Yarrow yeast fa2-3 from the ocean and its low-temperature amylase and enzyme production method

A technology of low-temperature amylase and yarrow yeast, applied in the field of microorganisms, can solve the problems of reducing the efficiency of microorganisms decomposing organic pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

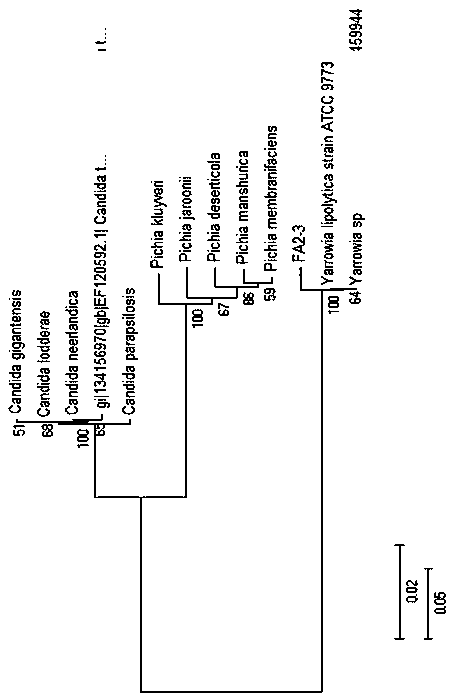

[0080] Embodiment 1, a kind of Yarrow yeast ( Yarrowia sp . ) FA2-3, CGMCC No. 10377. This bacterial strain has the following characteristics: bacterial strain FA2-3 is oblong, singly disperses, budding reproduction (see figure 1 ). The colonies are white with neat edges. The growth characteristics of strain FA2-3 are as follows: the growth temperature range of the strain is 15-35°C, and the optimum growth temperature is 30°C; the growth pH range is 5.0−10.0, and the optimum growth pH is 7.0; It can grow in the range of 8%, and the optimum growth NaCl concentration is 0.5%.

Embodiment 2

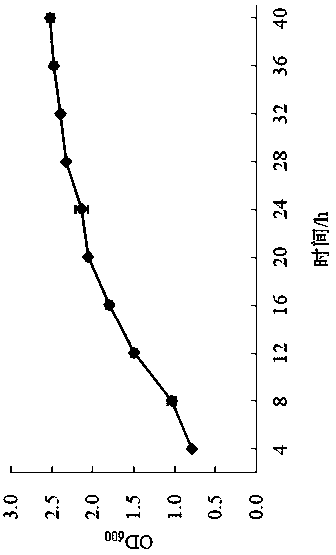

[0081] Embodiment 2, a method for producing low-temperature amylase from Yarrowia FA2-3 from the ocean as described in Example 1, the steps are as follows: inoculate the slant seeds of Yarrowia FA2-3 into YPD medium, 30 ℃, 150 r / min, liquid volume 20%, cultivated for 12 hours to obtain seed liquid; inoculated the seed liquid with 4% inoculum in the enzyme-producing medium, 150 r / min, 25°C for 20 h, 10000 r / min Centrifuge for 5 minutes, and take the supernatant, which is the low-temperature amylase crude enzyme solution.

Embodiment 3

[0082] Embodiment 3, a kind of low-temperature amylase produced by the method for producing low-temperature amylase from the oceanic Yarrow yeast FA2-3 as described in embodiment 2, the character of described low-temperature amylase is: the minimum of low-temperature amylase The suitable temperature is 30°C, and it still has enzyme activity at 0°C; the optimum pH is 8.0. The enzyme has good thermal stability at 30°C, and still has 85.8% enzyme activity in 5 hours, and the enzyme is stable at pH 4.0-9.0; Ba 2+ , Ca 2+ , Mg 2+ and Sr 2+ Activation of enzymes, NH 4+ 、Cu 2+ 、Co 2+ There are varying degrees of inhibition of enzymes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com