Laminating machine for special glass

A special glass and laminating machine technology, applied in the field of glass processing, can solve the problems of increased labor, hidden safety hazards, and long-term presence of workers, and achieve the effect of improving production safety factor, product quality, and low failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

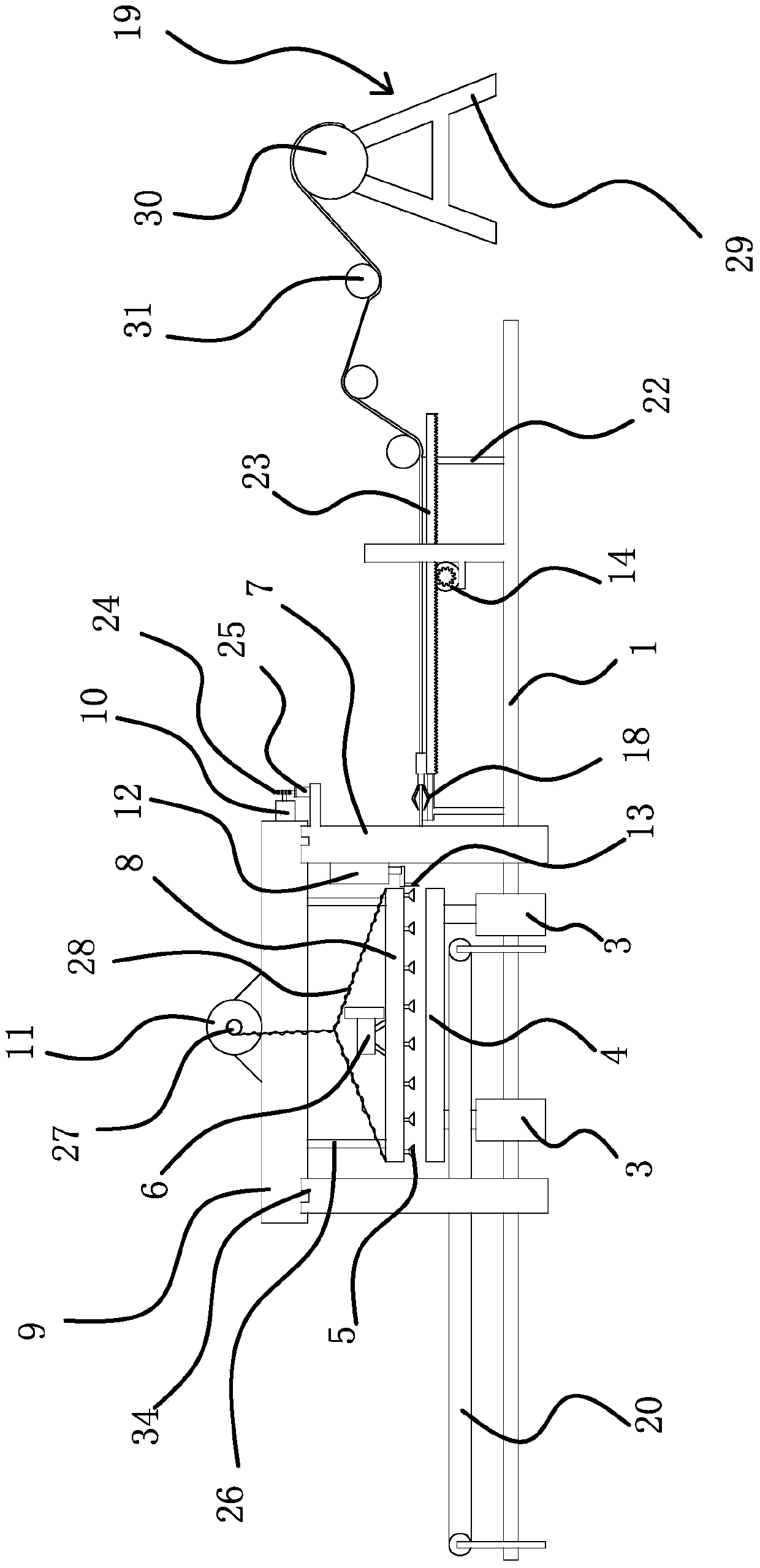

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

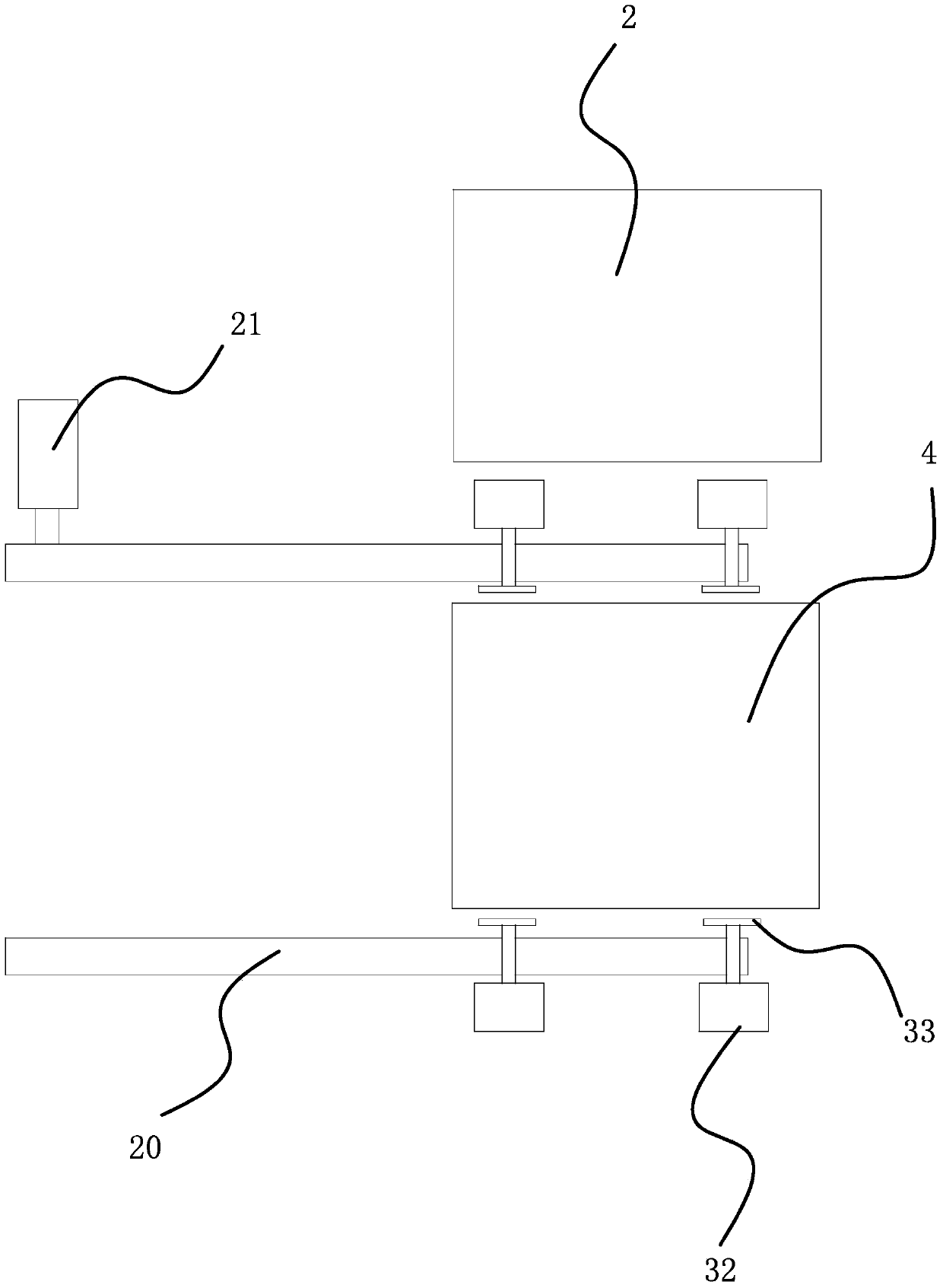

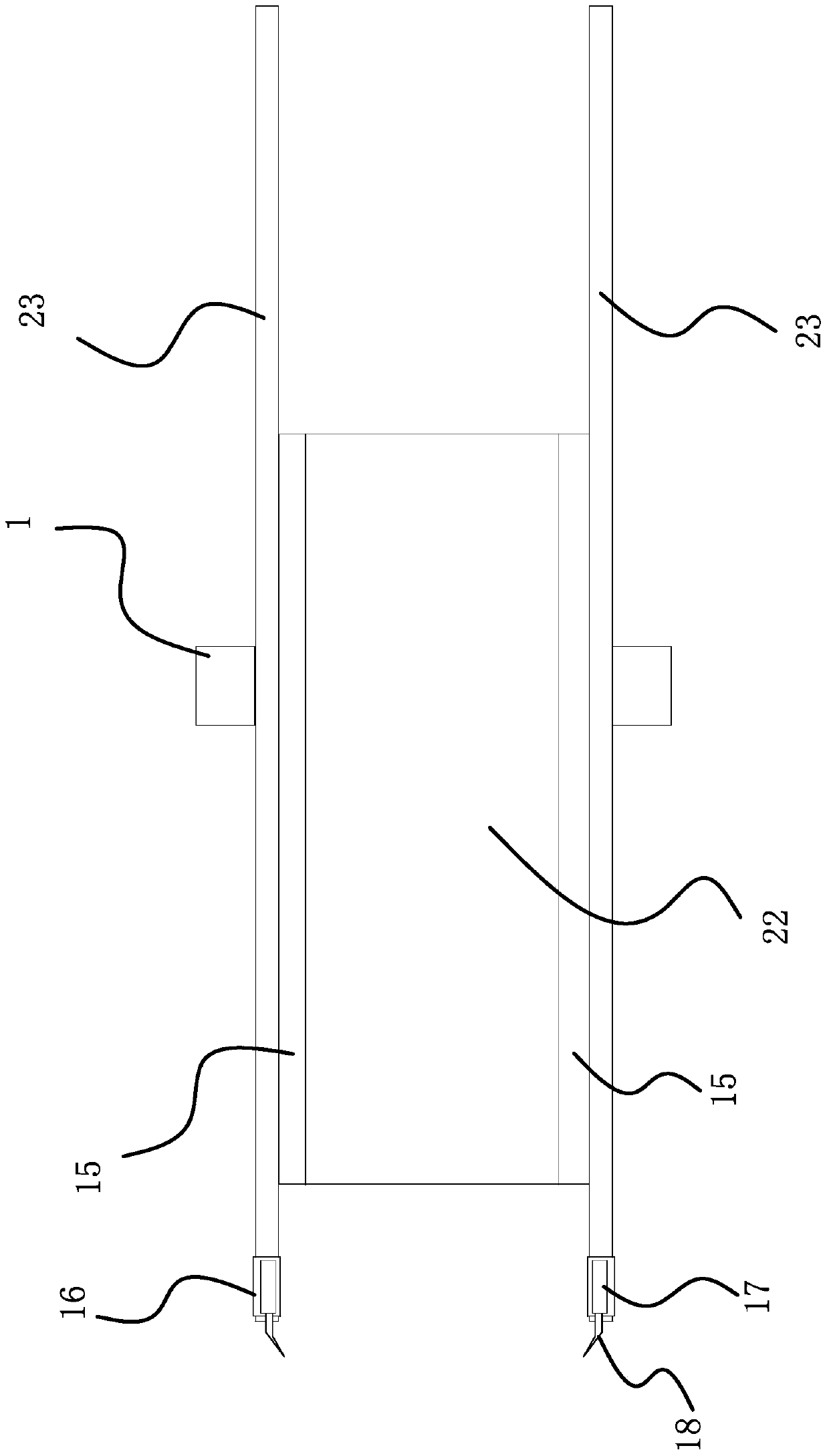

[0021] like figure 1 , figure 2 , image 3 As shown, the laminated special glass laminating machine is used for processing laminated special glass, including frame 1, material table 2, laminating platform, suction cup walking mechanism, film rack 19, automatic film conveying mechanism, cutter mechanism, Unloading mechanism.

[0022] The material platform 2 is used to place the special glass to be processed and is located at the side of the assembling platform. The assembling platform includes a lifting cylinder 3 and a lifting horizontal plate 4 fixed on the frame 1. The lifting horizontal plate 4 is located above the lifting cylinder 3 and is formed by Lifting cylinder 3 is driven for lifting action.

[0023] The suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com