A composite material for sewage treatment with high adsorption performance

A sewage treatment and composite material technology, applied in the direction of adsorption water/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems that cannot realize the removal of small molecule heavy metal ions and organic phosphorus, and achieve the improvement of hydrophilicity ability, increase the adsorption capacity, and improve the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

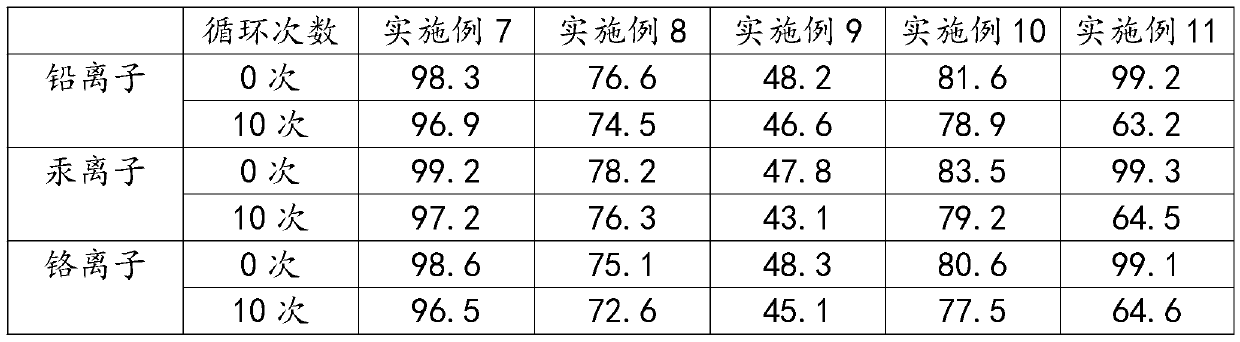

Examples

Embodiment 1

[0019] The specific preparation process of heavy metal adsorption fiber is as follows:

[0020] Step 1: Add 24.9g of triallyl isocyanurate into 225mL of ethanol solution, stir well and adjust the pH of the solution to 1 with acetic acid, then add 29.14g of ethylenedithiol into the reaction vessel, and stir at room temperature React for 7-8h, then evaporate to remove the solvent and unreacted ethanedithiol therein to obtain thiotriallyl isocyanurate;

[0021] Step 2: Add 10g of thiotriallyl isocyanurate prepared in the first step into 250mL of ethanol and stir to dissolve, then add 8.6g of azobisisobutyronitrile to it, and then heat up to 90-95°C , then drop 6.6g of acrylic acid into the reaction vessel through the dropping funnel, control the dropping rate to 9-10mL / min, stir and react for 1-1.5h after the drop is complete, then raise the temperature to 120-125°C and stir for 5-6h, The obtained product solution is evaporated to remove the solvent therein to obtain a carboxyl ...

Embodiment 2

[0024] The specific preparation process of heavy metal adsorption fiber is as follows:

[0025] Step 1: Add 24.9g of triallyl isocyanurate into 225mL of ethanol solution, stir evenly, adjust the pH of the solution to 1 with acetic acid, then add 19.41g of ethanedithiol to the reaction vessel, and stir at room temperature React for 7-8h, then evaporate to remove the solvent and unreacted ethanedithiol therein to obtain thiotriallyl isocyanurate;

[0026]Step 2: Add 10g of thiotriallyl isocyanurate prepared in the first step into 250mL of ethanol and stir to dissolve, then add 8.6g of azobisisobutyronitrile to it, and then heat up to 90-95°C , then drop 6.6g of acrylic acid into the reaction vessel through the dropping funnel, control the dropping rate to 9-10mL / min, stir and react for 1-1.5h after the drop is complete, then raise the temperature to 120-125°C and stir for 5-6h, The obtained product solution is evaporated to remove the solvent therein to obtain a carboxyl nitrog...

Embodiment 3

[0029] The specific preparation process of heavy metal adsorption fiber is as follows:

[0030] Step 1: Add 10g of triallyl isocyanurate to 250mL of ethanol and stir to dissolve it, then add 8.6g of azobisisobutyronitrile to it, then raise the temperature to 90-95°C, and then add to the reaction through the dropping funnel Add 6.6g of acrylic acid dropwise to the container, control the dropping rate at 9-10mL / min, stir for 1-1.5h after the dropwise addition is complete, then raise the temperature to 120-125°C and stir for 5-6h, evaporate the obtained product solution to remove the The solvent, obtains carboxyl nitrogen polymer;

[0031] Step 2: Add 10g of carboxyl nitrogen polymer into 80g of water, stir and dissolve to obtain an adsorption solution, add polyamide fibers into the adsorption solution, heat up to 60-70°C for 2-3 hours, and then filter to obtain heavy metal adsorption fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com