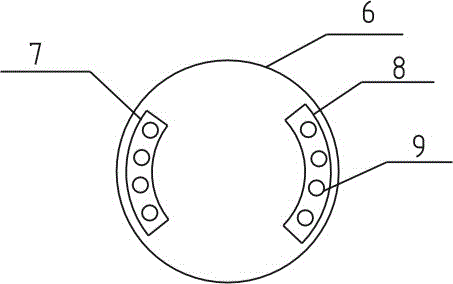

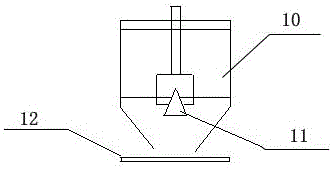

[0027] Such as figure 1 figure 2 image 3 The small concrete mixing plant shown includes a storage bin 10 in the feeding system, a partition belt 11 and a flat belt 12 at the lower part of the storage bin 10, and a mixing drum 6 above which a motor 1 and a reducer 2 are installed. The reducer 2 is connected to the rotary body 3 and extends into the mixing drum 6. A plurality of stirring arms 4 are installed at the bottom of the rotary body 3. Blades 5 are installed on the stirring arms 4. The mixing drum 6 is provided with a water outlet device, which includes There are water outlet holes 9 and thick water pipes 7 and thin water pipes 8 connected thereto. The thick water pipes 7 and thin water pipes 8 are respectively installed on both sides of the mixing drum 6 and are jointly connected to the centrifugal water pump, wherein the mouth of the thin water pipe 8 Facing the sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com