Medium-density silicone rubber for nuclear power

A silicone rubber and medium-density technology, applied in the field of silicone rubber, can solve the problems of inconvenient construction, easily damaged penetrating parts, high strength, etc., and achieve the effects of good sealing performance, easy decontamination on the surface, and good anti-staining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 nuclear power medium density silicone rubber

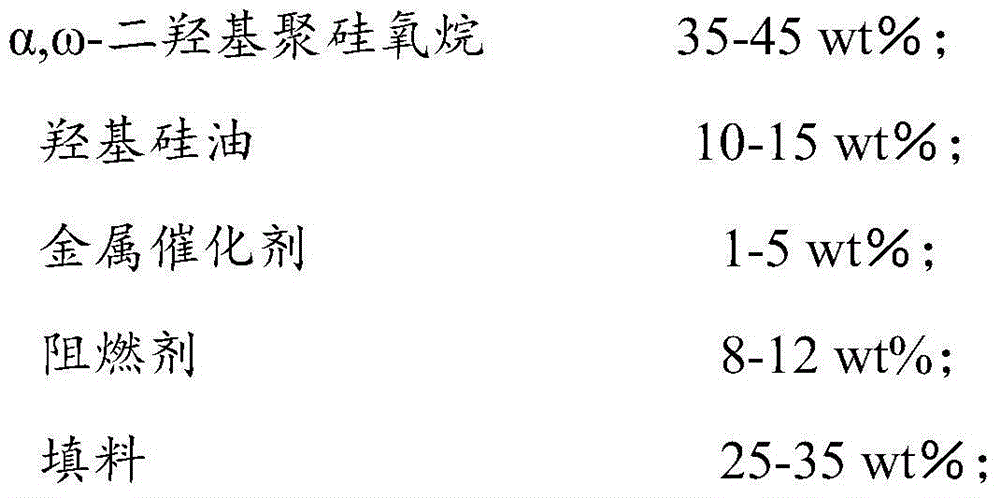

[0033] 1. Raw material composition

[0034] Component A: raw material ratio α, ω-dihydroxypolysiloxane 45kg; hydroxyl silicone oil 10kg; platinum catalyst 1kg; zinc borate 12kg; fumed silica 32kg.

[0035] Component B: α, ω-dihydroxypolysiloxane 35kg; hydroxyl silicone oil 10kg; hydrogen-containing silicone oil 10kg; aluminum hydroxide 10kg; fumed silica 35kg.

[0036] 2. Preparation method

[0037] 1) Preparation of component A: Add α,ω-dihydroxy polysiloxane and hydroxyl silicone oil in the raw materials of component A into the reaction kettle, mix for 20 minutes at 25°C and vacuum degree of 0.1MPa, and then add the above mixed solution Add metal catalysts, fillers and flame retardants, stir and mix with a high-speed disperser for 30 minutes, and vacuum degas for 40 minutes; obtain component A;

[0038] 2) Preparation of component B: Add α,ω-dihydroxy polysiloxane, hydrogen-containing si...

Embodiment 2

[0040] The preparation of embodiment 2 nuclear power medium density silicone rubber

[0041] 1. Raw material composition

[0042] Component A: raw material ratio α, ω-dihydroxypolysiloxane 35kg; hydroxyl silicone oil 15kg; platinum catalyst 5kg; zinc borate 10kg; fumed silica 35kg.

[0043] Component B: 45kg of α,ω-dihydroxy polysiloxane; 7kg of hydroxyl silicone oil; 15kg of hydrogen-containing silicone oil; 8kg of aluminum hydroxide;

[0044] 2. Preparation method

[0045] 1) Preparation of component A: Add α,ω-dihydroxypolysiloxane and hydroxyl silicone oil in the raw materials of component A into the reaction kettle, mix for 40min at 20°C and vacuum degree of 0.1MPa, and then add the above mixed solution Add metal catalysts, fillers and flame retardants, stir and mix with a high-speed disperser for 30 minutes, and vacuum degas for 30 minutes; obtain A component;

[0046] 2) Preparation of component B: Add α,ω-dihydroxypolysiloxane, hydrogen-containing silicone oil, and ...

Embodiment 3

[0048] The preparation of embodiment 3 nuclear power medium density silicone rubber

[0049] 1. Raw material composition

[0050] Component A: raw material ratio α, ω-dihydroxypolysiloxane 45kg; hydroxyl silicone oil 15kg; platinum catalyst 5kg; zinc borate 10kg; fumed silica 25kg.

[0051] Component B: α, ω-dihydroxy polysiloxane 40kg; hydroxyl silicone oil 5kg; hydrogen silicone oil 13kg; aluminum hydroxide 12kg; fumed silica 30kg.

[0052] 2. Preparation method

[0053] 1) Preparation of component A: Add α,ω-dihydroxy polysiloxane and hydroxyl silicone oil in the raw materials of component A into the reaction kettle, mix for 10 minutes at 35°C and a vacuum of 0.05MPa, and then add the above mixed solution Add metal catalysts, fillers and flame retardants, stir and mix with a high-speed disperser for 40 minutes, and vacuum degas for 40 minutes; obtain component A;

[0054] 2) Preparation of component B: Add α,ω-dihydroxy polysiloxane, hydrogen-containing silicone oil, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com