Surface glue removing and cleaning device for liquid crystal display polarizer

A technology for liquid crystal displays and cleaning devices, applied in cleaning methods, optics and instruments using liquids, can solve problems such as low efficiency and slow speed, and achieve the effects of high efficiency, high speed and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

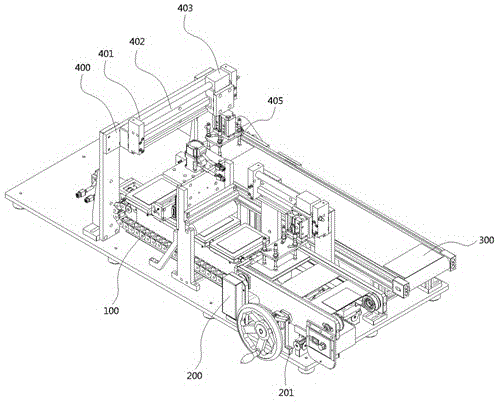

[0024] Please refer to figure 1 The device for removing glue on the surface of the polarizing plate of a liquid crystal display includes a discharge line 300 and a feed line 200. One end of the feed line 200 is provided with a squeegee mechanism 100, and the squeegee mechanism 100 and the discharge line 300 are arranged side by side. The third suction hand 405 and the second suction hand 111 of this embodiment are both vacuum suction cups.

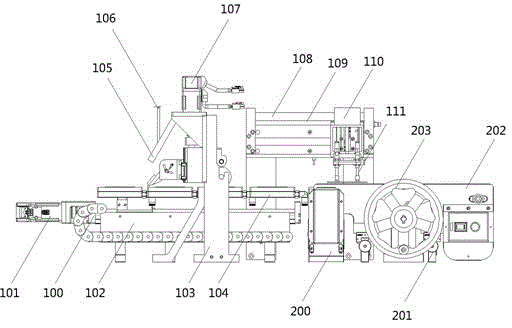

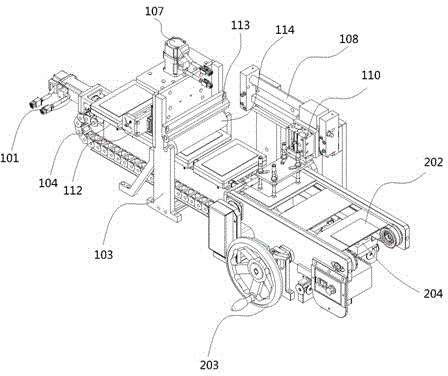

[0025] Please refer to figure 2 with image 3 The feed line 200 includes a belt transmission mechanism 202. The lower channel 204 is provided under the belt transmission mechanism 202. A track seat 201 is installed under the lower channel 204. The belt transmission mechanism 202 is installed on both sides of the track seat 201. A hand wheel 203 for adjusting the movement of the belt transmission mechanism 202 on the track base 201 is installed on one side of the belt transmission mechanism 202.

[0026] The polarizing plate is fed into the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com