A method for strengthening rammed earth walls

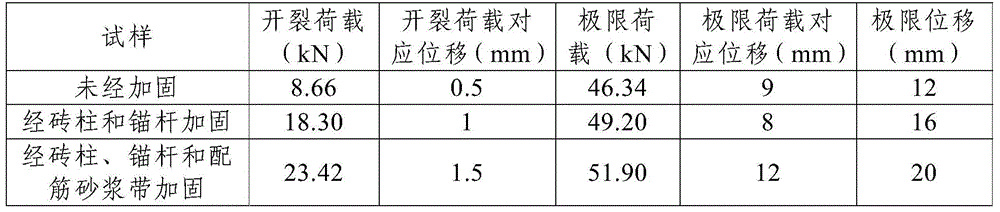

A technology of rammed earth walls and walls, which is applied in building maintenance, construction, building construction, etc., can solve the problems of poor seismic performance of raw soil structures, difficulties in demolition and reconstruction, and achieve improved seismic performance, significant seismic performance, and shear resistance. The effect of increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

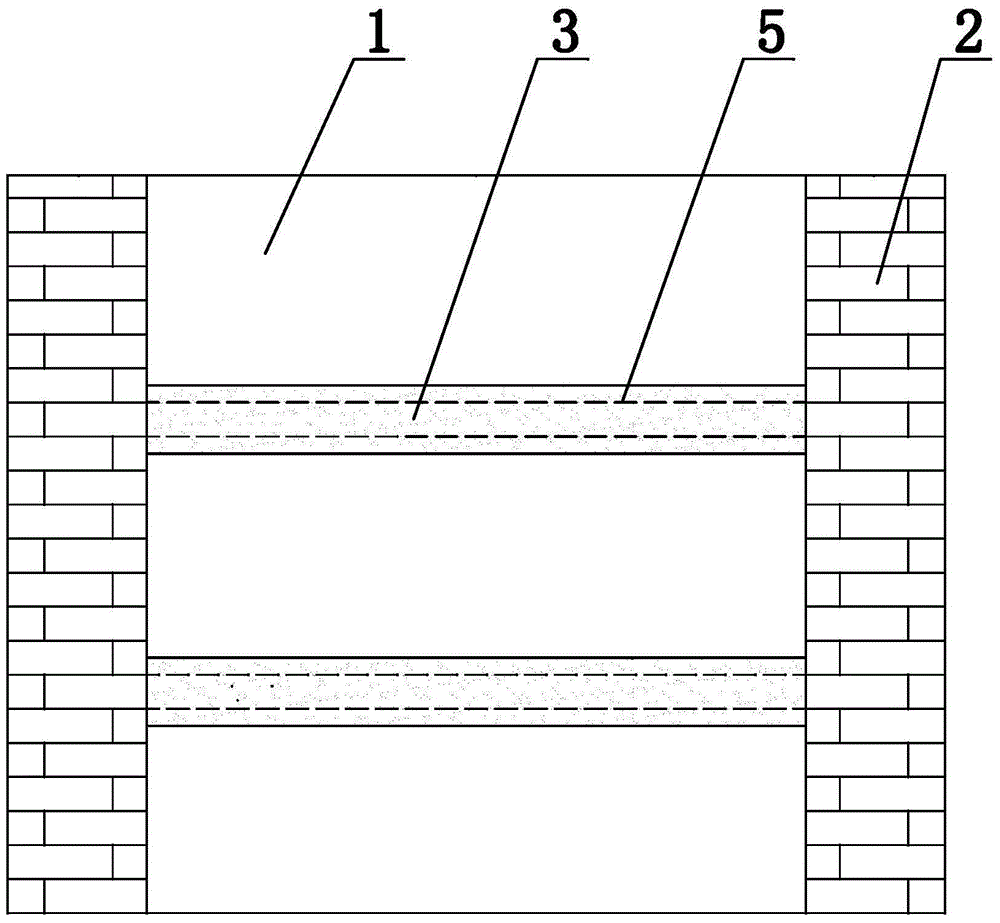

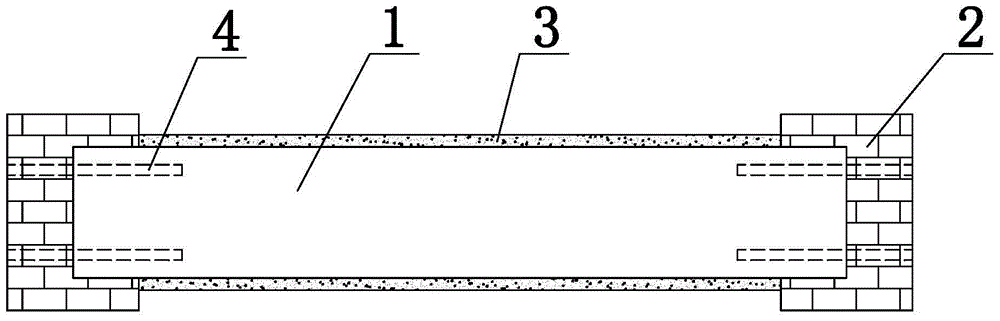

[0029] Take the wall size 4950mm (length) × 3900mm (height) × 720mm (thickness) as an example, such as figure 1 and figure 2 As shown, the rammed earth wall reinforcement method of the present embodiment comprises the following steps:

[0030] Step 1, building brick columns 2 for wrapping both ends of the rammed earth wall 1 at both ends of the rammed earth wall 1, and filling the gap between the rammed earth wall 1 and the brick columns 2 with cement mortar during the masonry process;

[0031] Step 2. When the brick column 2 is built to 1 / 4 of the height of the rammed earth wall 1, holes are drilled at both ends of the rammed earth wall 1, and then the holes at both ends of the rammed earth wall 1 are inserted and the surface is coated with cement mortar continue to build the brick column 2 and press the anchor bar 4 outside the rammed earth wall 1 into the brick column 2, and use cement mortar to fill the gap between the rammed earth wall 1 and the brick column 2 during th...

Embodiment 2

[0038] Take the wall size of 5500mm (length) × 3600mm (height) × 720mm (thickness) as an example, such as figure 1 and figure 2 As shown, the rammed earth wall reinforcement method of the present embodiment comprises the following steps:

[0039] Step 1, building brick columns 2 for wrapping both ends of the rammed earth wall 1 at both ends of the rammed earth wall 1, and filling the gap between the rammed earth wall 1 and the brick columns 2 with cement mortar during the masonry process;

[0040] Step 2. When the brick column 2 is built to 1 / 5 of the height of the rammed earth wall 1, holes are drilled at both ends of the rammed earth wall 1, and then the holes at both ends of the rammed earth wall 1 are inserted and the surface is coated with cement mortar continue to build the brick column 2 and press the anchor bar 4 outside the rammed earth wall 1 into the brick column 2, and use cement mortar to fill the gap between the rammed earth wall 1 and the brick column 2 during...

Embodiment 3

[0047] Take the wall size of 5800mm (length) × 3900mm (height) × 720mm (thickness) as an example, such as figure 1 and figure 2 As shown, the rammed earth wall reinforcement method of the present embodiment comprises the following steps:

[0048] Step 1, building brick columns 2 for wrapping both ends of the rammed earth wall 1 at both ends of the rammed earth wall 1, and filling the gap between the rammed earth wall 1 and the brick columns 2 with cement mortar during the masonry process;

[0049]Step 2. When the brick column 2 is built to a height of 900 mm, holes are drilled at both ends of the rammed earth wall 1, and then anchor rods 4 coated with cement mortar are inserted into the holes at both ends of the rammed earth wall 1, and the masonry is continued The brick column 2 and the anchor rod 4 are located outside the rammed earth wall 1 and pressed tightly in the brick column 2, and the gap between the rammed earth wall 1 and the brick column 2 is filled with cement m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com