Method and device for treating waste gas and remediating soil by comprehensively utilizing agricultural wastes

A technology for agricultural waste and soil remediation, which is applied in the field of comprehensive utilization of agricultural waste for waste gas treatment and soil remediation, can solve problems such as air pollution, impact on removal efficiency, and increase in investment and operation costs, and achieves solutions to rural environmental pollution and atmospheric environment. Effects of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

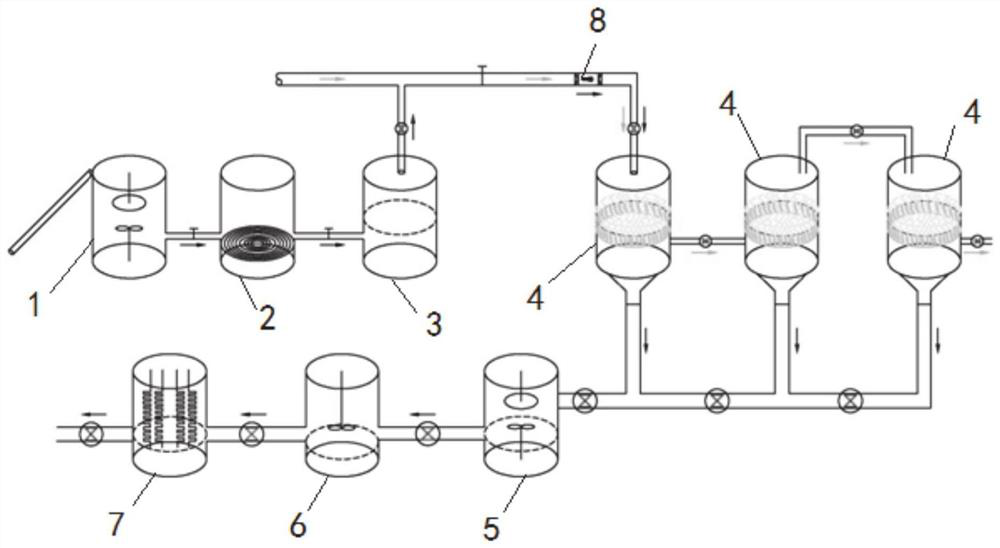

Image

Examples

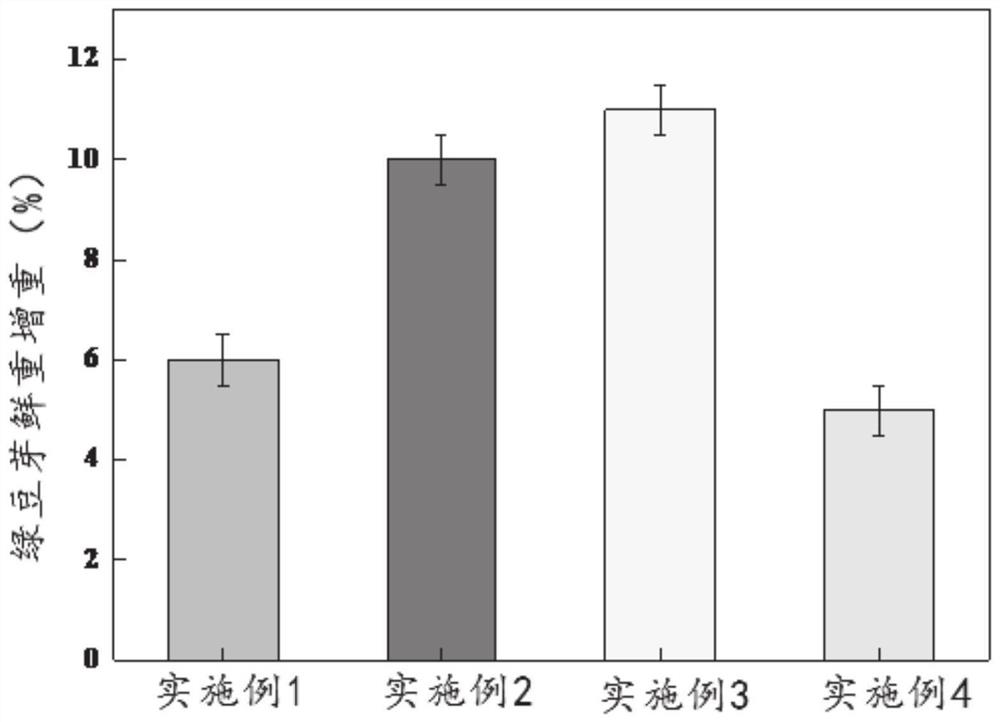

Embodiment 1

[0052]The straw is soaked in an alkaline activator for alkalization, and the soaking time is 6 hours; after soaking, the straw is put into a high-temperature reactor for pyrolysis and carbonization, and the temperature for pyrolysis and carbonization is 450°C.

[0053]The activated carbon obtained by carbonization is adsorbed with the exhaust gas, and the SO in the exhaust gas2The mass percentage of NO is 10%, the mass percentage of NO is 1‰, SO3The mass percentage content is 10%, NO2The mass percentage content is 0.5‰;

[0054]20 parts of activated carbon after adsorption saturation, pour into the compound solution of urea and ammonium phosphate. The compound solutions of urea and ammonium phosphate are urea aqueous solution and ammonium phosphate aqueous solution respectively. The mass concentration of urea solution is 1%, and the ammonium phosphate The mass concentration of the solution is 5%, and then 20 parts of bentonite and 20 parts of calcium sulfate are added, stirred and dried t...

Embodiment 2

[0057]The straw is soaked in an alkaline activator for alkalization, and the soaking time is 8h; after soaking, the straw is put into a high-temperature reactor for pyrolysis and carbonization, and the carbonization temperature is 500°C.

[0058]Activated carbon obtained by carbonization and waste gas are adsorbed; SO in waste gas2The mass percentage of NO is 15%, the mass percentage of NO is 2‰, SO3The mass percentage content is 15%, NO2The mass percentage content is 1‰;

[0059]30 parts of activated carbon after adsorption saturation, pour into urea and ammonium phosphate compound solution. The urea and ammonium phosphate compound solutions are urea aqueous solution and ammonium phosphate aqueous solution respectively. The concentration of the urea solution is 1.5% and the ammonium phosphate solution The concentration is 6%, and then add 20 parts of bentonite and 20 parts of calcium sulfate, stir and dry to obtain fertilizer.

[0060]SO after exhaust gas is adsorbed2The mass percentage of ...

Embodiment 3

[0062]The straw is soaked in an alkaline activator for alkalization, and the soaking time is 10h; after soaking, the straw is put into a high-temperature reactor for pyrolysis and carbonization, and the carbonization temperature is 550°C.

[0063]Activated carbon obtained by carbonization and waste gas are adsorbed; SO in waste gas2The mass percentage of NO is 20%, the mass percentage of NO is 3‰, SO3The mass percentage content is 15%, NO2The mass percentage content is 2‰;

[0064]After adsorbing 40 parts of saturated activated carbon, pour it into the compound solution of ammonium chloride and calcium phosphate. The compound solution of urea and ammonium phosphate is an aqueous solution of urea and an aqueous solution of ammonium phosphate respectively. The concentration of the urea solution is 2%, and the concentration of phosphoric acid The concentration of the ammonium solution is 8%, then 30 parts of bentonite and 30 parts of calcium sulfate are added, stirred and dried to obtain fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com