A dual-mode alternating motion linear motor module

A linear motor, alternating motion technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of insensitive and fast response, low equipment positioning accuracy, low dynamic response performance, etc. The effect of improved dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

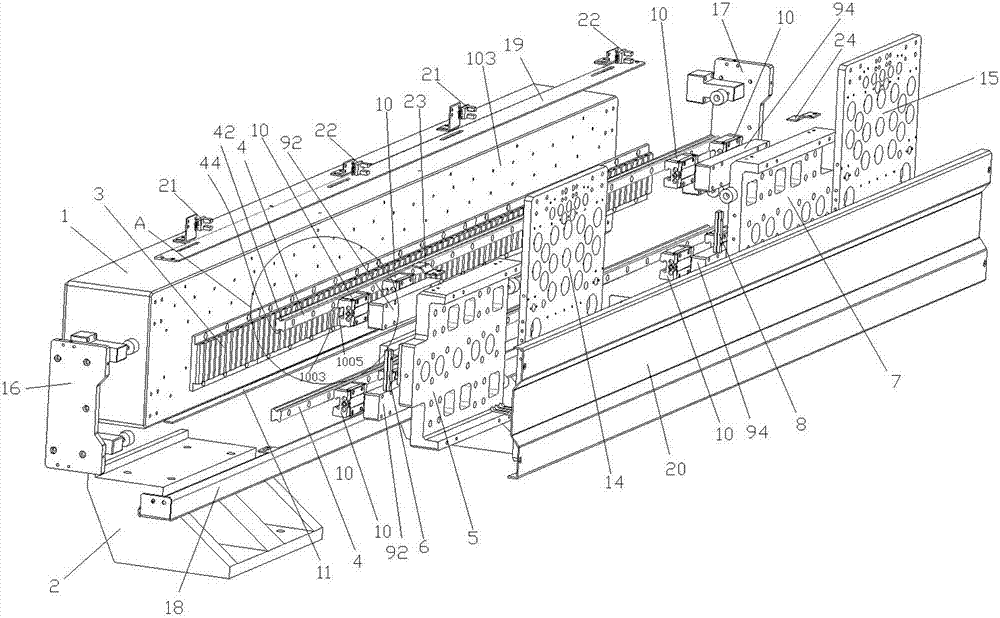

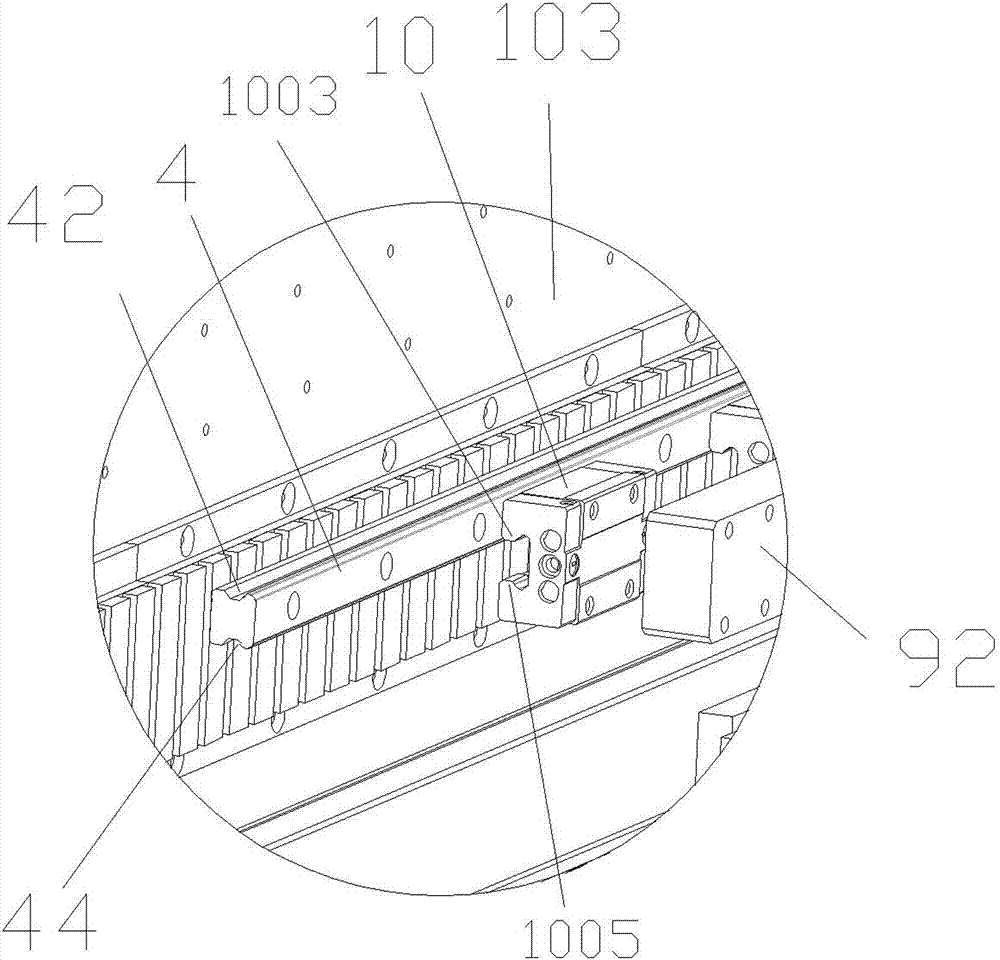

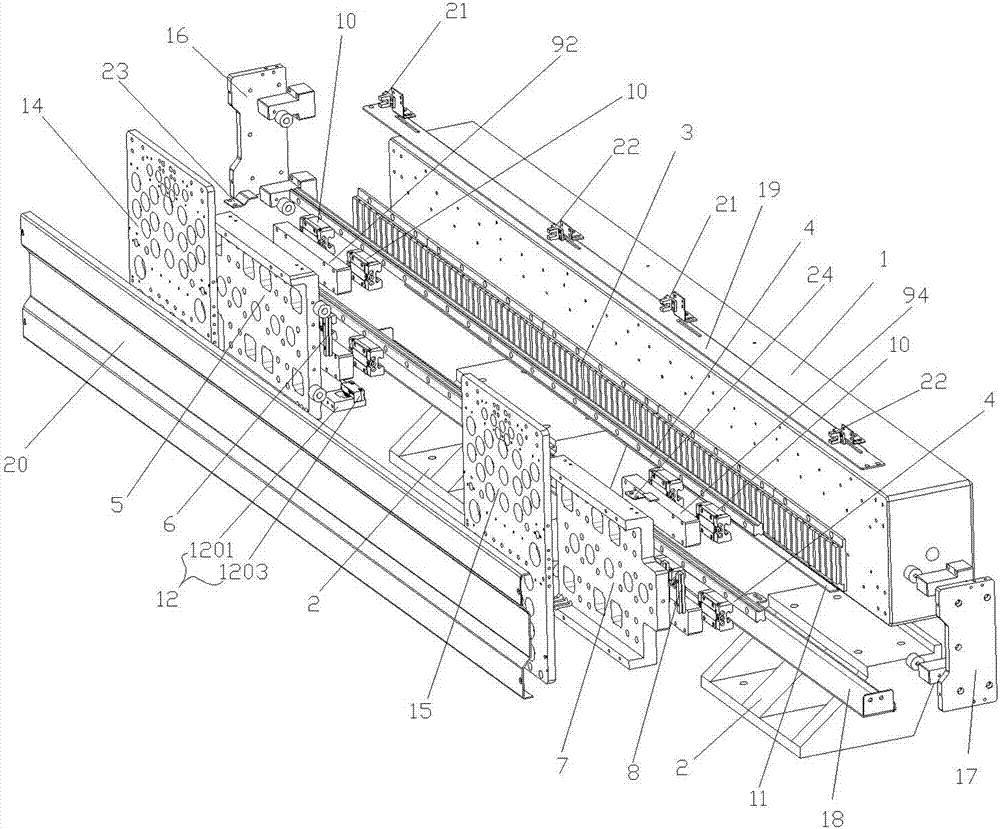

[0043] see Figure 1 to Figure 5 , a dual-mode alternating motion linear motor module, which includes a module mounting base 1, two module fixing bases 2, a linear motor stator 3, two linear guide rails 4, a left mover mounting plate 5, A left linear motor coil mover 6, a right mover mounting plate 7, a right linear motor coil mover 8, four slider connecting blocks (unlabeled), eight guide rail sliders 10, a grating ruler 11. A left mover grating ruler reading device 12, a right mover grating ruler reading device (not shown in the figure), a left module and working head connecting plate 14, a right module and working head connecting plate 15, A module left sealing plate 16, a module right sealing plate 17, a lower dust cover 18, an upper dust cover 19, a front dust cover 20, two left mover strokes Origin / limit sensing device 21, two right mover stroke origin / limit sensing devices 22, one left mover stroke origin / limit sensor sheet 23, one right mover stroke origin / limit senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com