Integrated thrust bearing shell

A thrust bearing bush and integral technology, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inseparability, scrapping of bearing bushes, and affecting the use effect, etc., achieve excellent heat dissipation performance, improve quality, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

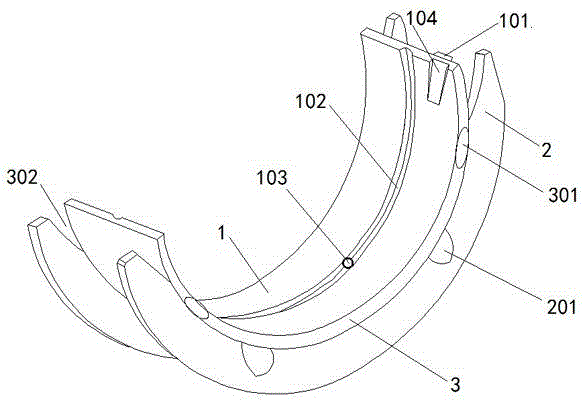

[0022] Embodiment one: if figure 1 As shown, the integral thrust bearing includes a thrust bearing body 1, one end of the thrust bearing body 1 is provided with a positioning lip 101, and both sides of the thrust bearing body 1 extend outward along a direction perpendicular to the thrust bearing body 1. There is a thrust plate 2, a step 3 is formed between the thrust plate 2 and the thrust bearing body 1, and a positioning hole 301 is provided on the step 3, and there are 4 positioning holes 301 in total; there are first gaps 302 at both ends of the step 3 , there are four first notches 302 in total; an oil groove 102 is provided in the middle of the thrust bearing body 1, and the oil groove 102 extends along the axial direction of the thrust bearing body 1 to both ends of the thrust bearing body 1, and the oil groove 102 connects the thrust bearing The body 1 is divided into two parts; an oil hole 103 is provided in the middle of the oil groove 102; the inner surface of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com