An epoxy resin composition and its applications

A technology of epoxy resin and liquid epoxy resin, which is applied in the direction of epoxy resin coating, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0082] I. Raw materials:

[0083]

[0084]

[0085] II. Test method:

[0086]

[0087]

example 1

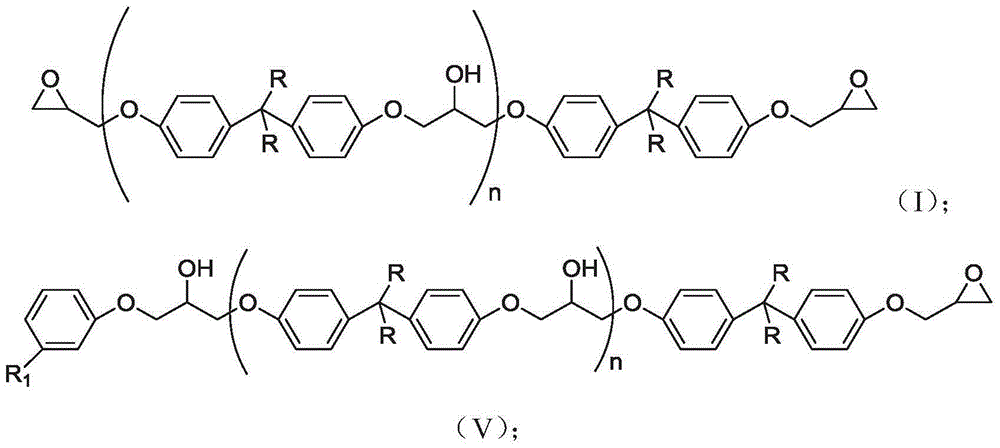

[0089] 92 parts by weight of D.E.R. TM 331 and 8 parts by weight cardanol were mixed in a flask under nitrogen. After the mixture reached 90° C., 200 ppm ethyltriphenylphosphonium acetate (70 wt. % in methanol) was added as a catalyst. The mixture was heated to 180°C and maintained at this temperature for 2 hours. Epoxy resin A is obtained. The product contained about 81 wt.% compound (I) and about 19 wt.% compound (V).

example 2

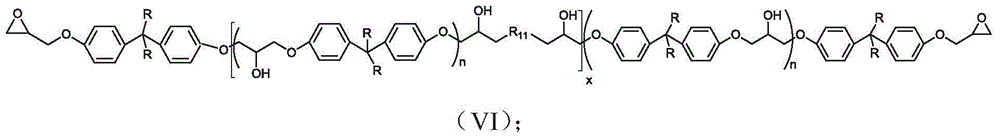

[0091] 85 parts by weight of D.E.R. TM 331. 7.5 parts by weight of cardanol and 7.5 parts by weight of cardol were mixed under nitrogen. After the mixture reached 90° C., 300 ppm ethyltriphenylphosphonium acetate (70 wt. % in methanol) was added as a catalyst. The mixture was heated to 170°C and maintained at this temperature for 3 hours. Obtain epoxy resin B. The product contained about 57 wt.% compound (I), 17 wt.% compound (V) and 26 wt.% compound (VI).

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com