Compressed air foam zone control cabinet

A technology of compressed air foam and partitioned control box, applied in fire rescue and other directions, can solve the problems of structure layout, high space size requirements, easy to miss the best fire extinguishing time, and large space occupation, so as to shorten the conveying time and achieve a compact structure. , The effect of convenient installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

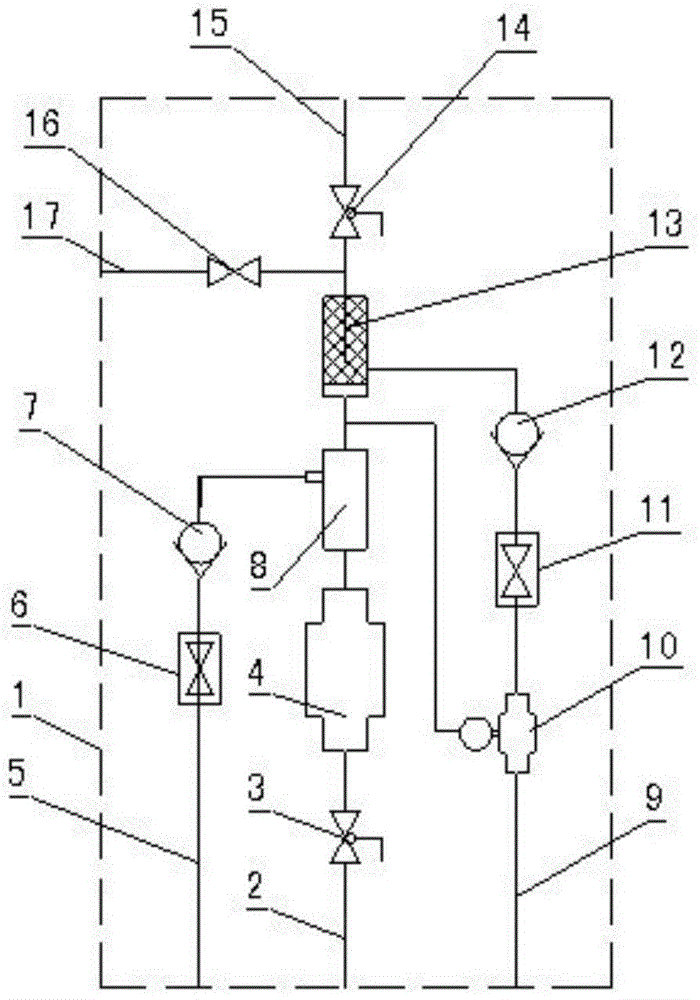

[0023] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

[0024] Such as figure 1 The partition control boxes shown are distributed in the fire protection area, and the housing 1 of each partition control box is respectively provided with a water supply branch pipe 2, a foam liquid input branch pipe 5 and an air supply branch pipe 9.

[0025] The water supply branch pipe 2 is connected with the water supply main pipe, and the water supply branch pipe is connected with the first signal butterfly valve 3 and the deluge valve 4 in sequence, and the outlet of the deluge valve 4 is connected to the water inlet of the foam proportional mixer 8 .

[0026] The foam liquid input branch pipe 5 is connected with the foam liquid output main pipe of the foam liquid storage tank, and the foam liquid input branch pipe 5 is connected with the first solenoid valve 6 and the first one-way valve 7 in turn, and the first solenoid valve 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com