A kind of preparation method of vanadium pentoxide photochromic flexible epoxy resin film

A flexible epoxy resin, vanadium pentoxide technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve problems such as poor flexibility and ductility, and achieve the effect of improving flexibility and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

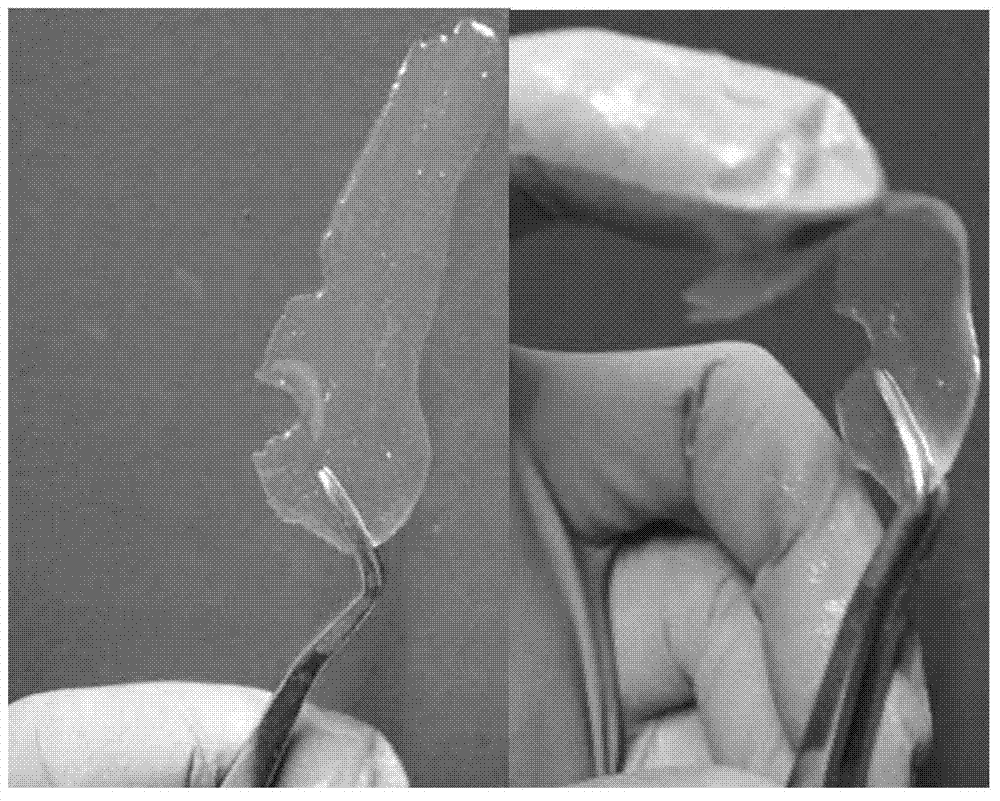

[0015] Specific embodiment one: In this embodiment, a method for preparing a vanadium pentoxide photochromic flexible epoxy resin film is realized according to the following steps:

[0016] 1. Take 7~9gV 2 o 5 Put the powder into an alumina crucible, heat it to melt, quickly pour it into 180-220ml of deionized water, stir it magnetically at a rate of 800-1000r / min for 1-3 hours, and obtain a vanadium pentoxide sol;

[0017] 2. Take 90-110ml of E44 type epoxy resin, add polydimethylformamide to dilute to 110-130ml, then add 25-35ml of polyamide curing agent and 5-7ml of vanadium pentoxide sol, mix well and let it stand Place until the air bubbles are discharged to obtain a mixed resin;

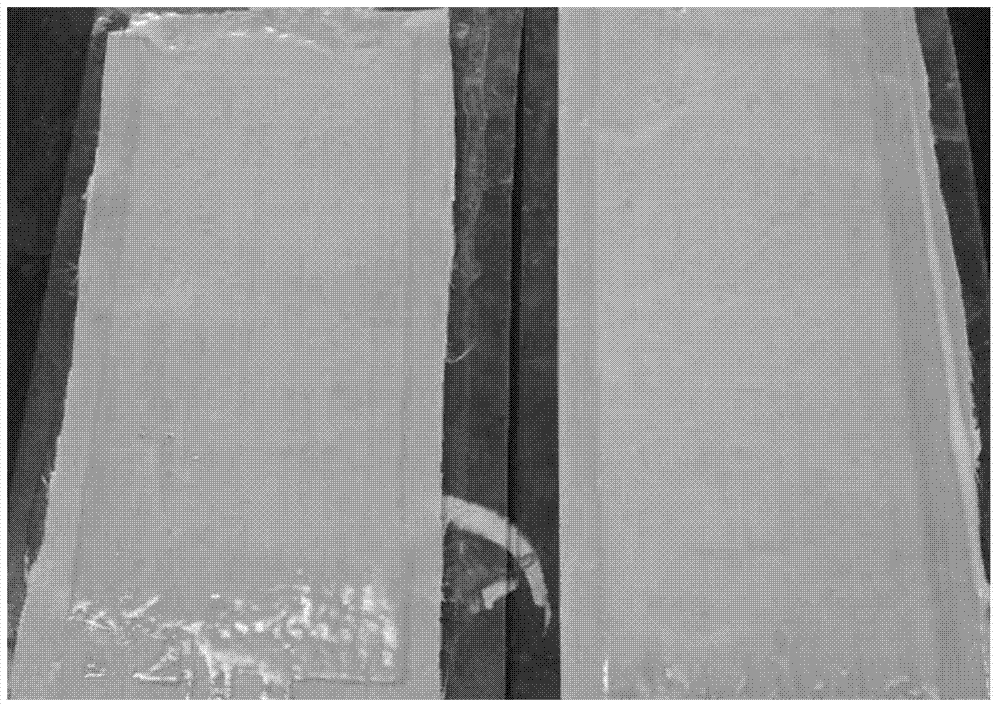

[0018] 3. Adjust the scraper of the film scraping machine to a height of 500 μm, pour 7-10ml of mixed resin on the surface of a glass plate with fiber cloth or a polytetrafluoroethylene plate, and scrape the film at a speed of 0.5-0.7m / min. Repeat scraping the film 2 to 3 times, then dry and...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: take 8gV in step one 2 o 5 The powder was put into an alumina crucible, heated to melt, quickly poured into 200ml of deionized water, and stirred magnetically at a rate of 900r / min for 2h. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment two is: get the E44 type epoxy resin of 100ml in the step 2, add polydimethylformamide and dilute to 120ml, then add the polyamide curing agent of 30ml and 6ml Vanadium pentoxide sol. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com