Urban surface runoff filtration system

A surface runoff and urban technology, applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

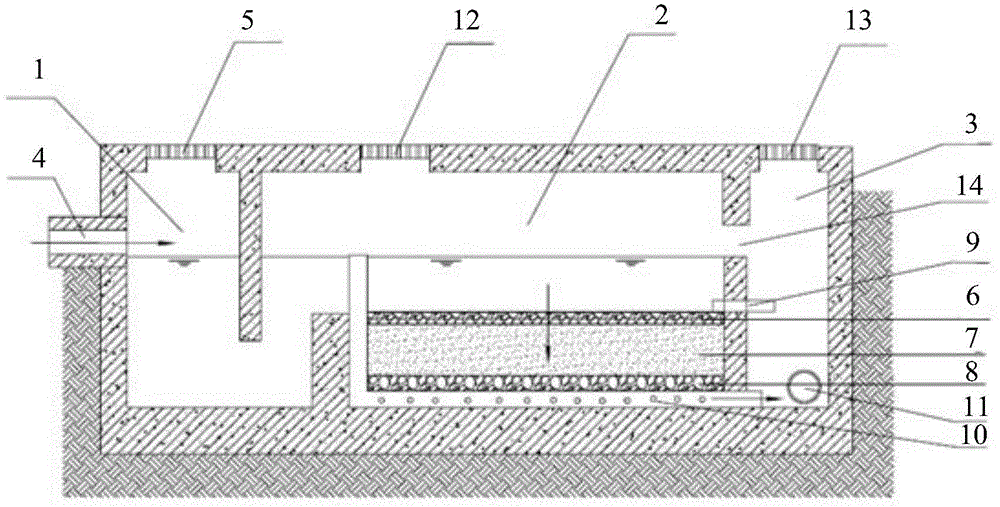

[0023] In order to effectively remove particulate pollutants in surface runoff and reduce urban surface runoff pollution without affecting the normal function of the surface, the present invention provides an urban surface runoff filtration system, the system comprising: a sedimentation chamber, the sedimentation chamber The chamber is used to remove large particle pollutants in the surface runoff by sedimentation; the filter chamber is used to filter and adsorb the surface runoff to remove small particle pollutants in the surface runoff; the drainage chamber is the The drainage chamber is used to discharge the filtered surface runoff through the drainage pipe.

[0024] The technical solution of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0025] This embodiment provides a kind of urban surface runoff filtration system, such as figure 1 As shown, the system includes: sedimentation chamber 1, filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com