Small-sized tower-shaped combined type waste gas treatment device

A waste gas treatment equipment and combined technology, which is applied in the fields of small tower-shaped combined waste gas treatment system, construction paint in the coating industry, treatment of sticky particles of paint and organic waste gas treatment device, which can solve the problem of large footprint and low cost. , miniaturization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

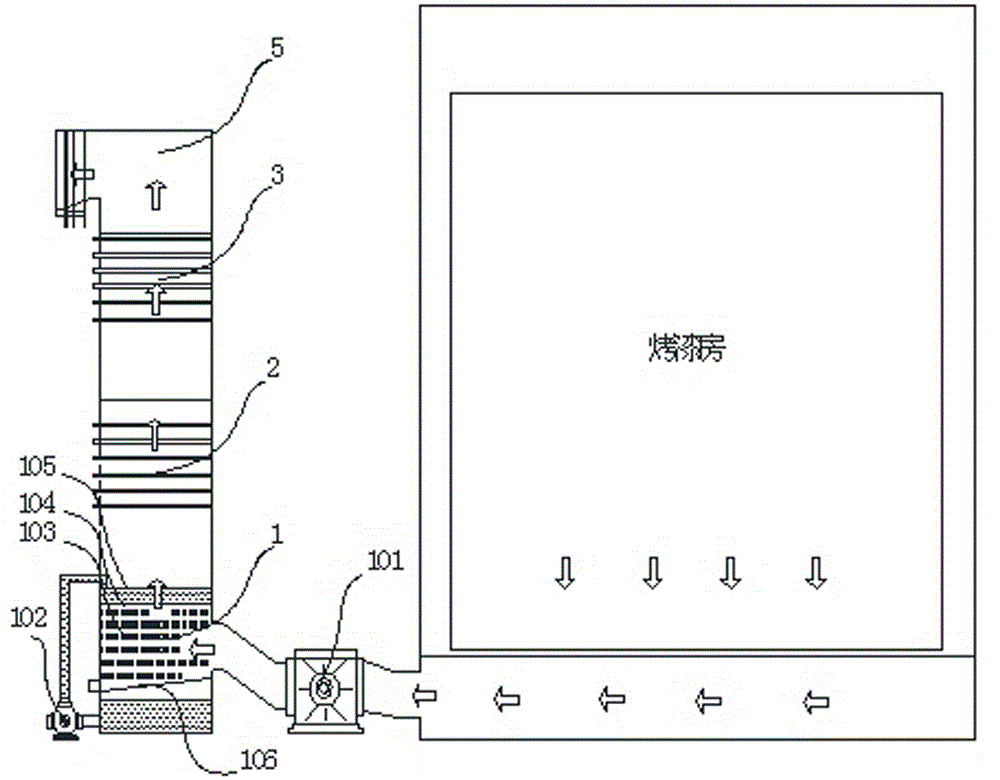

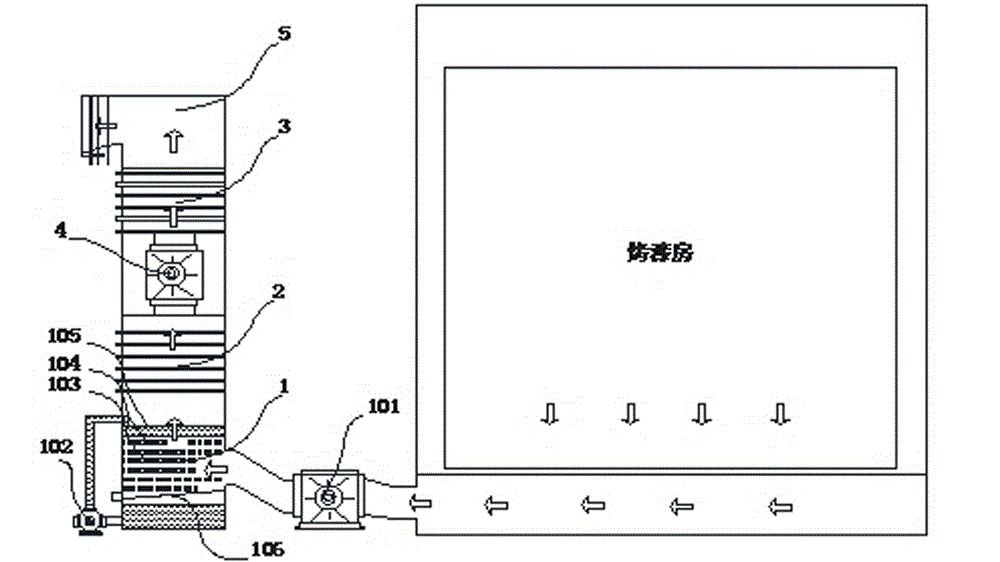

[0014] A small tower-shaped combined waste gas treatment equipment, including a dust removal device 1, a photodecomposition device 2, and an adsorption device 3. Dust removal device 1 , photodecomposition device 2 and adsorption device 3 are all installed in a vertical box 5 , and the installation sequence from bottom to top is dust removal device 1 , photodecomposition device 2 and adsorption device 3 .

[0015] In the exhaust gas treatment equipment described above, other exhaust gas treatment links can also be further added to improve the degree of exhaust gas treatment.

[0016] In the waste gas treatment equipment described above, in order to increase the speed of waste gas flow, a fan 4 can be arranged between the photodecomposition device and the adsorption device.

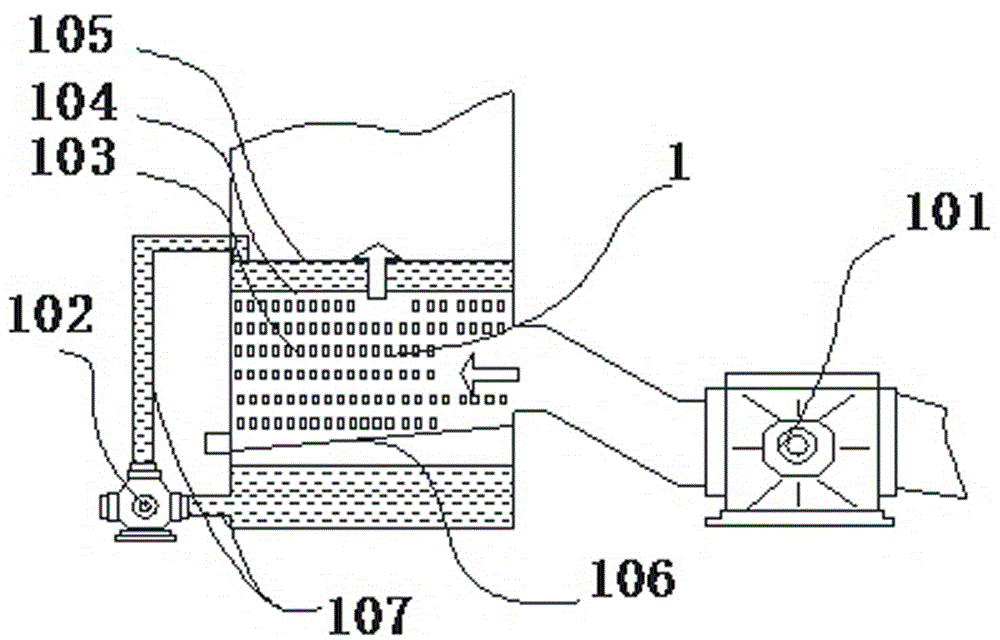

[0017] Preferably, the dust removal device 1 is a water curtain gravity dust removal device 1 , the photodecomposition device 2 is a UV high-energy high-ozone ultraviolet light decomposition device 2 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com