Giant magnetostriction material doped with trace non-solid-solution large atoms to cause distortion enhancement and preparation method

A magnetostrictive material and giant magnetostrictive technology, applied in the field of special functional magnetic materials, can solve the problem of no Fe-Ga magnetostrictive material, etc., and achieve the effect of increasing magnetostrictive performance, high performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

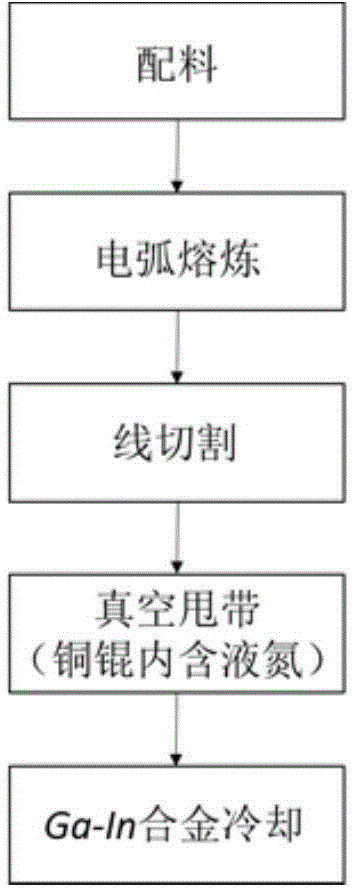

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: prepare high performance (Fe 0.725 Ga 0.275 ) 99.5 u 0.5 Magnetostrictive thin strip.

[0037] Step 1: Dosing according to the target composition plus burning loss: (Fe 0.725 Ga 0.275 ) 99.5 u 0.5 , and add 3wt% of Ga burnout and 5wt% of U burnout, wherein Fe with a purity of 99.999% and Ga and U with a purity of 99.99% are used.

[0038] Step 2: Smelting the master alloy with a vacuum non-consumable arc melting furnace. Put the ingredients obtained in step 1 into the furnace of the vacuum non-consumable arc melting furnace, and vacuumize to 4×10 -3 Pa, then filled with 400Pa argon and then evacuated to 4×10 -3 Pa for scrubbing. After washing for 3 times, fill with 1Pa argon gas, melt the ingredients under the melting current of 120A, the melting time is 4min, and repeat the melting 5 times to obtain the master alloy ingot.

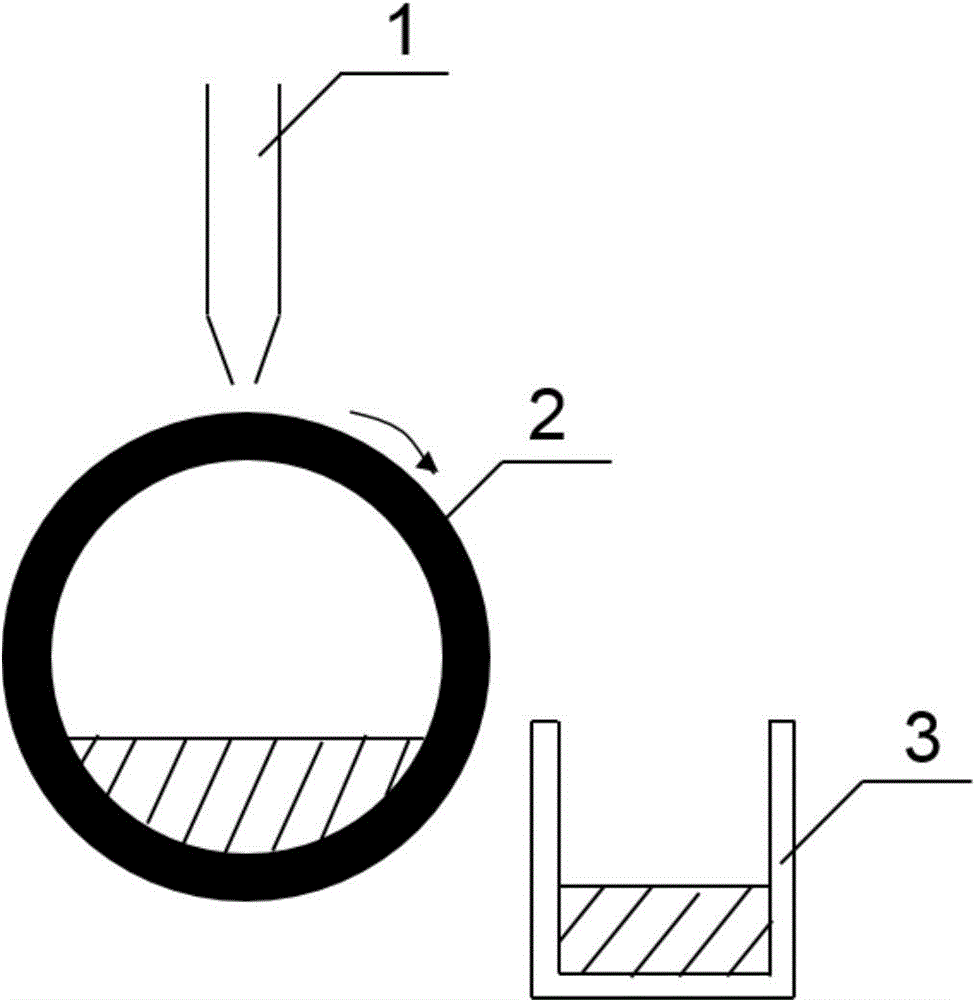

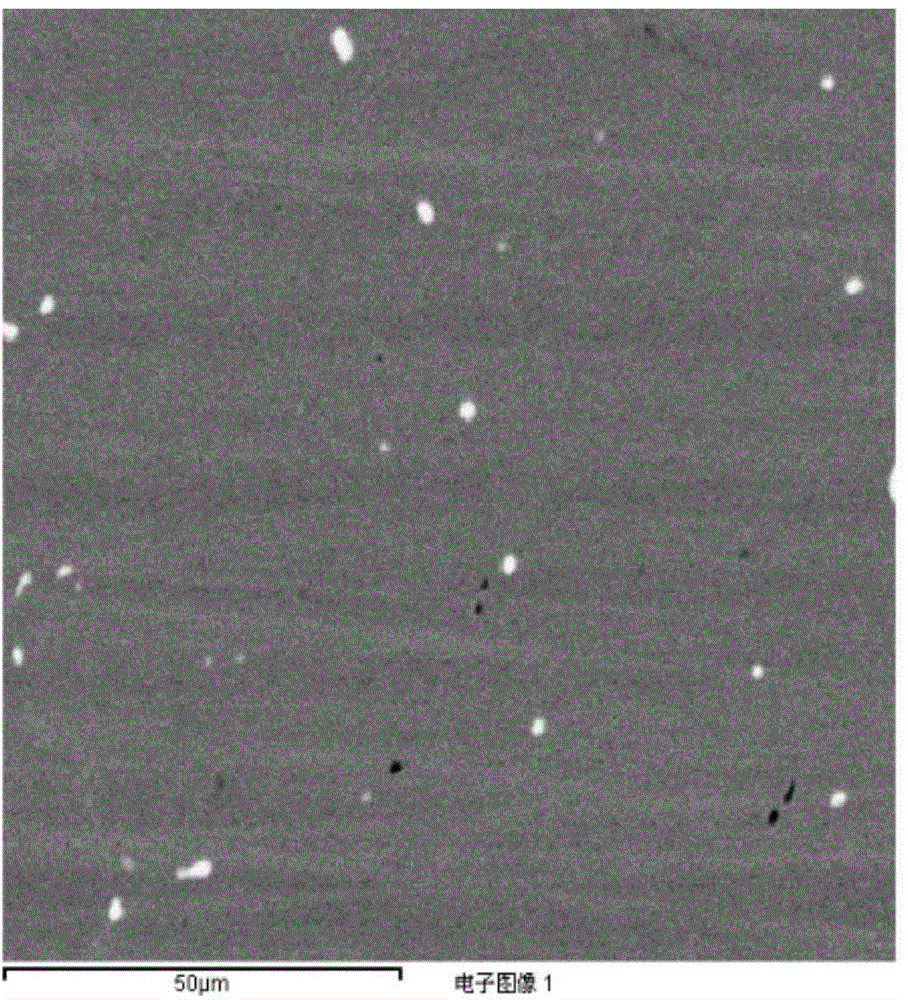

[0039] Step 3: Cut the alloy ingot smelted in step 2 into blocks with a single-roller spinning belt, and clean the surfac...

Embodiment 2

[0043] Embodiment 2: prepare high performance (Fe 0.83 Ga 0.17 ) 99.8 R 0.2 Magnetostrictive thin strip.

[0044] Step 1: Dosing according to the target composition plus burning loss: (Fe 0.83 Ga 0.17 ) 99.8 R 0.2 , and add 3wt% of Ga burnout and 5wt% of R burnout, in which Fe with a purity of 99.999% and Ga and R with a purity of 99.99% are used.

[0045] Step 2: Smelting the master alloy with a vacuum non-consumable arc melting furnace. Put the ingredients obtained in step 1 into the furnace of the vacuum non-consumable arc melting furnace, and vacuumize to 4×10 -3 Pa, then filled with 400Pa argon and then evacuated to 4×10 -3 Pa for scrubbing. After washing for 3 times, fill with argon gas of 1 Pa, melt the ingredients under the melting current of 130A, the melting time is 4min, and repeat the melting 5 times to obtain the master alloy ingot.

[0046]Step 3: Cut the alloy ingot smelted in step 2 into blocks with a single-roller spinning belt, and clean the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com