Dewatering and drying treatment method used in biological sludge plant, sludge dewatering extruder and sludge drying extruder

A technology of biological sludge and treatment method, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Sludge can not be effective and other problems, to achieve the effect of low equipment maintenance cost, avoid secondary pollution, low moisture content of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

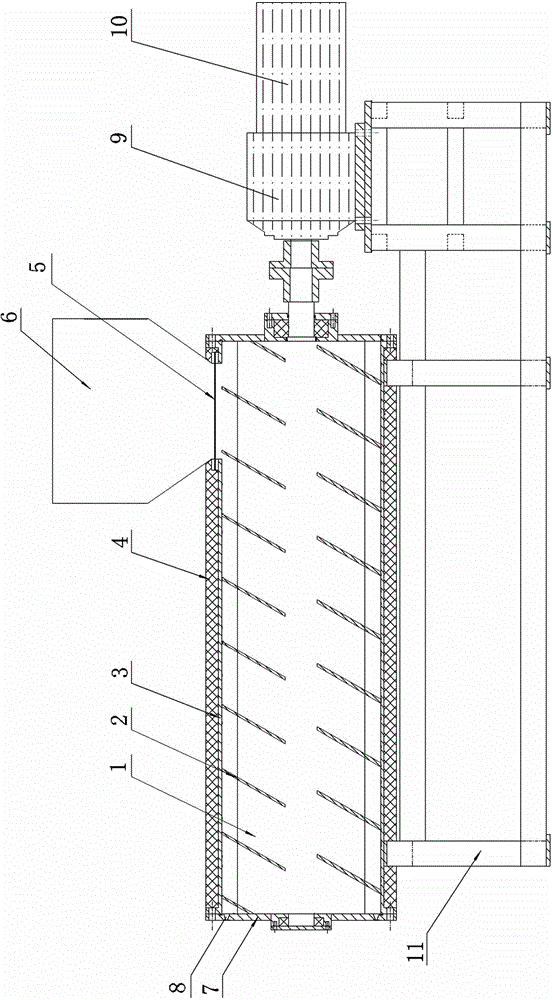

[0029] The method for dewatering and drying in a biological sludge plant of the present invention realizes the harmless treatment of biological sludge on-site in the sewage treatment plant. The process of its realization includes a sludge dewatering process and a sludge drying process:

[0030] 1) In the sludge dewatering process, the biological sludge generated from sewage treatment is added with a certain proportion of treatment chemicals, and the sludge dewatering extruder is used to dehydrate the thin sludge that is fully mixed with the treatment chemicals through a mixer. The moisture content of the sludge after dehydration is 70~75%;

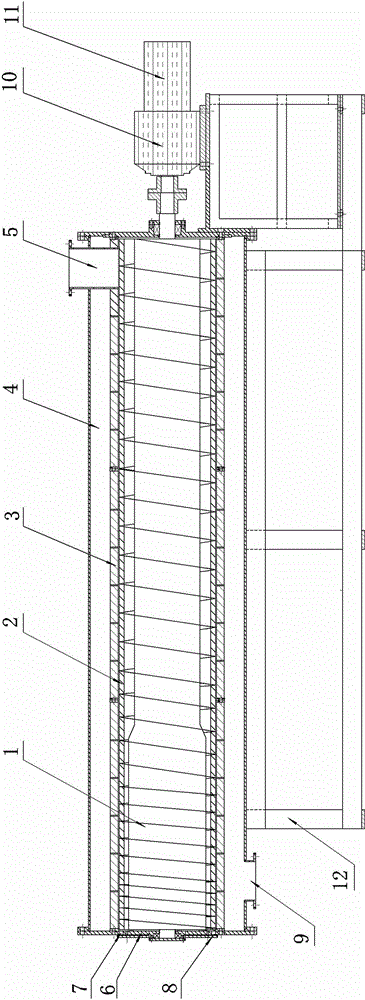

[0031] 2) In the sludge drying process, the dewatered sludge is first added with a certain proportion of sterilizing and disinfectant, and then mixed evenly and harmlessly treated, and then a certain proportion of dried sludge is added and the moisture content is 48-52% after mixing. A sludge drying extruder is used to dry the mixed sludge, and...

Embodiment 2

[0035] In the method for dehydration and drying in a biological sludge plant of this embodiment, the sludge dehydration process is as follows:

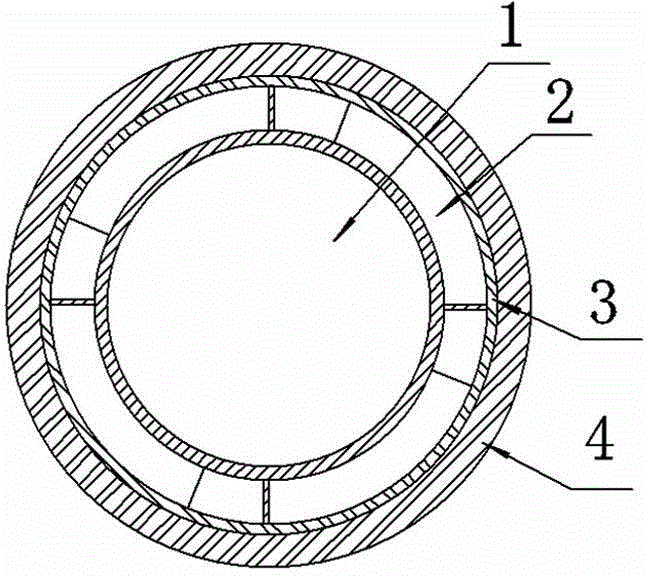

[0036] The biological sludge generated by the sewage treatment plant in the sewage treatment plant passes through the sludge sedimentation tank with a water content of about 99%. The thin sludge is pumped out from the bottom of the sedimentation tank by a screw pump. The pipeline is equipped with a treatment agent inlet and a mixer for metering. The pump quantitatively adds a certain proportion of the sludge treatment agent, the mixer fully mixes the thin sludge and the agent, and enters the filter barrel from the inlet of the sludge dewatering extruder; the screw pump and the agent metering pump are equipped with variable-speed motors to adjust The feed volume makes the dilute sludge and the treatment agent reach the best coordination state. The rotation speed of the sludge dewatering extruder is 10-40 rpm. The motor transmission drives...

Embodiment 3

[0040] In the dewatering and drying treatment method in the biological sludge plant of this embodiment, the dewatered sludge treatment process is as follows:

[0041] Install the horizontal sludge mixer under the dewatered sludge storage tank, open the gate, and the dewatered sludge will automatically flow into the mixer. First, add a certain proportion of the dewatered sludge to the dewatered sludge, stir it evenly and harmlessly treat it, and then use small loading The machine adds a certain proportion of dried sludge to adsorb and disperse the moisture of the dewatered sludge, and the sludge moisture content is 48-52% after being evenly stirred and put into the sludge storage tank. The agitated sludge is transported from the sludge storage tank to the feed hopper of the sludge drying extruder with a conveyor. The sludge enters the screw barrel from the feed port. The screw rotates rapidly under the drive of the motor transmission. The screw on the screw The propeller makes the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap