Water controlling and acid fracturing method suitable for carbonate reservoir

A carbonate rock reservoir, water acid technology, applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of rising oil-water contact, intensified water flooding, and reduced water avoidance height, etc. problems, to achieve the effect of slowing the rising speed of water, controlling the high elongation, and suppressing the excessive elongation of the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

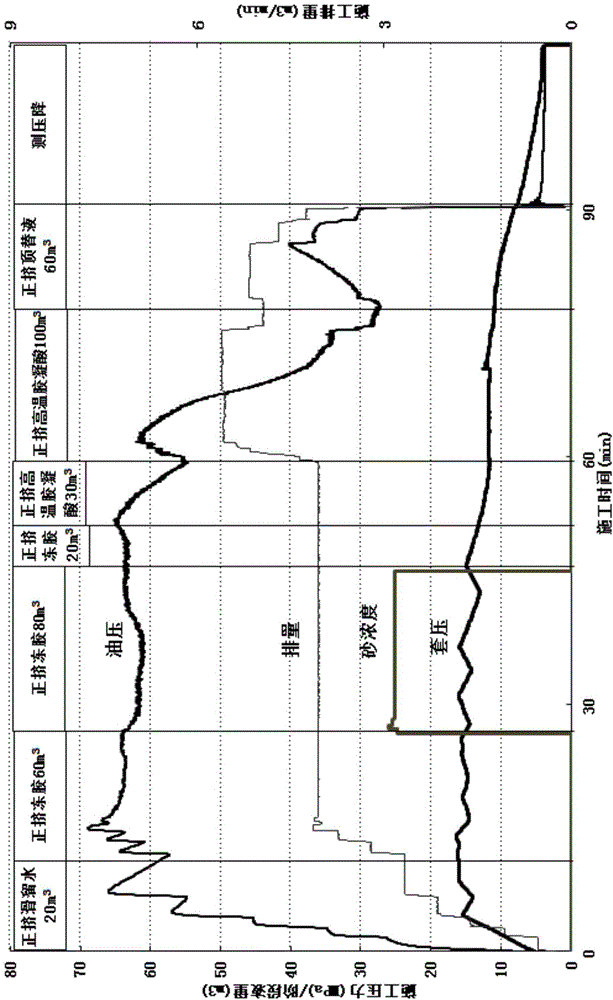

Method used

Image

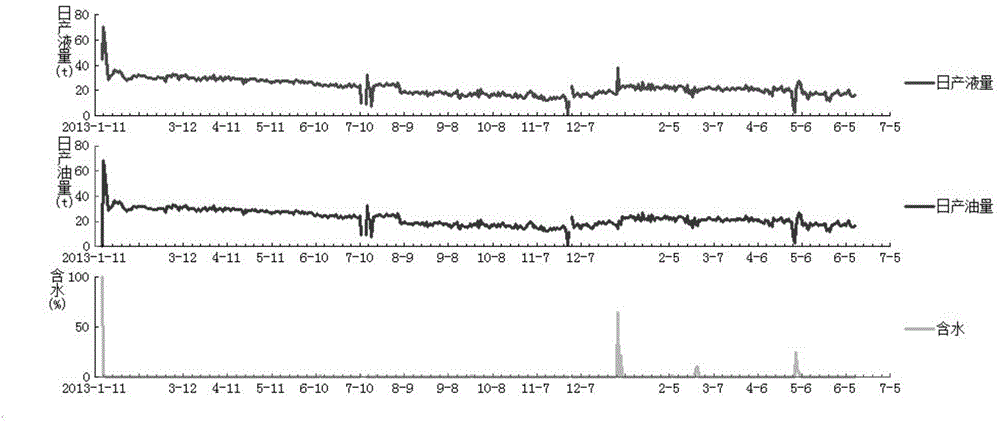

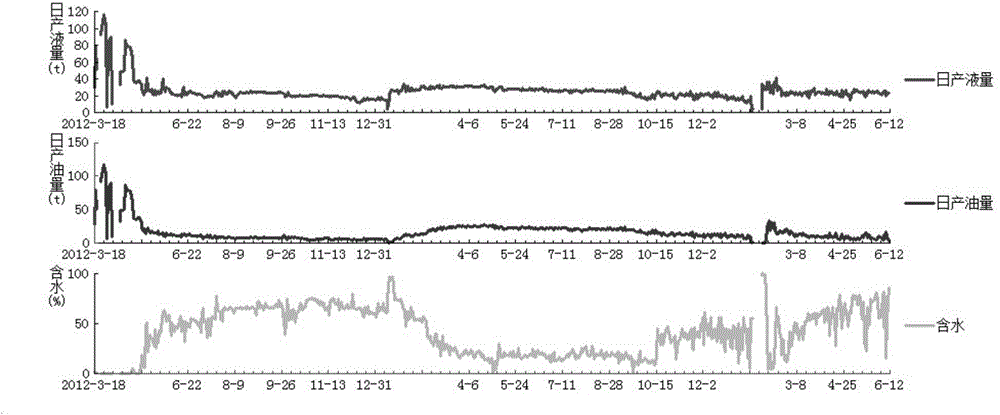

Examples

Embodiment Construction

[0031] In order to fully understand the purpose, features and effects of the present invention, the present invention will be further described in detail through the following specific embodiments, but the present invention is not limited thereto. Device and processing method of the present invention except following content, all the other all adopt the routine method or device of this field.

[0032]The method of the present invention mainly adopts the coated sand with the effect of blocking water and seeping oil as the supporting ceramsite. Coated sand is formed by coating the outer layer of quartz sand with new polymer materials (mainly thermoplastic phenolic resin, urotropine and reinforcing agent are used as raw materials to coat the surface of quartz sand grains), and the thickness of the coating layer is 10-12 μm , the direction of the capillary force formed on the surface with oil wettability is opposite to the direction of the water flooding pressure difference, forci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com