Method of inspecting a generator air-gap

An air gap and air gap inspection technology, which is used in motor generator testing, motor generator manufacturing, wind power generation, etc. Easy to identify, fast and easy to determine, the effect of accurate air gap analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

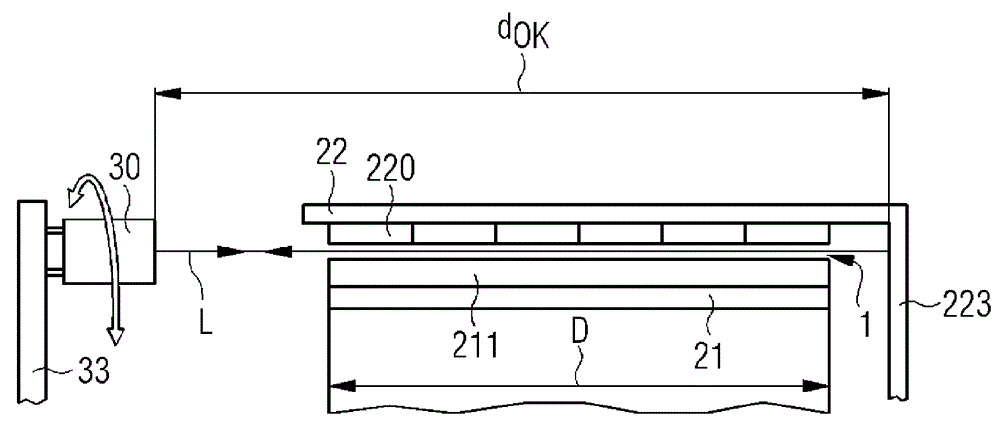

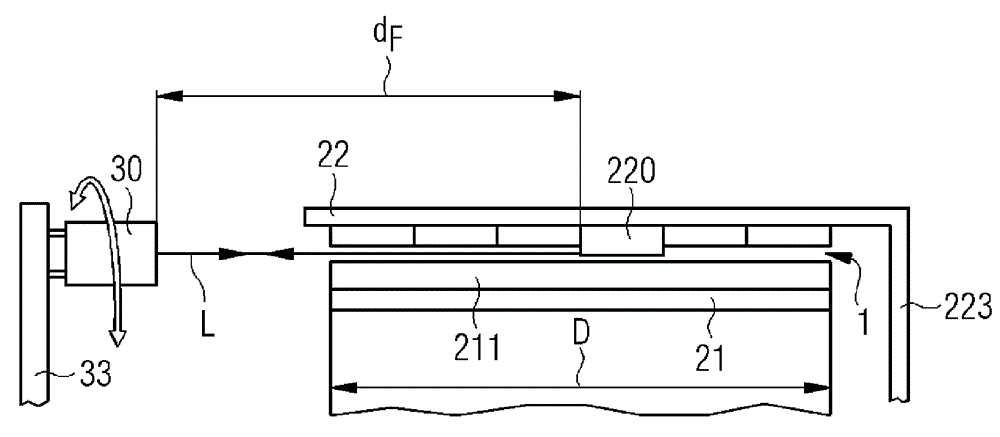

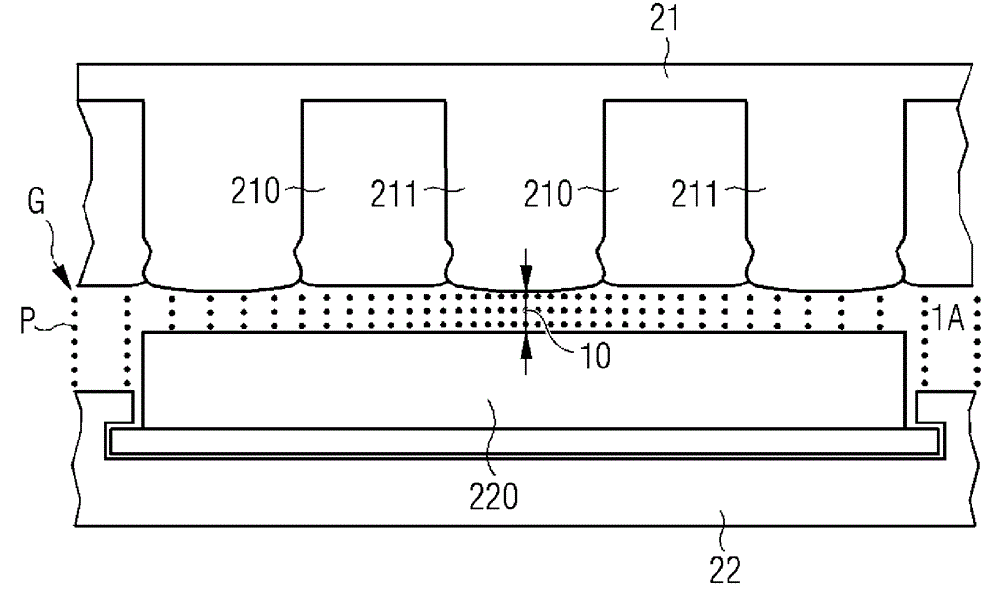

[0032] figure 1 is a simplified schematic diagram showing an inspection scenario comprising an embodiment of an air gap inspection device 3 according to the invention and a generator 2 under inspection. For the sake of clarity, the figure shows only a simplified cross-section through the generator 2 and only the relevant components, such as the rotor 22, poles 220, stator 21, stator windings 211 and rear cover 223 of the rotor housing. The length of the air gap 1 is substantially equivalent to the length D of the rotor slot holding the plurality of magnetic poles 220 . The stator 21 and the rotor 22 are arranged around the axis of rotation R of the generator. The air gap inspection device 3 includes a laser module 30 , a calculation unit 31 , an analysis unit 32 and a processing unit 34 such as a microprocessor and a memory module 35 . The memory module 35 is used to store data describing various characteristics of the ideal or desired air gap shape, as will be explained bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com