Roller belt conveyor

A technology of belt conveyors and conveyors, which is applied in the direction of conveyors, conveyor objects, rollers, etc., and can solve the problems that idler bearings are not easy to be explosion-proof, and cannot be adjusted to transport bulk grain and bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

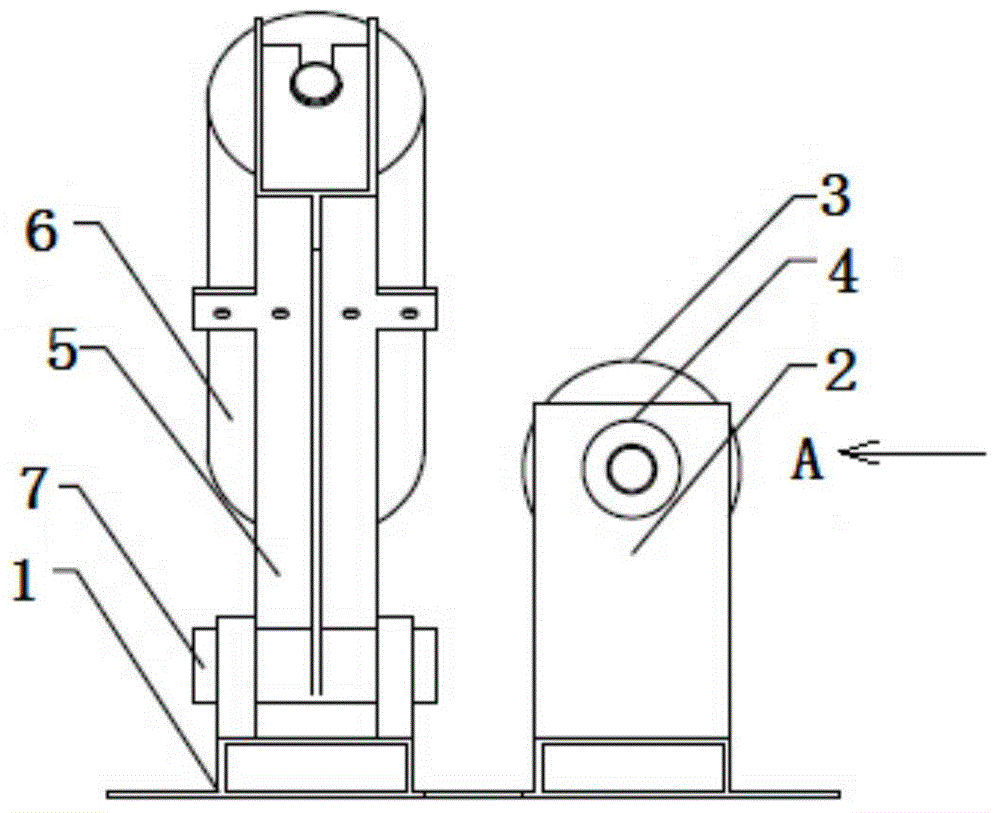

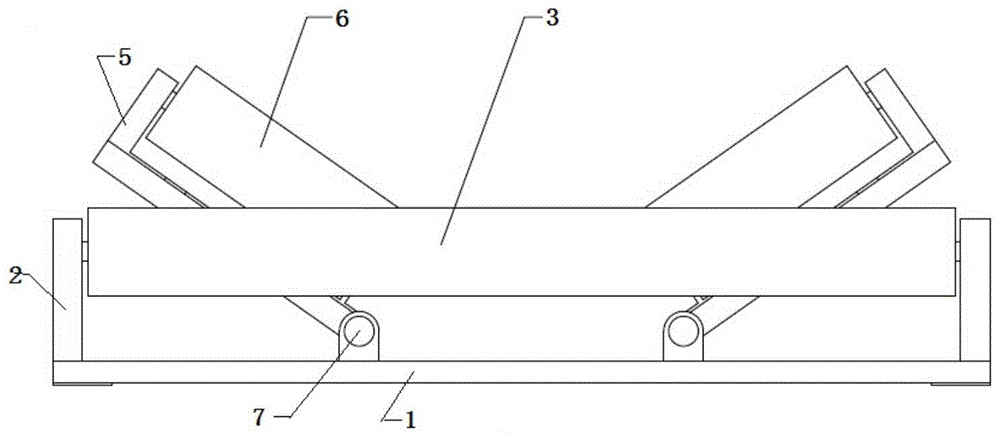

[0032]Roller belt conveyor includes: intermediate frame, outriggers, drive roller, drive roller drive, upper idler assembly, redirection pulley, return idler assembly, ball screw drive, and conveyor belt, and the outriggers are fixedly supported in the middle Below the frame, the front end of the middle frame is provided with a drive roller, which is connected to the drive roller drive device for driving the drive roller to rotate, and the end of the middle frame is equipped with a reversing roller, and the bottom of the middle frame is fixedly installed with a ball screw transmission device and The return idler assembly, the upper idler assembly is installed above, and the conveyor belt is sequentially bypassed by the drive roller, the upper idler assembly, the redirecting roller, and the return idler assembly, and then stitched end to end; wherein, the upper idler assembly includes: A horizontal idler with an explosion-proof device for idler bearings and an adjacently install...

Embodiment 2

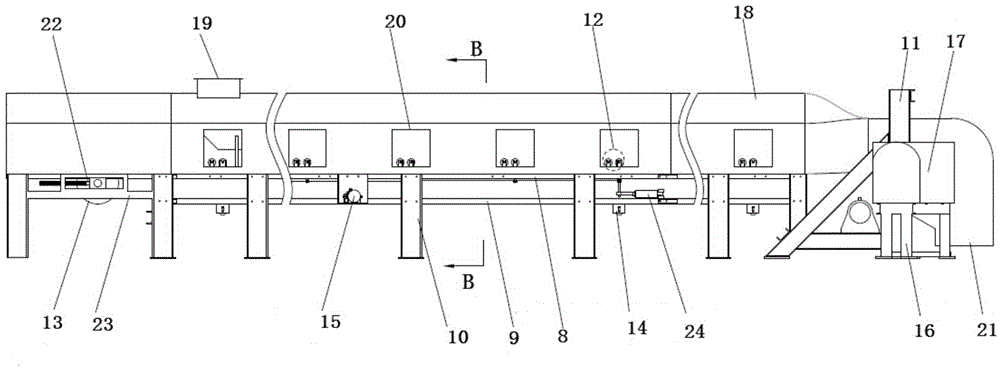

[0048] Such as image 3 The structural schematic diagram of the roller belt conveyor includes: intermediate frame, outriggers, drive roller, drive roller drive device, upper roller assembly, reversing roller, return roller assembly, ball screw drive and conveyor belt, Wherein, the intermediate frame includes an upper intermediate frame 8 and a lower intermediate frame 9, the upper intermediate frame 8 and the lower intermediate frame 9 are connected to the legs 10 with bolts, and the legs are fixedly supporting the intermediate frame. According to the length in the middle, how many legs are installed? One, the whole idler belt conveyor is stably fixed; the driving drum can be fixed on the front end of the intermediate frame by the driving drum bracket 11 alone, and correspondingly, the driving drum driving device is installed on one side of the driving drum to drive the driving drum to rotate. The upper idler assembly 12 is fixedly installed on the top of the upper intermediat...

Embodiment 3

[0065] In Example 2, the length of the upper intermediate frame and the lower intermediate frame is set to 6250 mm, and the installation distance is 357 mm. The upper intermediate frame and the lower intermediate frame are connected with the outriggers with bolts, and the outriggers are installed every 2084mm. The base of the upper idler group is installed on the upper intermediate frame with bolts, and one is installed every 1250mm, a total of 5 pieces; one side is installed with 3 sets, and a set of return idlers is installed every 2500mm, a total of 3 sets. The bearing seat of the horizontal roller is installed on the base of the upper roller group with bolts, and the installation distance between the left and right bearing seats (based on the axis of the threaded hole) is 920mm. The horizontal idler bearing is installed on the horizontal idler bearing seat, the installation height (based on the axis of the inner ring, and the distance from the lower intermediate frame) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com