A water-based zero-formaldehyde plywood adhesive

An adhesive and plywood technology, applied in the direction of adhesive, monocarboxylate copolymer adhesive, adhesive type, etc., can solve the problems of poor comprehensive performance and difficult operation, improve aging resistance, prevent adhesive layer The effect of shrinkage, excellent water and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

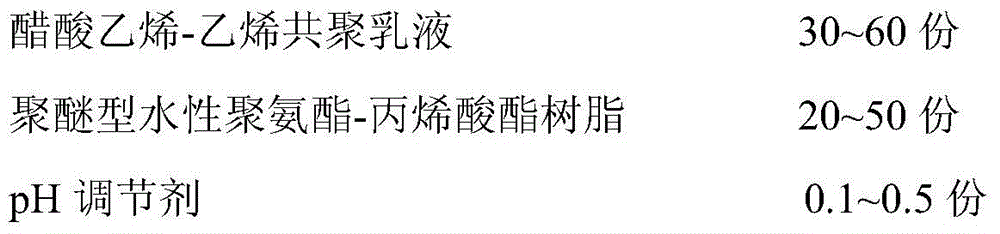

Method used

Image

Examples

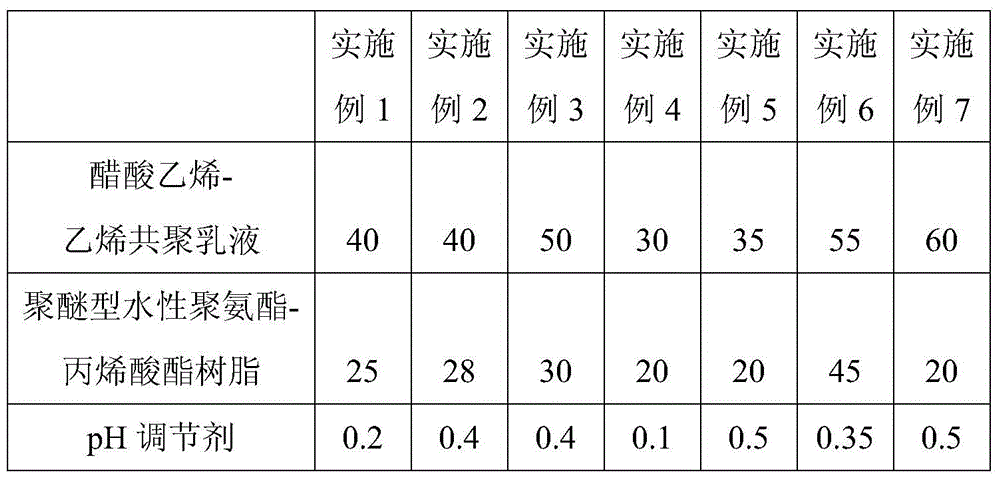

Embodiment 1

[0050] The vinyl acetate-ethylene copolymer emulsion in embodiment 1 is Celanese 1496; The polyether type water-based polyurethane-acrylic ester resin is Ketian chemical industry KTC701; The pH regulator is Guangzhou Yintian chemical YINTIAN-99, which is an organic alcohol amine; The pressure-sensitive adhesive is selected from FR-601 of Wuxi Changsheng, and its solid content is 50%, which is a silicone pressure-sensitive adhesive; the filler is heavy calcium carbonate; the curing agent is MDI-50; The agent is polyacrylamide, and its number-average molecular weight is 3 million; the thickener is Hemings 150, which is an aqueous alkali-swellable thickener; the defoamer is Airex902W.

Embodiment 2

[0051]The vinyl acetate-ethylene copolymer emulsion in Example 2 is Clariant Chemical Industry DI-4900; the polyether type water-based polyurethane-acrylate resin is Ketian Chemical KTC701; Ethanolamine; The pressure-sensitive adhesive is Zhongshan Dow self-adhesive, and its solid content is 55%, which is water-based polypropionate; The filler is 2500 mesh talcum powder; The curing agent is HMDI; The agent is Guangxi Tongxuan Rosin Emulsion 7050; the thickener is Deqian 1010, which is a water-based polyurethane associative thickener; the defoamer is BYK-044.

Embodiment 3

[0052] The vinyl acetate-ethylene copolymer emulsion in Example 3 is Celanese 8481; the polyether-type water-based polyurethane-acrylate resin is Ketian Chemical KTC701; the pH regulator is Hairun potassium methyl silicate BS168; the pressure-sensitive adhesive It is Danyang Zhongcai pressure-sensitive adhesive, its solid content is 54%, and it is water-based polyacrylate; the filler is ethyl cellulose; the curing agent is HDI; the tackifier is Guangxi Tongxuan TSR- 0065*50 water-based rosin thickening emulsion; the thickener is Hairun TS2751 water-based alkali-swellable acrylic thickener; the defoamer is DefomW-0506.

[0053] The adhesives in Examples 1 to 7 were prepared by a method comprising the following steps: First, adjust the pH of the vinyl acetate-ethylene copolymer emulsion to 7.0 with a pH regulator, add fillers to disperse and beat until there are no obvious small particles, and then mix with The polyether-based water-based polyurethane-acrylate resin is mixed slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com