A kind of natural polysaccharide-based hydrogel and its preparation and application in eye conjunctival repair

A natural polysaccharide and gel technology, applied in medical science, prosthesis, etc., can solve the problems of poor recovery of injectable hydrogel, unsuitable for surgical operation, cytotoxicity, etc., to inhibit the growth of fibroblasts and promote epithelial Effect of cell growth and protection of surgical wound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of maleylated chitosan / mercaptolated hyaluronic acid injectable hydrogel

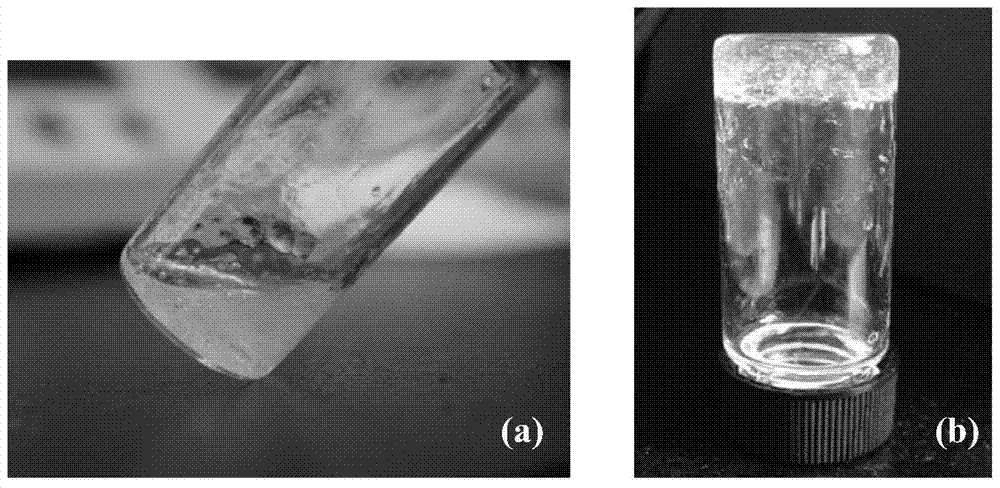

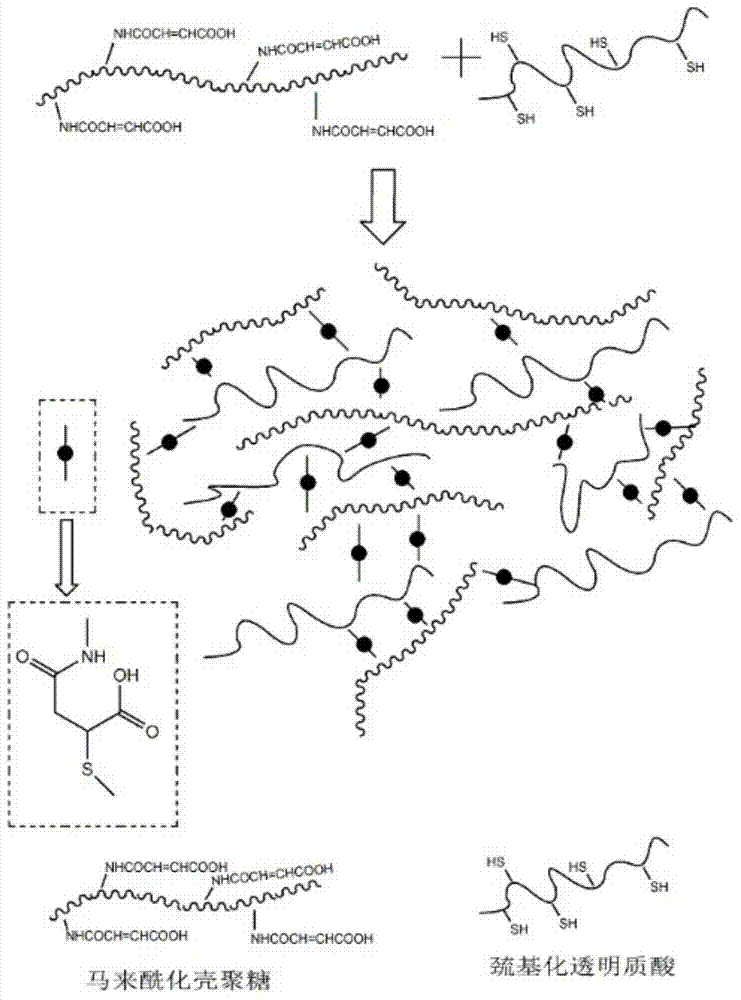

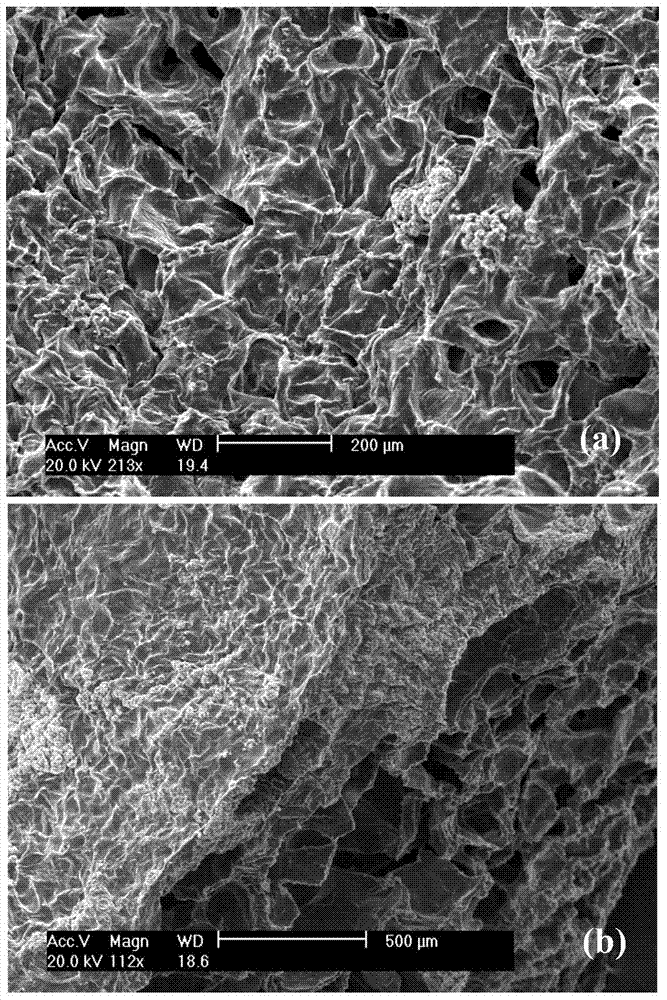

[0040]Add 0.4g of thiolated hyaluronic acid into 10mL of deionized water, and fully dissolve to obtain liquid A with a mass-volume ratio of thiolated hyaluronic acid of 0.04g / mL; add 0.15g of maleoylated chitosan into 10mL of deionized water , after fully dissolving to obtain maleylated chitosan mass volume ratio of 0.015g / mL liquid B; slowly pour an equal volume of liquid B into liquid A under magnetic stirring, and mix evenly; 58 wt.% sodium β-glycerophosphate solution was added dropwise with stirring to adjust the pH to 7, and then incubated in a constant temperature water bath at 37°C for 24 hours to form a pale yellow transparent gel. The prepared maleylated chitosan / mercaptolated hyaluronic acid injectable hydrogel was tested and analyzed. The gel time measured by the method of inverting the vial is 15min, and the schematic diagram of the gel process is as follows f...

Embodiment 2

[0041] Example 2: Preparation of maleylated chitooligosaccharide / mercaptolated hyaluronic acid injectable hydrogel

[0042] The preparation of maleylated chitosan oligosaccharide: according to chitosan oligosaccharide repeating unit and maleic anhydride mol ratio is the ratio of 2:1, in the there-necked flask that fills 2wt.% chitosan oligosaccharide solution, add maleic anhydride, room temperature N 2 After 24 hours of protection reaction, freeze-dry, wash the freeze-dried sample with acetone solution, and vacuum-dry to obtain maleylated chitosan oligosaccharide.

[0043] Add 0.1g of thiolated hyaluronic acid into 5mL of deionized water, and fully dissolve to obtain liquid A with a mass-volume ratio of thiolated hyaluronic acid of 0.02g / mL; add 0.0375g of maleoylated chitosan oligosaccharide into 5mL of deionized water , after fully dissolving to obtain maleylated chitosan oligosaccharide mass-volume ratio of 0.0075g / mL liquid B; under magnetic stirring, slowly pour an equal ...

Embodiment 3

[0044] Example 3: Preparation of itaconicated chitosan / mercaptolated hyaluronic acid injectable hydrogel

[0045] The preparation of itaconic acylated chitosan: according to the ratio of chitosan repeating unit and itaconic anhydride mol ratio being 2:1, add itaconic anhydride in the there-necked flask that fills 2wt.% chitosan solution, room temperature N 2 After 24 hours of protection reaction, dialyze for 3 days and freeze-dry to obtain the preparation of itaconylated chitosan.

[0046] Add 0.6g of thiolated hyaluronic acid into 10mL of deionized water, fully dissolve to obtain liquid A with a mass-volume ratio of thiolated hyaluronic acid of 0.06g / mL; add 0.36g of itaconylated chitosan into 10mL of deionized water , after fully dissolving to obtain itaconylated chitosan mass-volume ratio of 0.036g / mL liquid B; slowly pour an equal volume of liquid B into liquid A under magnetic stirring, and mix evenly; Add 58wt.% sodium β-glycerophosphate solution drop by drop under stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com